Method for extracting pure electric truck battery pack support structure road load spectrum

A road load spectrum and support structure technology, applied in the field of new energy vehicles, can solve problems such as reducing development costs, shortening the development cycle, quantifying the fatigue life of battery pack support structures, and achieving accurate calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

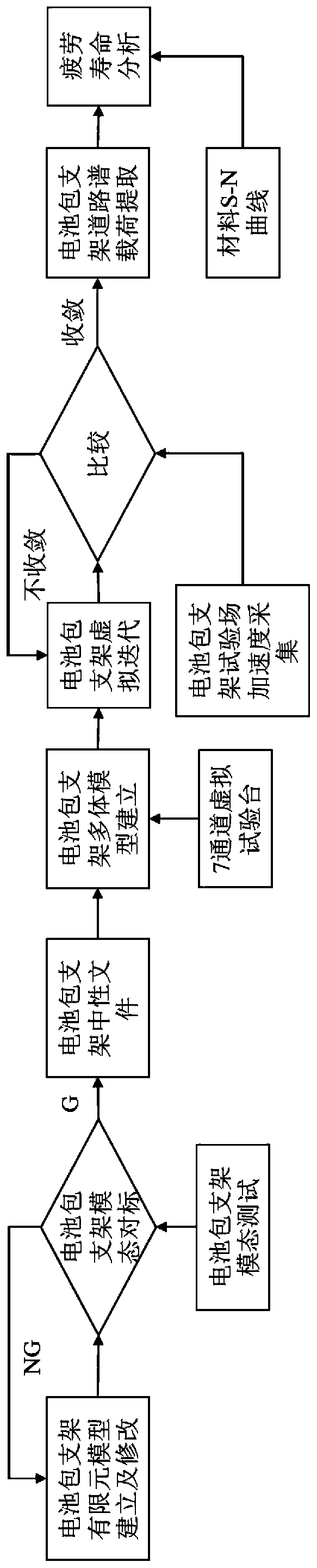

[0035] The following is attached with the manual Figure 1-17 , the battery pack support structure of a certain pure electric truck type is taken as an example to illustrate the main process of the present invention:

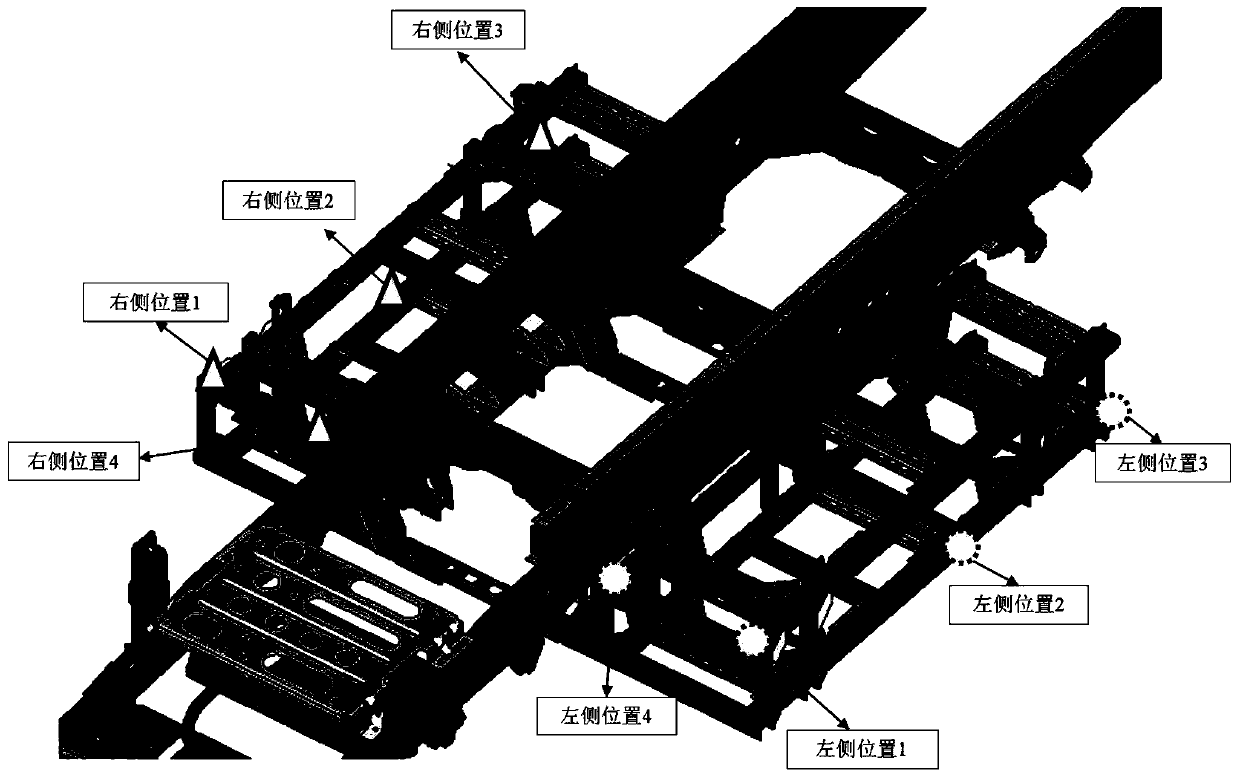

[0036] (1) Acceleration signal acquisition of battery pack support structure test site

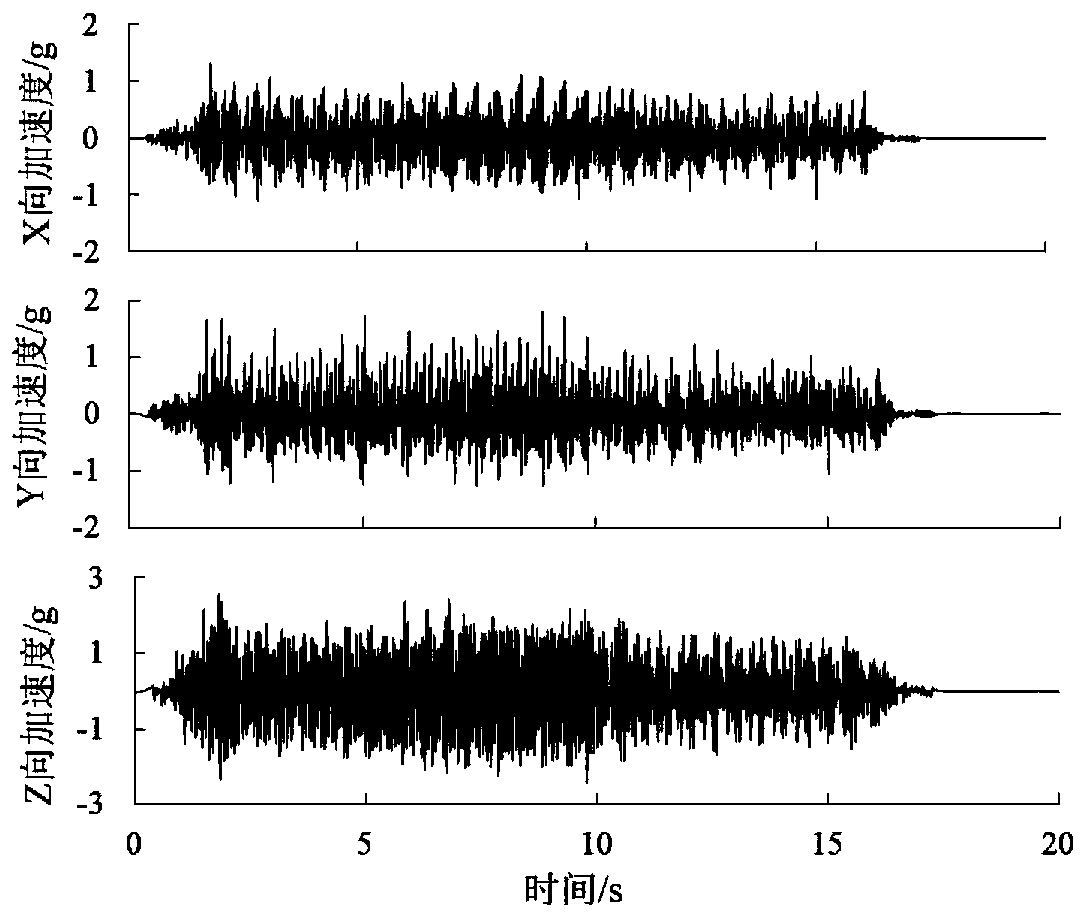

[0037] Acceleration signal collection is performed on the key areas of the vehicle frame and battery pack support structure on the bad roads of the test site. The bad roads mainly include: washboard road, Belgium, twisted road and long wave road, etc. The layout of the acceleration sensor is as follows: figure 2 As shown, four three-dimensional acceleration sensors are arranged on the left and right sides to measure the three-dimensional acceleration of the battery pack support structure, and provide target response signals for the virtual iteration of step 4. image 3 It is the time-domain signal of acceleration in three directions at position 1 on the left side when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com