Emergency control system and crane

An emergency control and main system technology, applied in cranes, fluid pressure actuation system safety, mechanical equipment, etc., can solve problems such as crane danger, tipping, loss, etc., meet the requirements of heat dissipation, ensure safety, and realize pressure relief Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

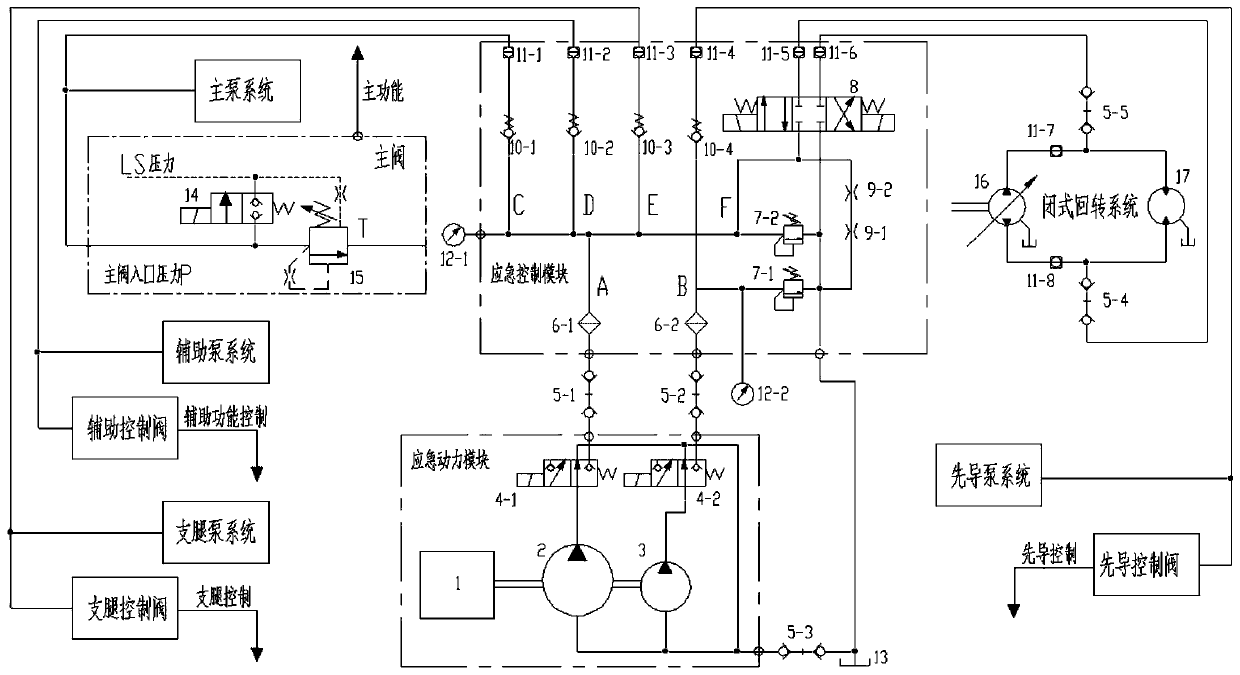

[0052] In some embodiments, such as figure 1 As shown, an emergency control system includes a motor 1, an emergency main pump 2, an emergency pilot pump 3, an electric control reversing valve 4, a quick change joint, a filter, an overflow valve 7, an electric control reversing reversing valve 8, Damping, one-way valve, ball valve, pressure gauge, oil tank 13, electric control switch valve 14, unloading valve 15, rotary two-way variable pump 16, rotary motor 17; systems and auxiliary systems.

[0053] An emergency control system, including an emergency power module, an emergency control module, the emergency power module and the emergency control module are designed separately, and the emergency power module and the emergency control module are connected through a first quick connector 5-1 and a second quick connector 5-2 , the emergency control module is fixed on the chassis of the crane under normal conditions, and a fixed connection pipeline is provided for easy connection,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com