Lightweight flame retardant sponge and preparation method and application thereof

A lightweight and sponge technology, applied in the field of lightweight flame retardant sponge and its preparation and application, can solve the problem that the demand for lightweight filling materials cannot be met, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

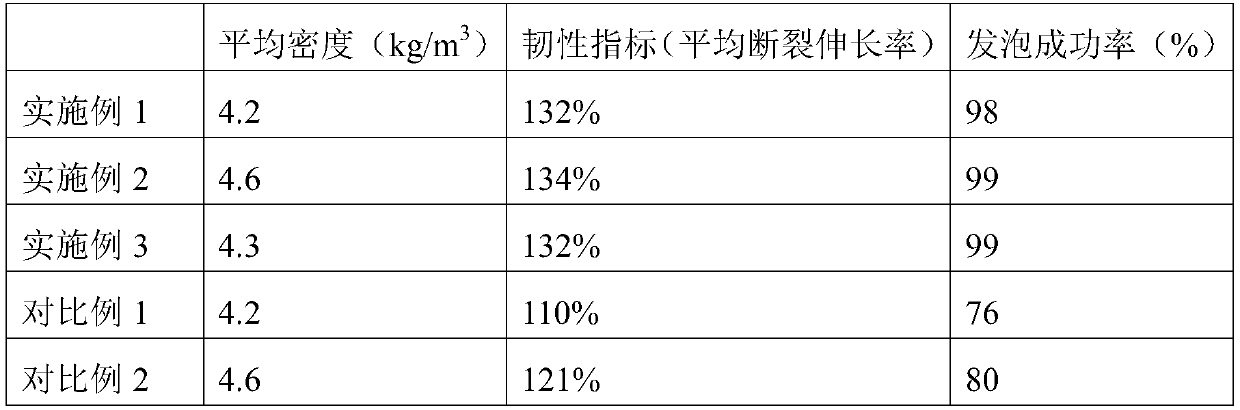

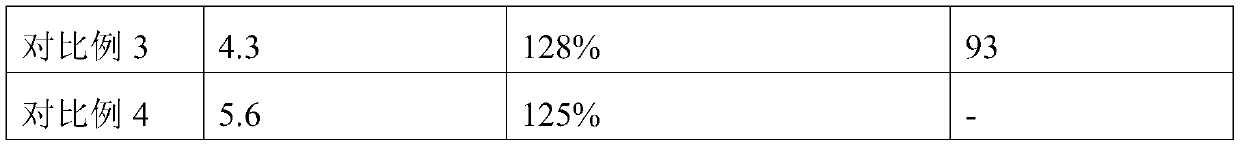

Examples

preparation example Construction

[0048] The present invention also provides a method for preparing a lightweight flame-retardant sponge, the steps of which include:

[0049] Temperature control and stirring of polyether polyol PPG and toluene diisocyanate TDI of corresponding mass parts;

[0050] Stir and mix the temperature-controlled and stirred polyether polyol PPG and toluene diisocyanate TDI and the remaining components of the corresponding mass parts to form a sponge foam;

[0051] The obtained sponge body is subjected to aging treatment.

[0052] Further, the steps of the method also include: cutting the cured lightweight flame-retardant sponge according to customer requirements.

[0053] Further, the control temperature of the temperature control is 23-25°C; this temperature range is limited to the optimum foaming temperature of the above components, and the foaming is relatively stable if the temperature is limited within this range.

[0054] Further, the stirring speed during the temperature contr...

Embodiment 1

[0060] The lightweight flame retardant sponge of this embodiment is formed by foam molding and aging treatment of the following corresponding parts by mass, including: polyether polyol PPG: 100 parts; toluene diisocyanate TDI: 110 parts; Combustion agent: 0.4 parts; catalyst: 0.6 parts; silicone oil: 6 parts; dichloromethane: 90 parts; water: 12 parts; antioxidant: 0.4 parts; plasticizer: 1 part; heat stabilizer: 0.4 parts; glycerin : 1 part; wherein, the catalyst comprises odorless amine and gelling agent; wherein, the mass percentage of the odorless amine is 60%, and the remainder is gelling agent.

[0061] Control and stir the corresponding mass parts of polyether polyol PPG and toluene diisocyanate TDI; the control temperature of temperature control is 23-25°C; the stirring speed is 5 rpm; the stirring time is 11 minutes .

[0062]Stir and mix the temperature-controlled and stirred polyether polyol PPG and toluene diisocyanate TDI and the remaining components of the corre...

Embodiment 2

[0068] The lightweight flame retardant sponge of this embodiment is formed by foam molding and aging treatment of the following corresponding parts by mass, including: polyether polyol PPG: 100 parts; toluene diisocyanate TDI: 120 parts; Combustion agent: 0.8 parts Catalyst: 1 part; Silicone oil: 8 parts; Dichloromethane: 110 parts; Water: 15 parts; Antioxidant: 0.8 parts; Plasticizer: 1.5 parts; Heat stabilizer: 0.8 parts; 1.5 parts; Wherein, comprise odorless amine and gelling agent in the catalyst; Wherein, the mass percent of described odorless amine is 70%, the remainder is gelling agent.

[0069] Control and stir the corresponding mass parts of polyether polyol PPG and toluene diisocyanate TDI; the control temperature of temperature control is 23-25°C; the stirring speed is 15 rpm; the stirring time is 15 minutes .

[0070] Stir and mix the temperature-controlled and stirred polyether polyol PPG and toluene diisocyanate TDI and the remaining components of the correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com