Five-membered ring static dissipative copolyester and its preparation method and application

A technology of electrostatic dissipation and copolyester, which is applied in the field of polyester, can solve problems such as unstable mechanical and thermal properties, and decreased crystallization properties, so as to maintain stable mechanical and thermal properties, improve mechanical properties, and change regularity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

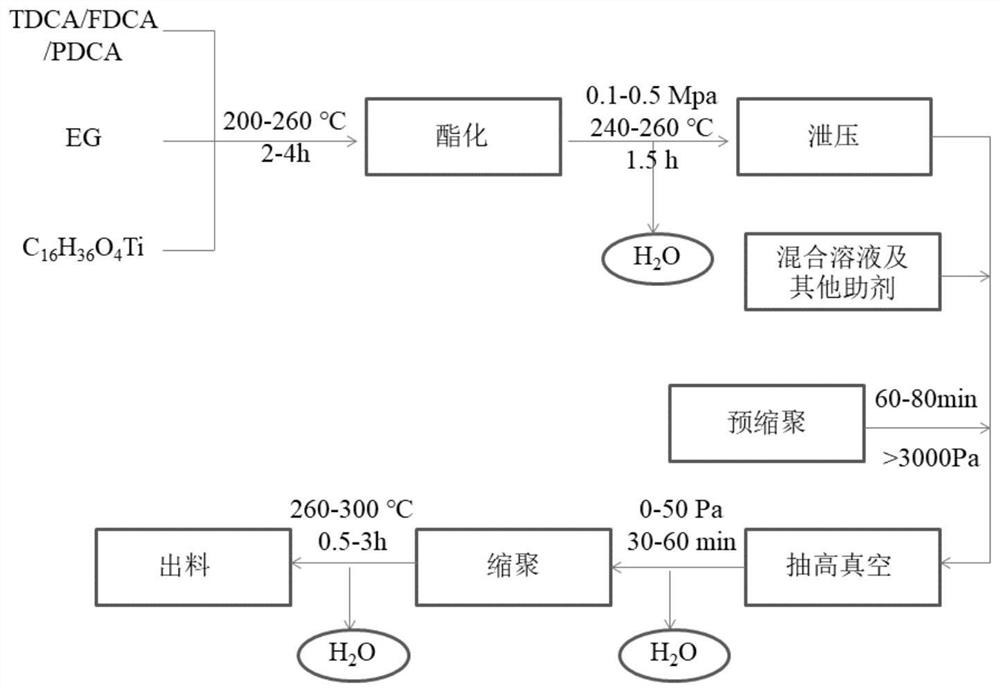

[0054] The preparation flow chart of five-membered ring static dissipative copolyester of the present invention is as follows figure 1 As shown, the specific content is as follows:

[0055] (1) Esterification process stage:

[0056] The present invention introduces 2,5-thiophene dicarboxylic acid (TDCA), 2,5-furandicarboxylic acid (FDCA) and / or 2,5-pyrrole dicarboxylic acid (PDCA) in the esterification process section, and ethylene glycol ( EG) esterification reaction, the reason is that the aromaticity and structural symmetry of TDCA are weaker than that of the benzene ring, and the presence of a sulfur atom containing a lone pair of electrons in the thiophene ring increases the polarity of TDCA.

[0057] Therefore, the five-membered ring copolyester polyester material can be prepared by replacing TDCA; in addition, TDCA will increase the chemical polarity of the five-membered ring copolyester material and endow it with static dissipative properties.

[0058] (2) Condensati...

Embodiment 1

[0081] (1) In a 5L stainless steel autoclave, add 1032.9g 2,5-thiophene dicarboxylic acid (TDCA), 595.2g ethylene glycol (EG), 2g tetrabutyl titanate, and replace the air in the autoclave with nitrogen , carry out the esterification reaction at 240°C-250°C and 0.3-0.4MPa, and when no more water evaporates, release the pressure to normal pressure.

[0082] (2) 200g PEG 6000, 0.1g cobalt acetate, 0.28g phosphoric acid, 0.6g triphenyl phosphite, 75g bishydroxyethyl isophthalate-5-sodium sulfonate (SIPE) and 120g ethylene glycol (EG ) mix, stir evenly, add to the reaction kettle, raise the temperature to 270°C, gradually reduce the absolute pressure in the kettle to below 50Pa, and the reaction time is 2-3 hours until the viscosity of the system does not rise any more.

[0083] (3) After the reaction is finished, feed nitrogen gas to extrude the obtained melt, pelletize and dry to obtain five-membered ring copolyester static dissipative thiophene dicarboxylate ethylene glycol este...

Embodiment 2

[0086](1) In a 5L stainless steel autoclave, add 516.45g 2,5-thiophene dicarboxylic acid (TDCA), 468.27g 2,5-furandicarboxylic acid (FDCA), 595.2g ethylene glycol (EG), 2g titanium For tetrabutyl ester, after introducing nitrogen to replace the air in the kettle, carry out esterification reaction at 240°C-250°C and 0.3-0.4MPa, and release the pressure to normal pressure when no more water evaporates.

[0087] (2) Mix 0.1g of cobalt acetate, 0.28g of phosphoric acid, 0.6g of triphenyl phosphite with 120g of ethylene glycol (EG), stir evenly, add to the reaction kettle, raise the temperature to 270°C, and gradually The absolute pressure drops below 50Pa, and the reaction time is 2-3 hours until the viscosity of the system no longer rises.

[0088] (3) After the reaction is finished, feed nitrogen gas to press out the melt, pelletize and dry to obtain five-membered ring copolyester static dissipative thiophene dicarboxylate ethylene glycol ester chips.

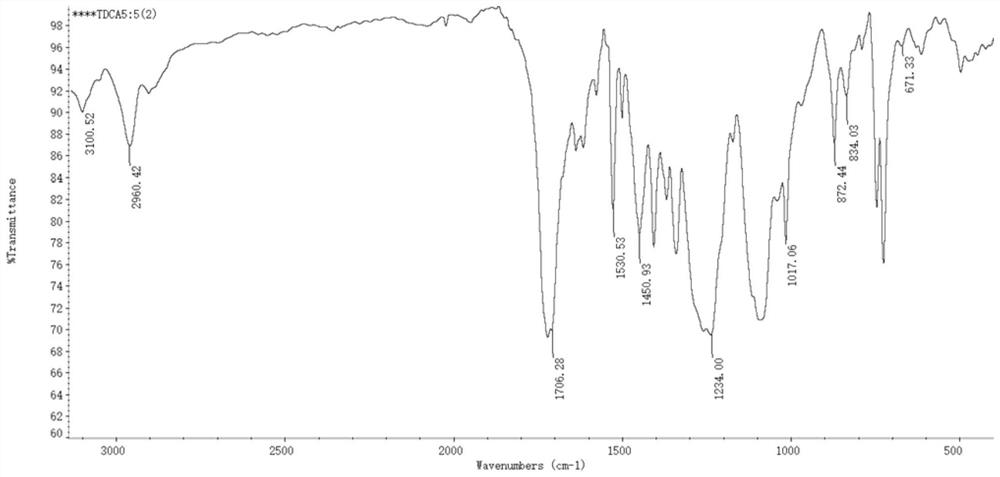

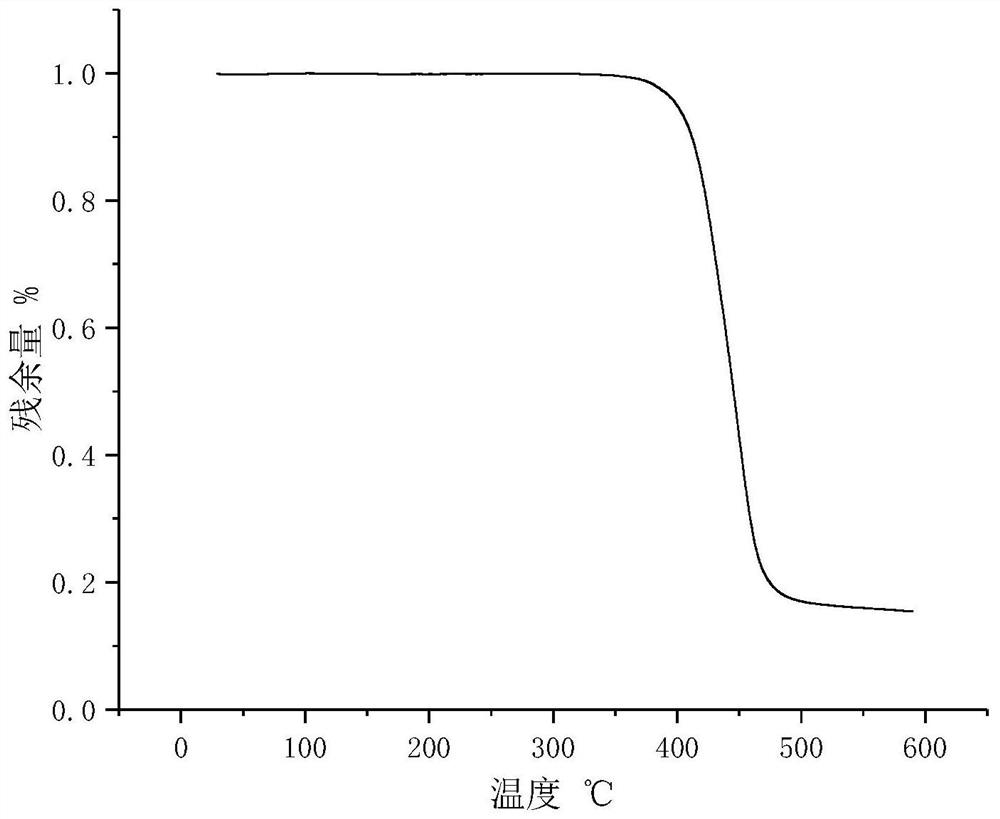

[0089] Characterization:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com