Box pulling device, material transporting robot and material transporting method

A material and output shaft technology, applied in the field of box-drawing devices, can solve problems such as low work efficiency, achieve the effects of improving work efficiency, simplifying work, and ensuring success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

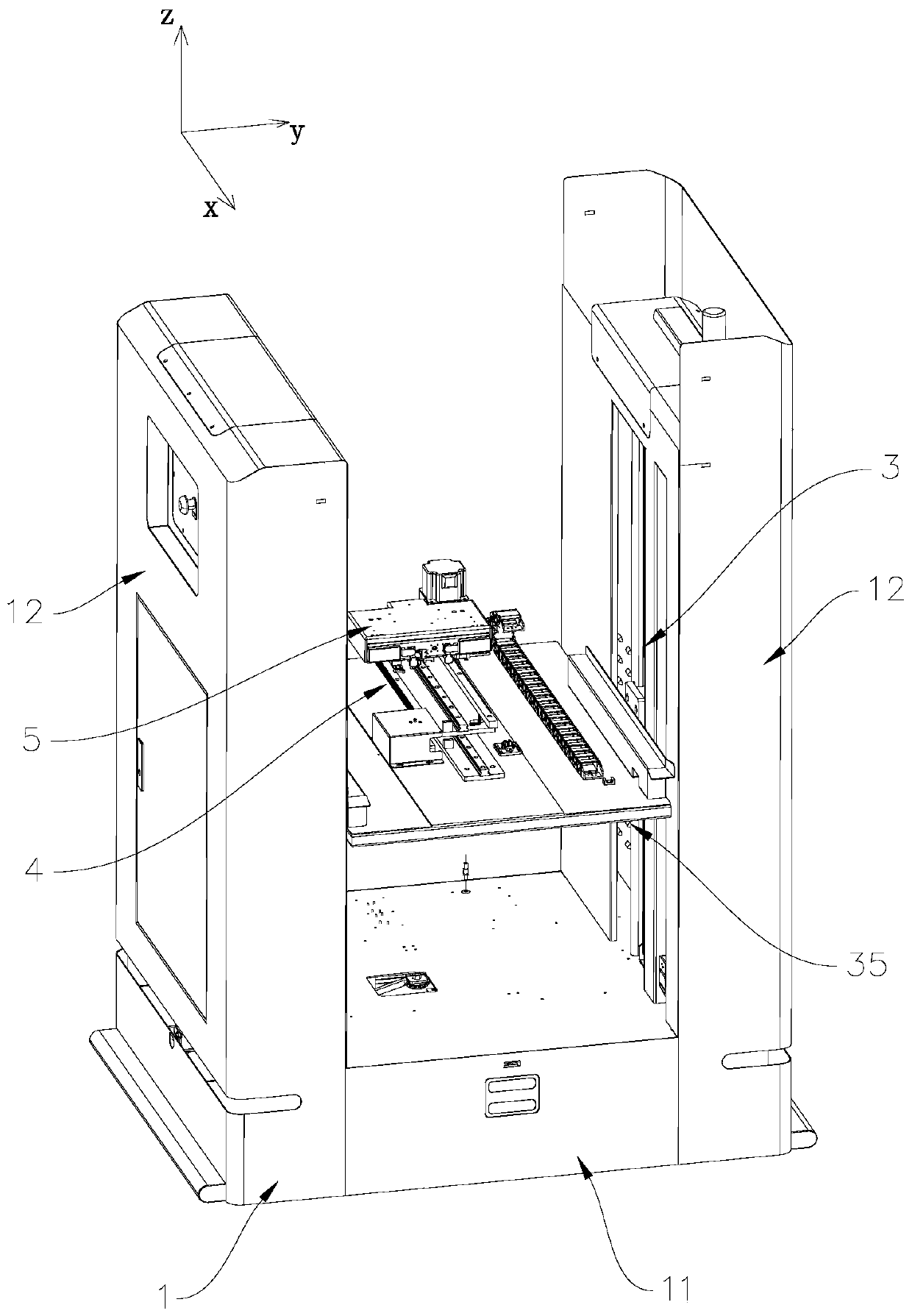

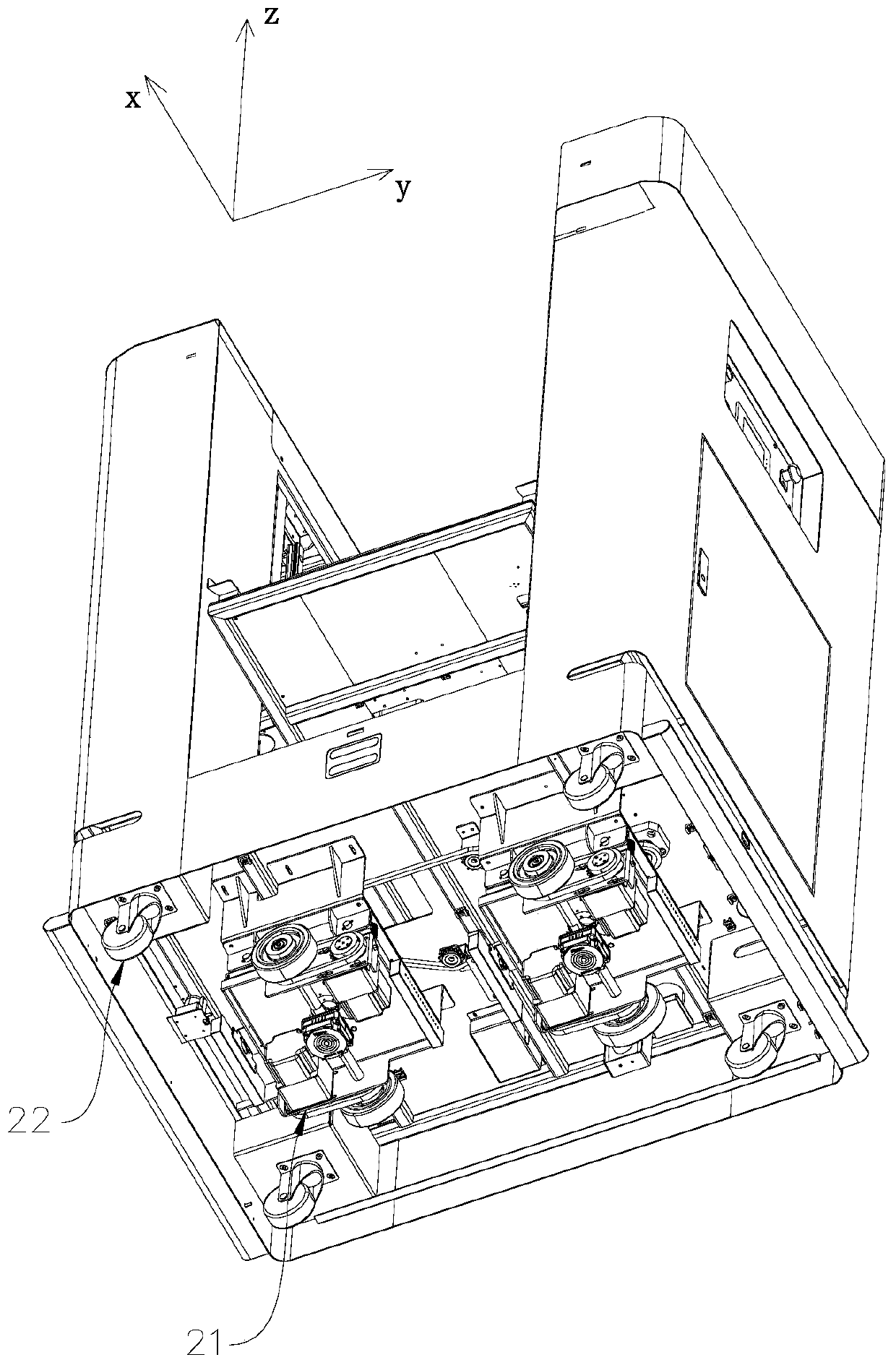

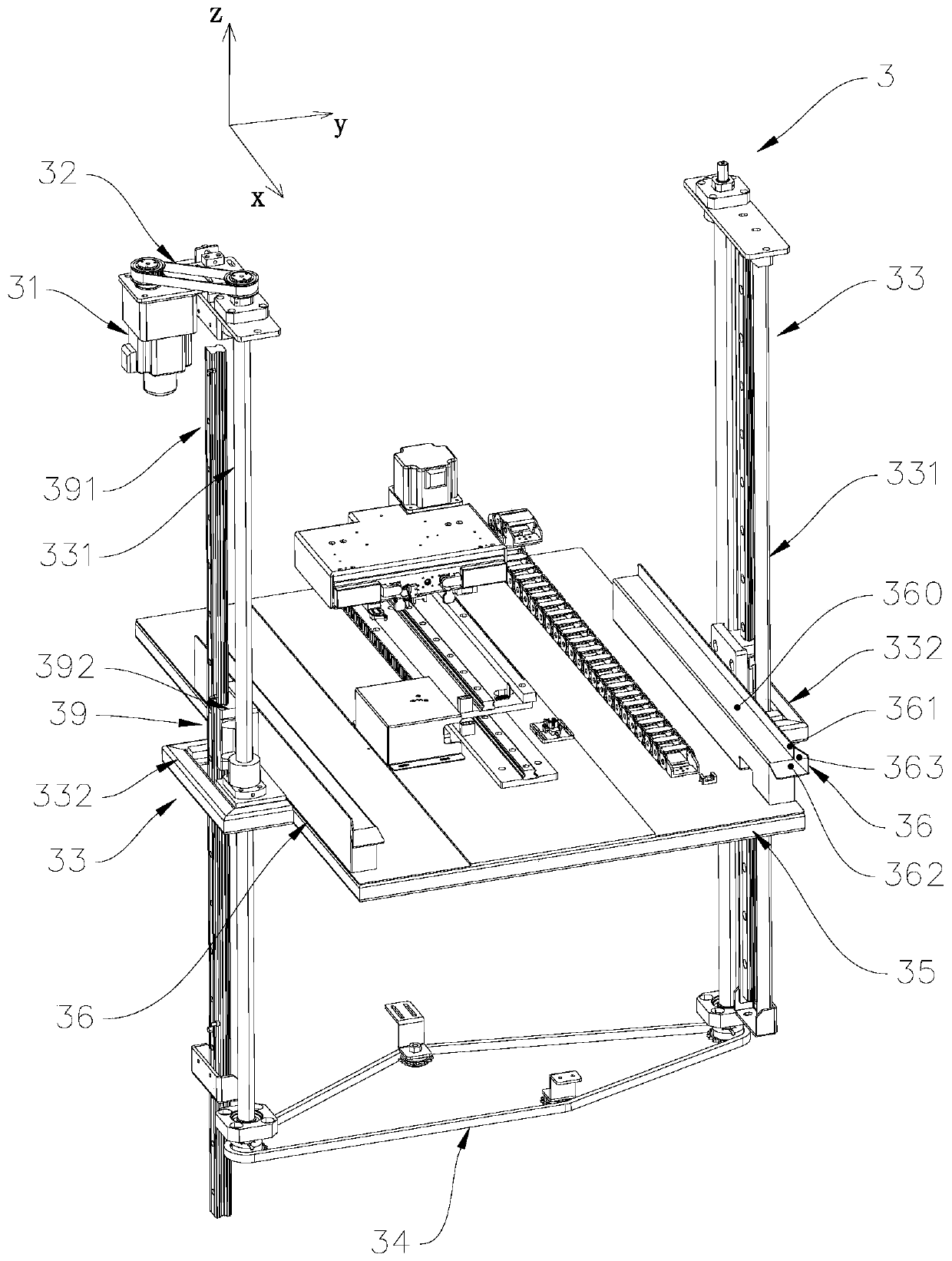

[0045] see figure 1 and figure 2 , figure 1 and figure 2It is a structural diagram of the first viewing angle and the second viewing angle of the material transportation robot embodiment of the present invention. The material transport robot comprises a body 1, a drive wheel assembly 21, a supporting wheel set 22, a lifting device 3, a slide rail assembly 4 and a box pulling device 5, the lifting device 3 is installed on the top of the body 1, and the lifting device 3 includes a lifting platform 35, the sliding The rail assembly 4 is installed on the lifting platform 35 , and the box pulling device 5 is installed on the slide rail assembly 4 .

[0046] The body 1 is in the shape of a "bow", and the body 1 is composed of a base 11 and two side walls 12. The side walls 12 stand on both sides of the base 11 in the transverse direction (y-axis direction). The X-axis direction runs through; the driving wheel assembly 21 and the supporting wheel group 22 are installed at the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com