Crushed stone spreading device for pavement construction

A spreading device and gravel technology, which is applied in road repair, roads, roads, etc., can solve the problems of small thickness of stone chips scattered by the screw spreader, leakage of stone materials, and influence on construction quality, so as to improve the compactness and stability of the overall structure Good performance, small gaps, and efficient construction of pavement construction gravel spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

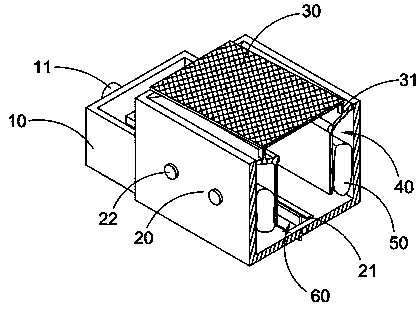

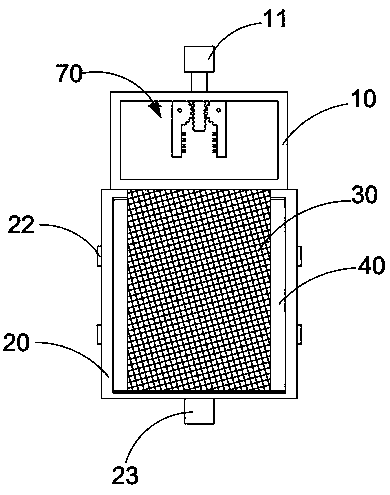

[0028] see Figure 1-7 As shown, the gravel spreading device is built on the road surface, including:

[0029] Spreading box 20, the box bottom surface of spreading box 20 has a material spreading groove 21,

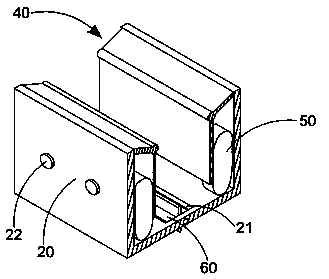

[0030] Rotating assembly 60, rotating assembly 60 is installed on the wall surface of two grooves of material spreading tank 21, and rotating assembly 60 is used for realizing the opening or closing of material spreading port 21, and

[0031] Hinge 40, hinge 40 comprises the first vane 42 that one end is connected with spreading box 20 box walls, and the other end of first vane 42 is connected with connecting shaft 41, is also connected with rotatable second vane 43 on the connecting shaft 41,

[0032] Wherein, an air bag 50 is provided between the second blade 43 and the wall of the spreading box 20 . The spreading tank 21 is a rectangular tank body. Two corresponding box walls of the spreading box 20 are connected with symmetrically arranged hinges 40 .

[0033]The...

Embodiment 2

[0042] see Figure 1-7 As shown, the pavement trimmed gravel spreading device includes the spreading box 20 as a rectangular box shape, and the upper end surface of the spreading box 20 is opened, and the air bag 50 is connected with the air pump through the air pipe, which is not shown in the figure, but should be the Those skilled in the art understand that the filling / deflation technology of the airbag 50 will not be described too much here, the airbag 50 is placed between the second blade 43 and the box wall of the spreading box 20, the screen 30 is a metal mesh plate, and its net The size of the hole is selected according to the requirements of actual gravel spreading. The number of partitions 61 on the support shaft body 62 is preferably 4. The partitions 61 surround the support shaft body 61 with an interval angle of 90°. The gravel box 10 is a rectangular box. body, the upper end is opened, so that gravel falls into the gravel box 10, and the briquetting block 74 is a ...

Embodiment 3

[0045] When the gravel spreading device for road construction of the present invention is actually used: the device of the present invention is installed on a movable device, such as a car or a trolley, and there is no shelter under the bottom of the specific spreading box 20, so as to meet the requirements of spreading. Gravel requirement, the box walls on both sides of the spreading box 20 are connected and fixed with the movable equipment. During the gravel spreading process, the motor 23 is started to control the rotation of the rotating assembly 60 to realize the opening and closing of the spreading trough 21, and then the spreading The gravel in the box 20 is scattered downward, and the gravel entering the spreading box 20 needs to be filtered by the screen 30. If the gravel screened by the screen 30 is too large, the gravel will slide down to the gravel box along the screen 30. 10, the crushed stone component 70 crushes the crushed stones with too large particle size and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com