Intelligent emission reduction system based on polymorphic information fusion

A polymorphic and intelligent technology, applied in general control systems, control/regulation systems, comprehensive factory control, etc., can solve problems such as similarity, dissimilarity, blank space, etc., to solve the problem of small samples, reduce pollution problems, The effect of maintaining safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

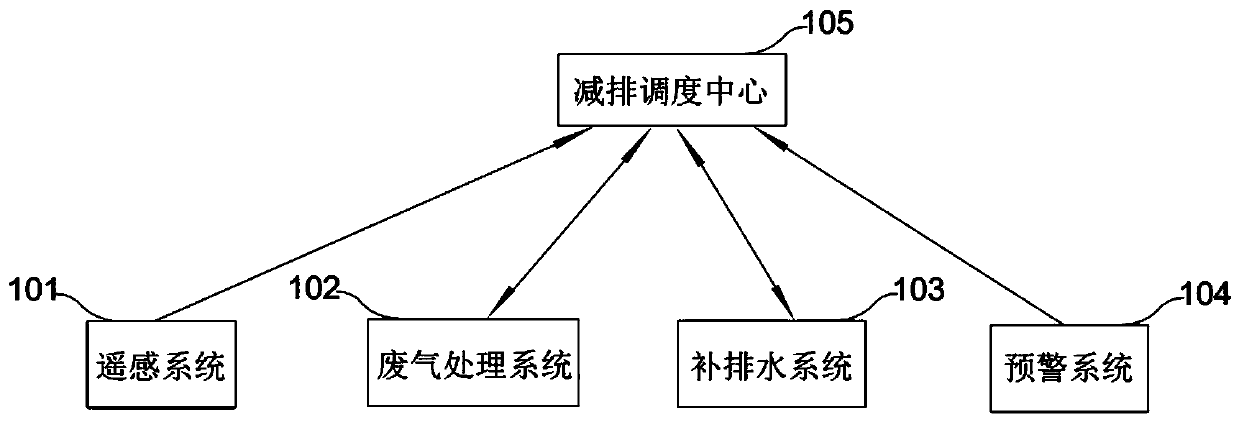

[0027] This embodiment provides a structural diagram of an intelligent emission reduction system based on multi-modal information fusion. Such as figure 1 As shown, the structure is as follows:

[0028] S101 Remote Sensing System: Used to obtain the thermal environment data of the steel production area, transmit the thermal environment data to the emission reduction dispatching center, obtain the second thermal environment data of the steel production area after the first set time, and send the second thermal environment data Transmission to the emission reduction dispatch center;

[0029] Optionally, the thermal environment data and the second thermal environment data are thermal infrared remote sensing data and thermal infrared load parameters. When the emission reduction dispatching center receives the thermal environment data and / or the second thermal environment data, it inverts the temperature of the steel production area. Surface temperature field, call the background...

Embodiment 2

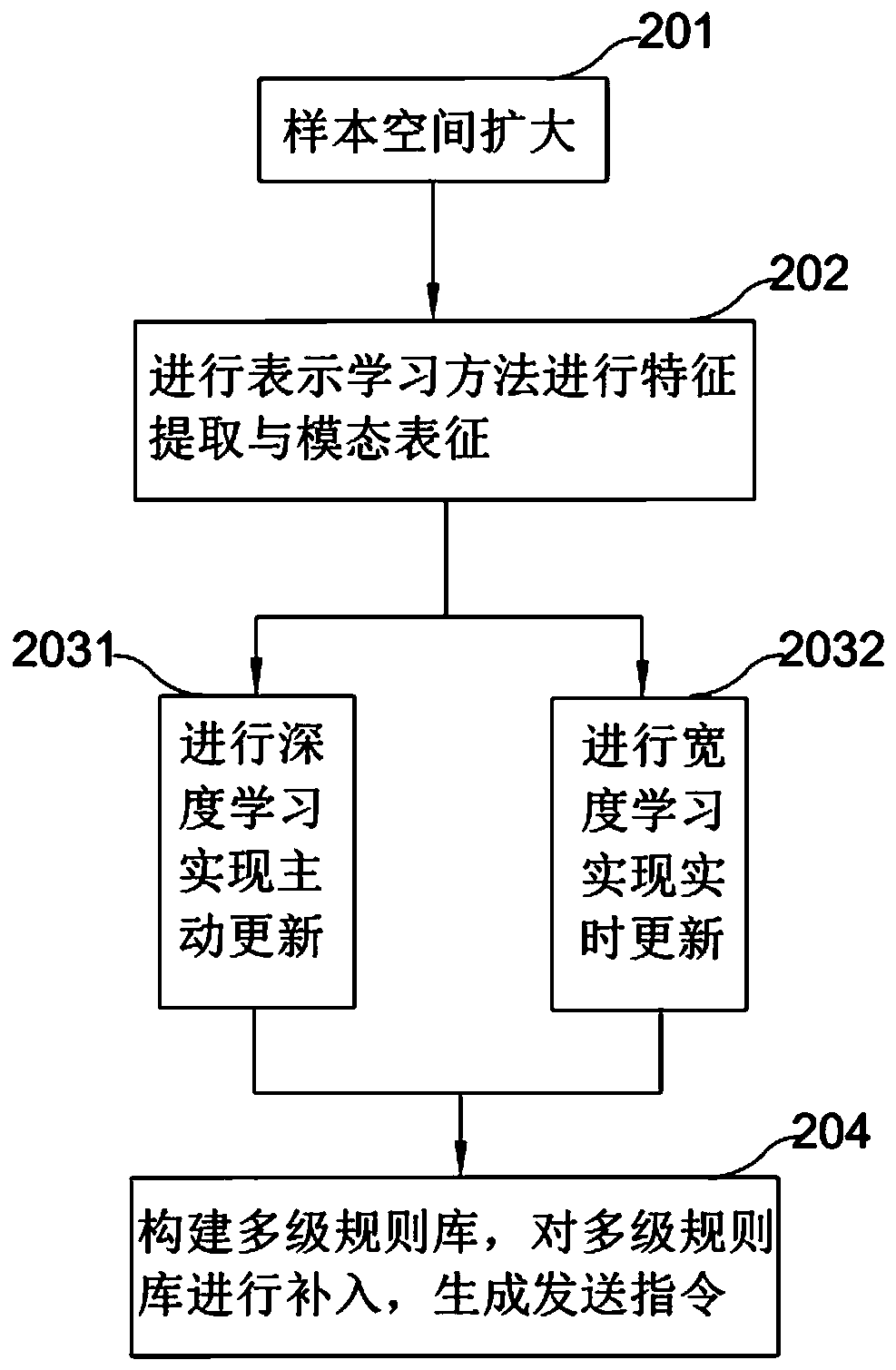

[0037] This embodiment provides a multi-modal information fusion method, which is used in an intelligent emission reduction system based on multi-modal information fusion. Such as figure 2 As shown, the method includes the following steps:

[0038] S201 Expansion of sample space: Carry out sample learning on the thermal environment data, the first data group and the third data group to realize the expansion of the sample space, and carry out network structure design and network parameter training;

[0039] Optionally, analyze the thermal environment data, the first data group and the third data group according to the probability generation model, realize the transformation from small sample space to large sample space, and realize the expansion of sample space;

[0040] Optionally, the multiplexing degree of the thermal environment data, the first data group and the third data group is increased to improve the learning ability of small samples.

[0041] S202 performing feat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com