Production process method for printing imbricated cell string

A production process and battery technology, which is applied to circuits, photovoltaic power generation, electrical components, etc., can solve problems that affect product quality and product appearance, fail to realize the shingling process, and reduce the utilization efficiency of cells, so as to shorten equipment downtime and maintenance Time, avoid waste of production and use, and improve the effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

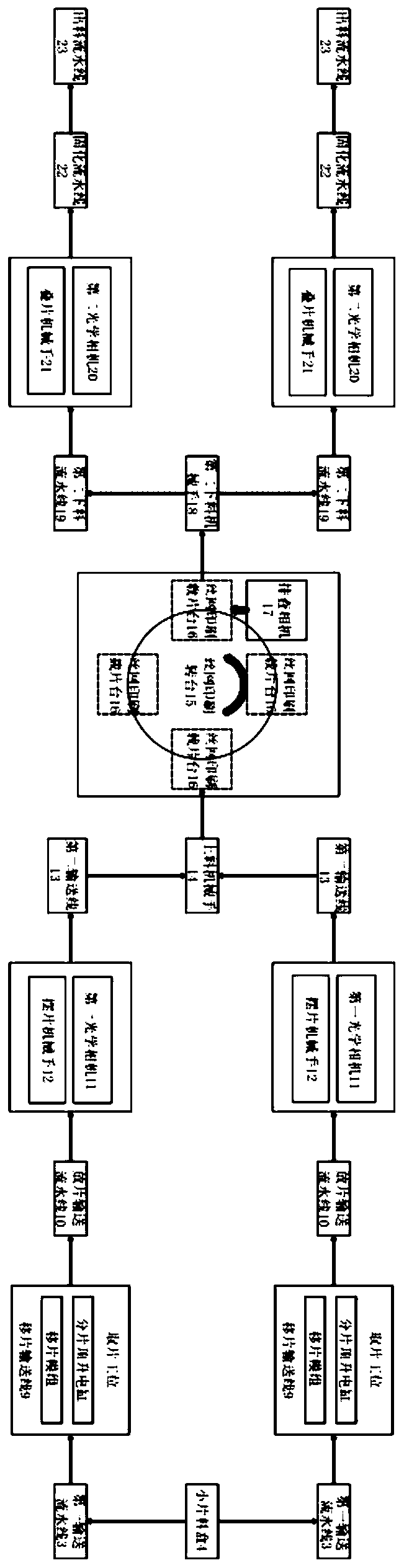

[0035] Such as Figure 1 ~ Figure 4 As shown, a production process method of a printed shingled battery string of the present invention, the production process steps are:

[0036] S1. Cut and break the entire battery sheet 1, divide it into at least two small battery sheets 2, and extract it to the first conveying line 3 for conveying;

[0037] Specifically, the following steps are included:

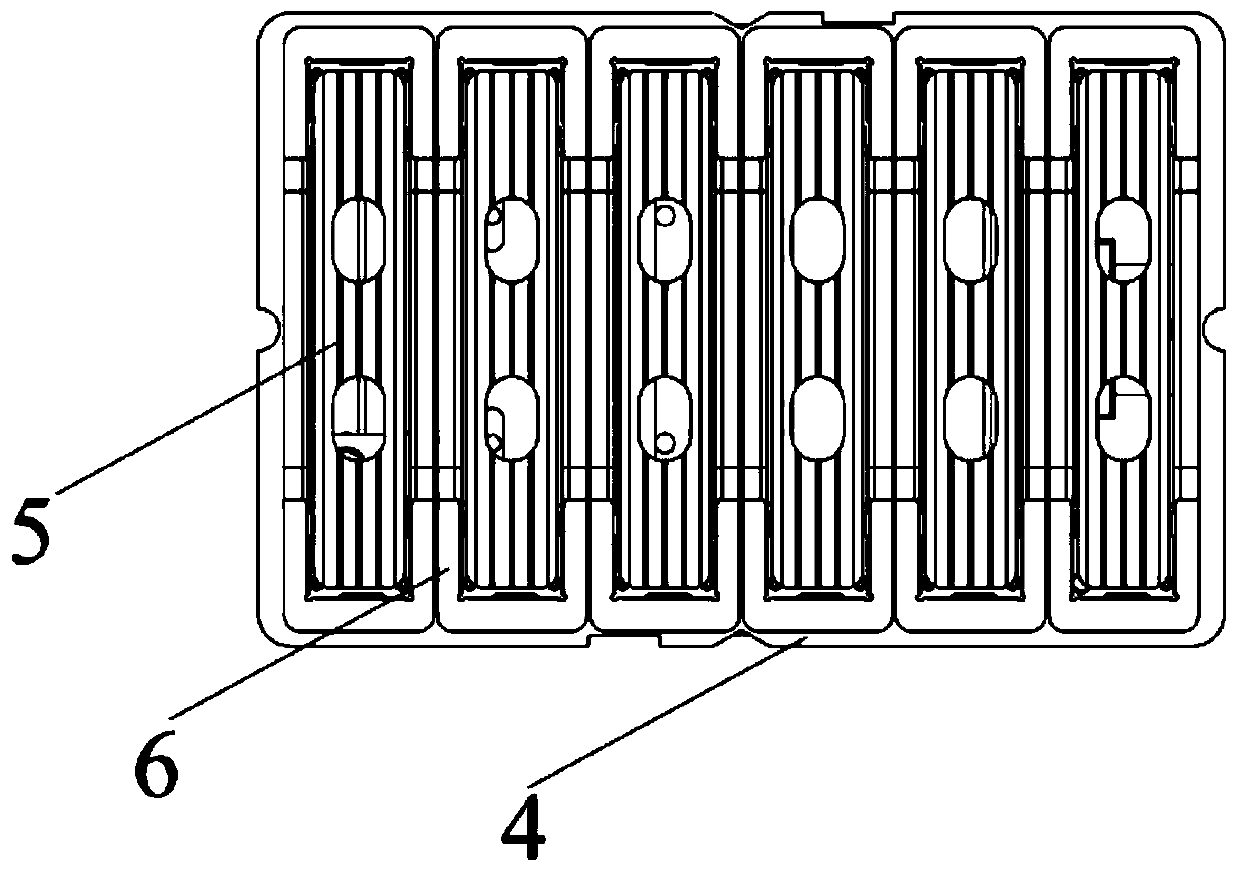

[0038] S1.1. First, laser cut the entire battery sheet 1, and form a laser scribe on the battery sheet 1;

[0039] S1.2. Divide the entire battery sheet 1 into six equal parts of the battery sheet 2 along the laser scribe groove. Specifically, it can be divided into multiple equal parts of the battery sheet 2 according to the actual situation, and place the battery sheet 2 with the front facing up. On the small piece pallet 5 in the small piece material box 4, the small piece material box 4 is placed on the first conveying assembly line 3, wherein, what adopt in the present embodiment ...

Embodiment 2

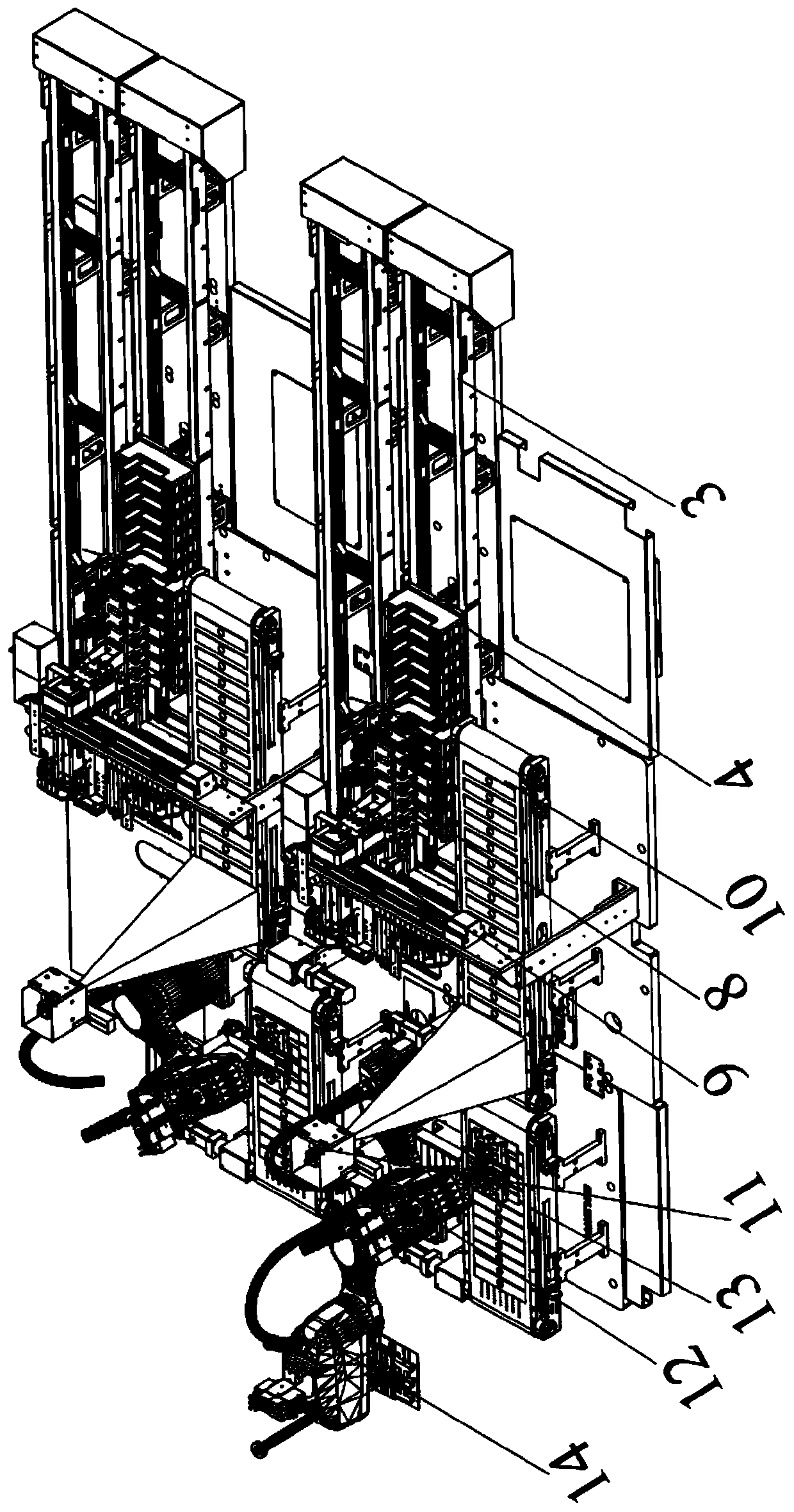

[0050] like Figure 5 , Figure 6 As shown, a production process method of a printed shingled battery string of the present invention, the production process steps are:

[0051] S1. Cut and break the entire battery sheet 1, divide it into at least two small battery sheets 2, and extract it to the first conveying line 3 for conveying;

[0052] Specifically, the following steps are included:

[0053] S1.1. Put the unprocessed whole cell 1 with the reverse side upwards into the loading box 24, and the loading box 24 is transported to the loading station through the loading line 7, and 5 loading boxes can be buffered on the loading line 7 Box 24, a feeding jacking cylinder is provided at the feeding station, and a feeding pallet is placed at the bottom of the feeding box 24, and the feeding jacking cylinder is arranged below the feeding pallet, and the battery sheet 1 in the feeding box 24 Push out the feeding box 24 through the feeding jacking cylinder until it reaches the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com