Grinding dispersant for thermal sublimation ink

A dispersant and thermal sublimation technology, which is applied in the field of grinding dispersant, can solve problems such as nozzle blockage, color imbalance, image color density reduction, etc., and achieve the effect of meeting printing requirements, good dispersion and stability, and low foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

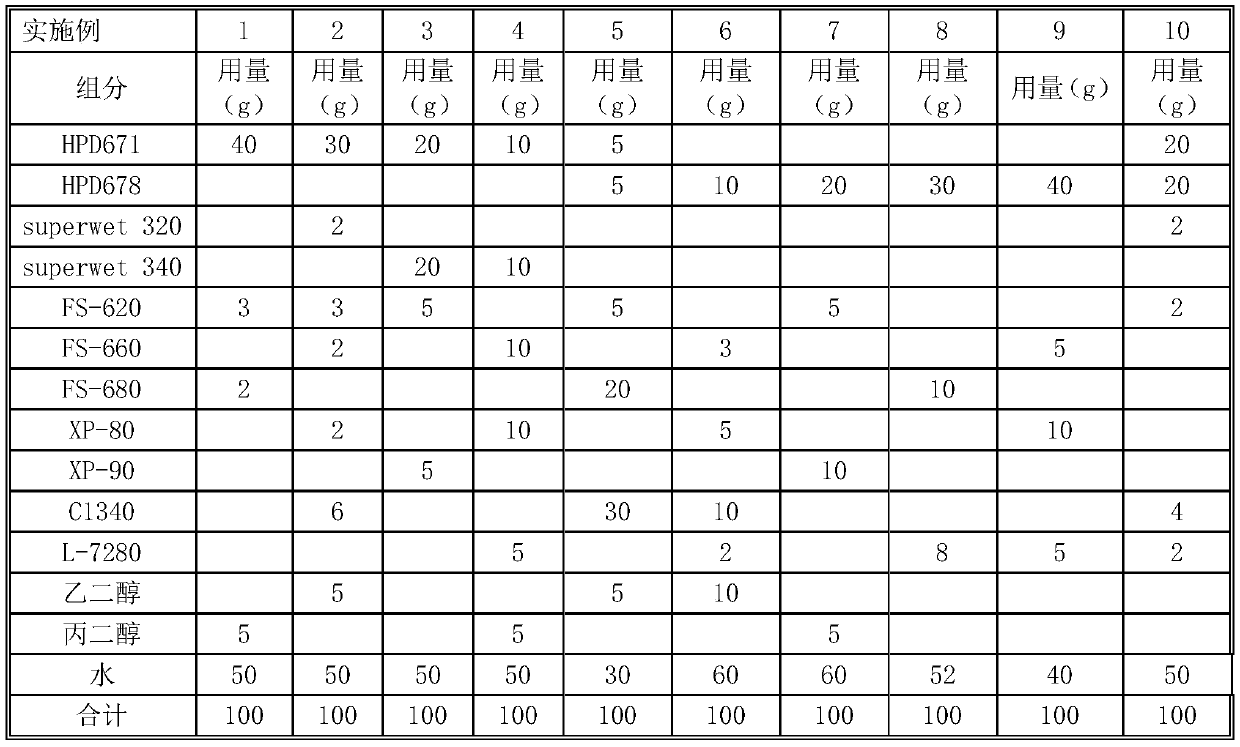

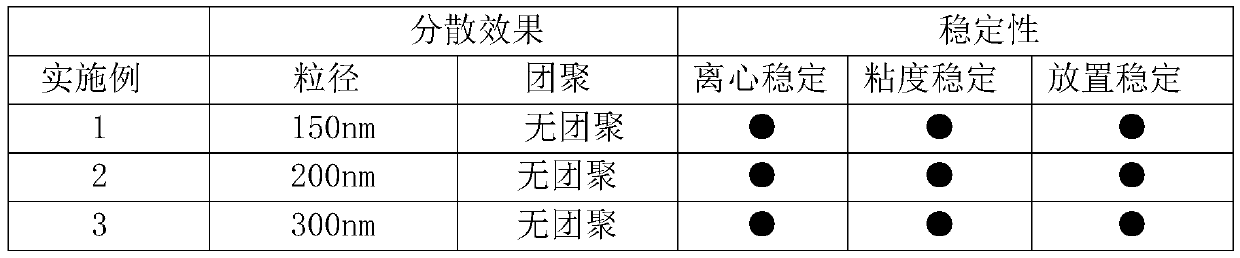

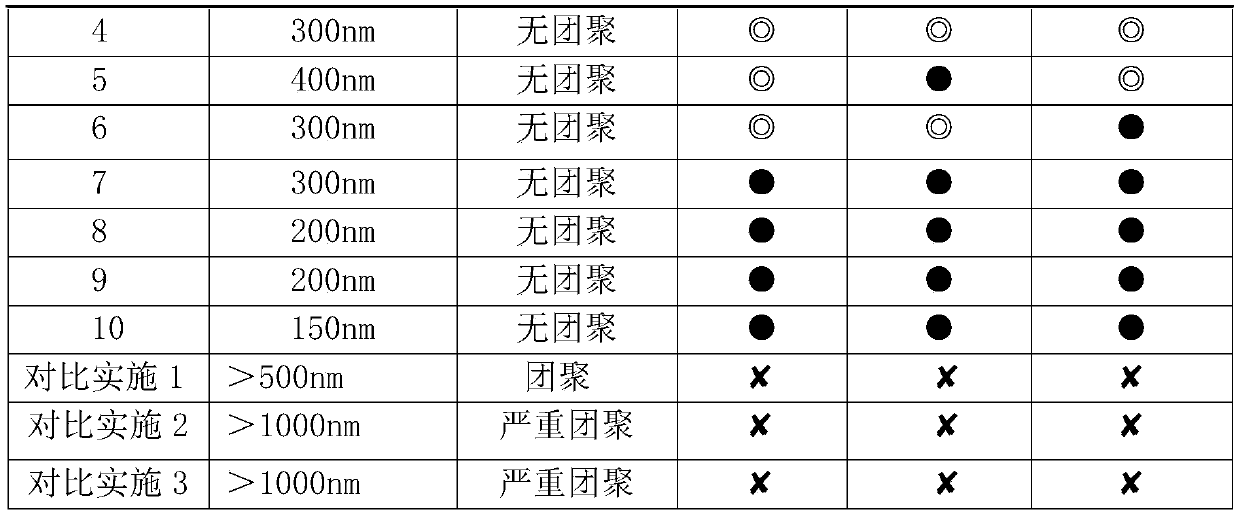

[0026] The present invention will be described in further detail below in conjunction with specific examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention, and in no way limit the protection scope of the present invention.

[0027] Among them, the component names are as follows:

[0028] Acrylic type resins (HPD671 and HPD678 from: BASF)

[0029] 2,5,8,11-Tetramethyl-6-dodecynol-5,8-diol polyether (Tu Yi Le superwet-320 / 340, produced by Tianjin Hepfill New Material Co., Ltd.);

[0030] 2,4,7,9-Tetramethyl-5-decynediol-4,7 diol polyether (Tuyile FS-620 / 640 / 660 / 680, produced by Tianjin Hepfiler New Material Co., Ltd.) ;

[0031] Isomerized alcohol polyethers of C8-C10 (Lutensol XP-80, XP-90, produced by: BASF Co., Ltd. BASF);

[0032] Isomerized C13 alcohol polyoxyethylene ether (Multiso C1340, produced by: Sasol (China) Chemical Co., Ltd.);

[0033] Polyether-modified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com