PSA decarbonization tail gas desulfurization technology

A desulfurization process, decarbonization tail gas technology, applied in gas treatment, dispersed particle filtration, membrane technology, etc., can solve the problems of purification gas and desorption gas purity and CO2 recovery rate cannot be taken into account, CO2 excess, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

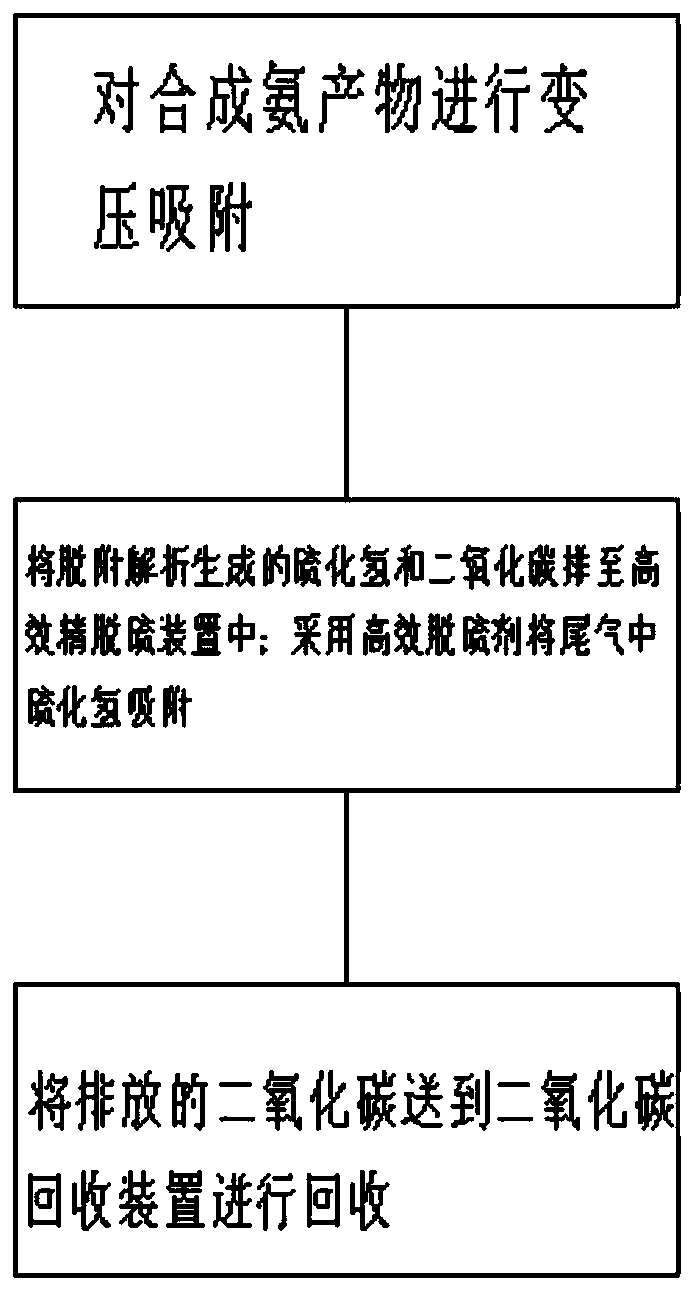

[0026] A PSA decarburization tail gas desulfurization process, comprising the following steps:

[0027] S1, performing pressure swing adsorption on the synthetic ammonia product;

[0028] S2. Discharge hydrogen sulfide and carbon dioxide generated by desorption and analysis to a high-efficiency fine desulfurization device; use a high-efficiency desulfurizer to absorb hydrogen sulfide in the tail gas;

[0029] S3, sending the discharged carbon dioxide to a carbon dioxide recovery device for recovery;

[0030] When the high-efficiency desulfurizer is used for a period of time, the activity decreases, and the desulfurizer should be regenerated.

[0031] In this technical solution, the regeneration of the desulfurizer can continuously replenish the desulfurizer, so that the hydrogen sulfide in the tail gas can be efficiently and stably continuously adsorbed, and then high-purity carbon dioxide can be obtained. In a specific embodiment, high-purity carbon dioxide can be further p...

Embodiment 2

[0038] The difference from Example 1 is that the adsorbent of the pressure swing adsorption includes fruit shell-based activated carbon, and the shell-based activated carbon is modified with metal ions, and the adsorption effect of the shell-based activated carbon is better after modification. Experiments show that: CU 2+ and Mg 2+ The modification effect of mixed metal ions exceeds that of CU 2+ and Mg 2+ Use alone. Therefore, the husk-based activated carbon undergoes CU 2+ and Mg 2+ Mixed metal ion modification. Further experiments showed that the CU 2+ and Mg 2+ When the mixing ratio is 8:2, the adsorption effect of the modified shell-based activated carbon is better.

[0039] Preferably, the high-efficiency desulfurizer is an iron oxide-based high-temperature gas desulfurizer. Experiments show that the regeneration environment parameters of the iron oxide-based high-temperature gas desulfurizer are temperature 400°C and space velocity 3700h -1 , The oxygen conten...

Embodiment 3

[0042] The difference from Example 1 is that the adsorbent of the pressure swing adsorption includes fruit shell-based activated carbon, and the shell-based activated carbon is modified with metal ions, and the adsorption effect of the shell-based activated carbon is better after modification. Experiments show that: CU 2+ and Mg 2+ The modification effect of mixed metal ions exceeds that of CU 2+ and Mg 2+ Use alone. Therefore, the husk-based activated carbon undergoes CU 2+ and Mg 2+ Mixed metal ion modification. Further experiments showed that the CU 2+ and Mg 2+ When the mixing ratio was 9:1, the adsorption effect of the modified shell-based activated carbon was better.

[0043] Preferably, the high-efficiency desulfurizer is an iron oxide-based high-temperature gas desulfurizer. Experiments show that the regeneration environment parameters of the iron oxide-based high-temperature gas desulfurizer are temperature of 580°C and space velocity of 3900h -1, The oxygen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com