Movable truss and supporting aluminum mold system and construction method thereof

A truss system and truss technology, applied in the field of movable truss and supporting aluminum formwork system and its construction, can solve the problems of inconvenient formwork axial support and fixation, and achieve the effects of controlling construction quality, convenient construction, and many times of repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

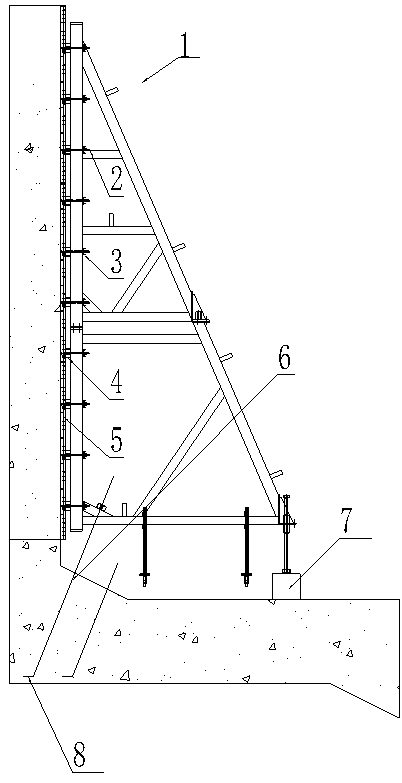

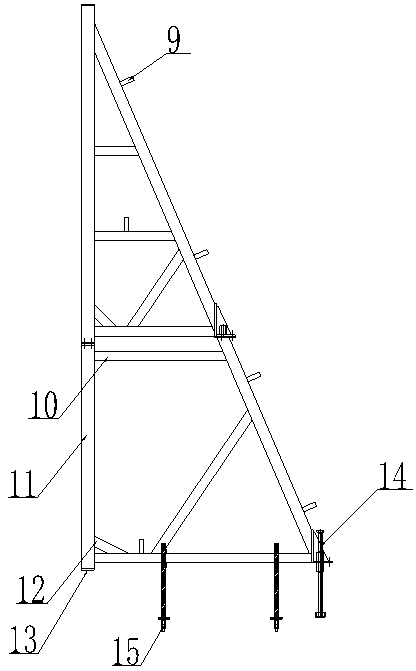

[0036] like figure 1 , figure 2 As shown, a movable truss and supporting aluminum formwork system, including a formwork system, a movable truss system, a connection system and a fastening system, the formwork system includes several aluminum alloy formwork bodies 5, the movable truss system and the aluminum formwork through the connection system The alloy formwork body 5 is connected, and the fastening system includes cable-stayed ground anchor bolts 6 welded to the steel bars 8 of the bottom plate.

[0037] The movable truss system is formed by connecting multiple movable trusses 1 through horizontal tie rods or back corrugations.

[0038] The movable truss 1 is fixed at right angles by pre-embedded cable-stayed ground anchor bolts 6. The connection system includes movable screw 2, back corrugated 4 and mountain nut 3. The movable screw 2 is a pipe or L-shaped, and the movable screw connects the movable truss 1 and The aluminum alloy formwork body 5 and the back flute 4 ar...

Embodiment 2

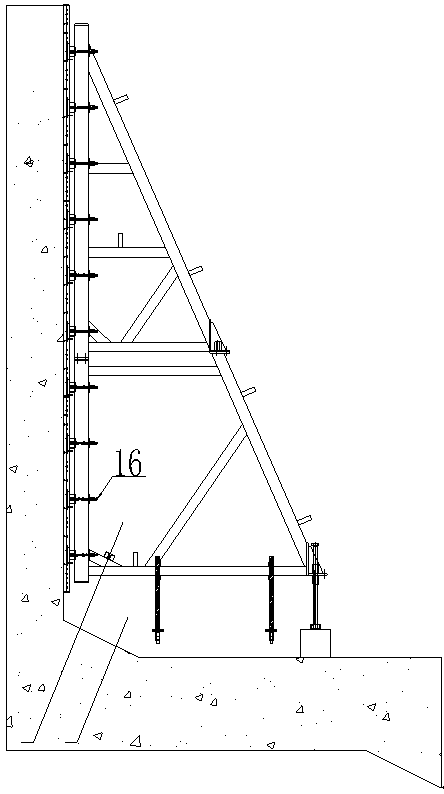

[0059] like image 3 As shown, the difference between this and Embodiment 1 lies in step h. In Embodiment 2, the movable truss 1 is fixed to the back corrugated 4 through the clamp rod 16 to achieve the connection between the movable truss 1 and the formwork system.

[0060] The aluminum alloy formwork of this system is a general model with a high standard rate, and the formwork can be used universally during use. There is less construction waste on site, which reduces the iron nails and other sundries needed for wooden formwork, making the construction site cleaner and tidy. Compared with the steel mold, it reduces the dependence on machinery and saves the cost of steel mold derusting. The recycling value is high, and the aluminum alloy formwork has been refurbished after recycling and can be reused. The construction period is short, the number of repeated uses is high, the average use cost is low, the construction is convenient, and the efficiency is high. It can control t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com