An automatic flip surface detection and floating hair adsorption device in the middle of a scarf

A technology of surface detection and automatic flipping, which is applied in the direction of flipping objects, removing floating yarns, transportation and packaging, etc. It can solve the problems of low detection efficiency, large labor force, and high labor intensity of manual detection, so as to improve detection efficiency and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

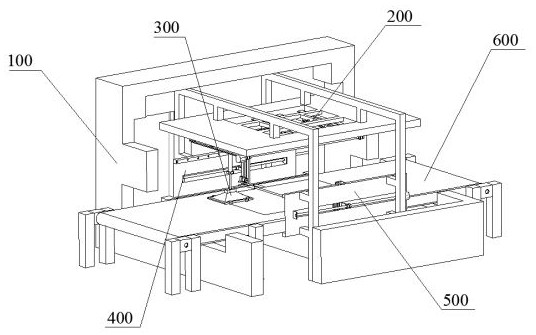

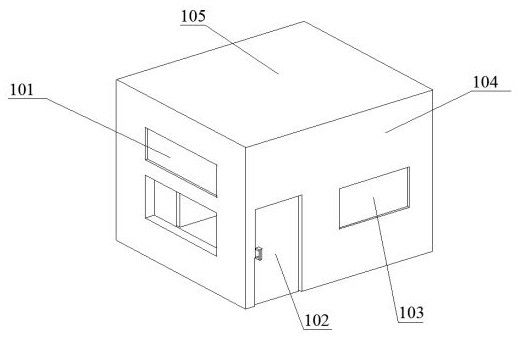

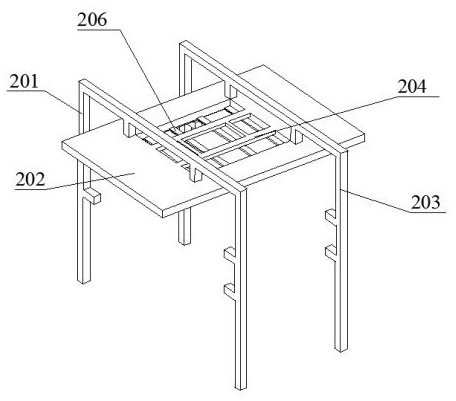

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11, as shown in FIG. 12 , the automatic turning surface detection and floating hair adsorption device in the middle of the scarf includes a darkroom module 100 , a visual detection module 200 , a floating hair adsorption module 300 , a bottom turning shaft module 400 , a top turning shaft module 500 , and a conveying module 600 , is characterized in that: the front view observation window 101 is at the entry position of the conveyor belt 601, the darkroom door 102 and the side view observation window 103 are installed on the side protection wall 104, the top protection wall 105 is located on the upper part to close the entire turning mechanism, and the front support legs 201 and the rear support leg 203 are fixed to the top cover 202 by welding, and the lighting tubes 206 are scattered on the bottom of the top cover bracket 204 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com