Control system and method for equal pressure difference flow increasing

A technology of flow control system and equal pressure difference, which is applied in the field of pressure difference increase flow control system, can solve the problems of affecting water supply and heating efficiency, high power consumption and heat consumption, and affecting heating efficiency, so as to improve water supply or heating efficiency. Thermal efficiency, reducing power consumption, and solving the effect of hydraulic imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following description illustrates specific embodiments of the invention sufficiently to enable those skilled in the art to practice and reproduce it.

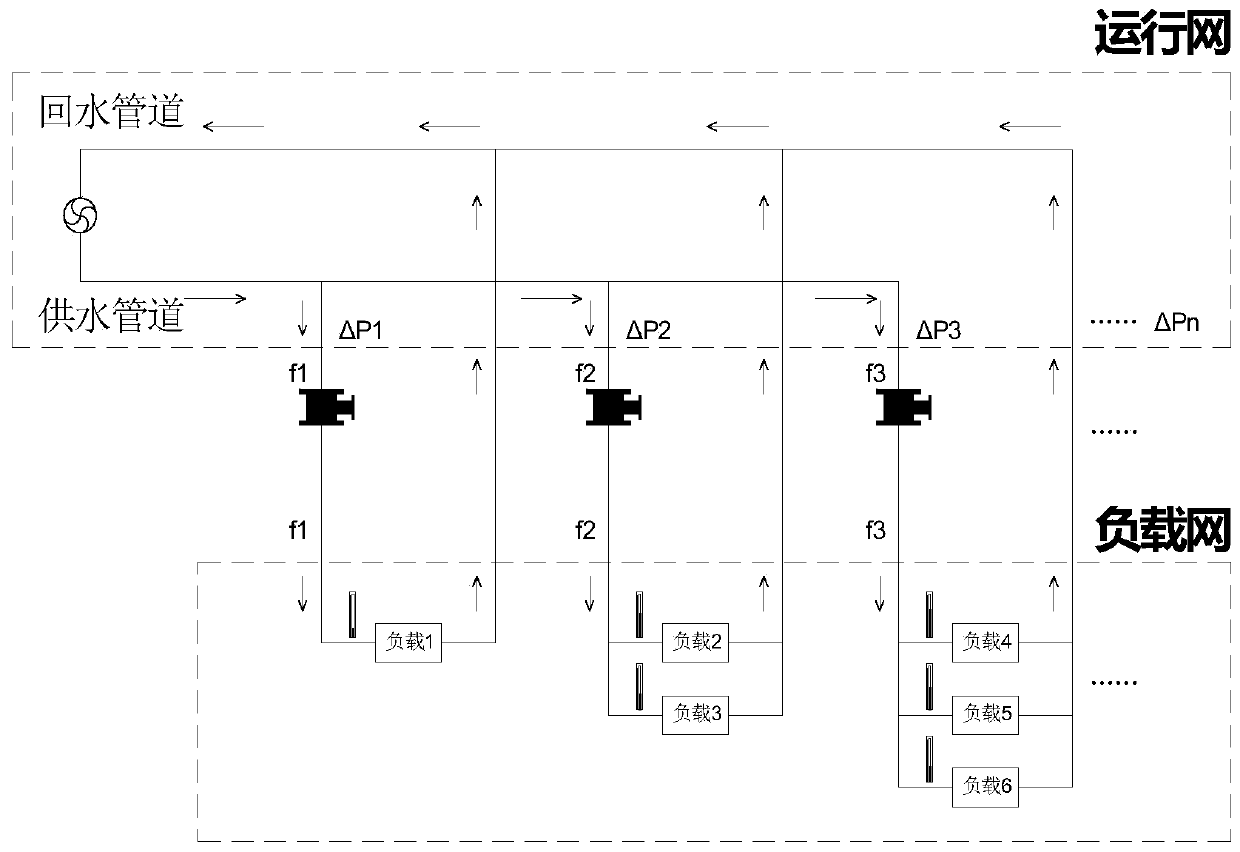

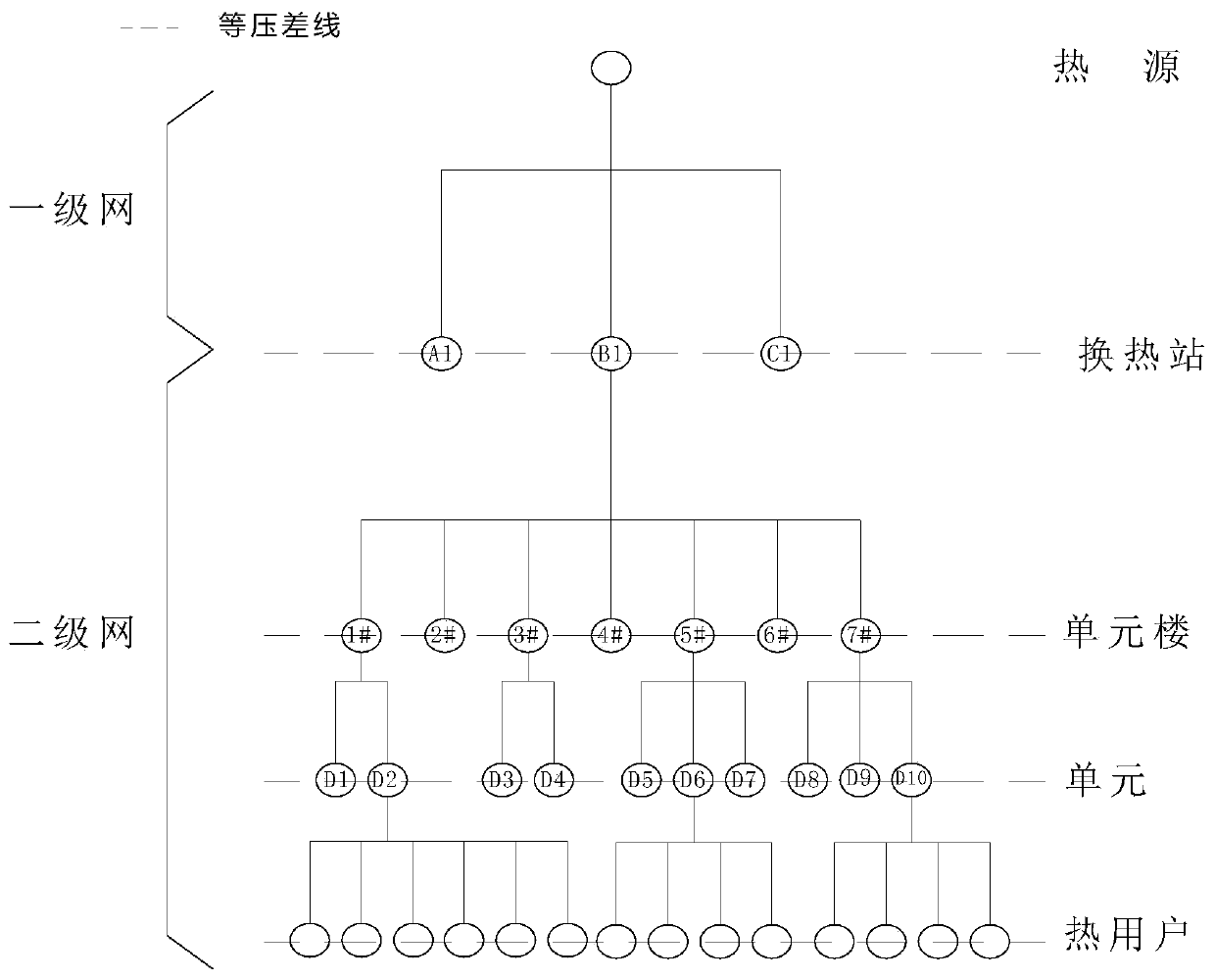

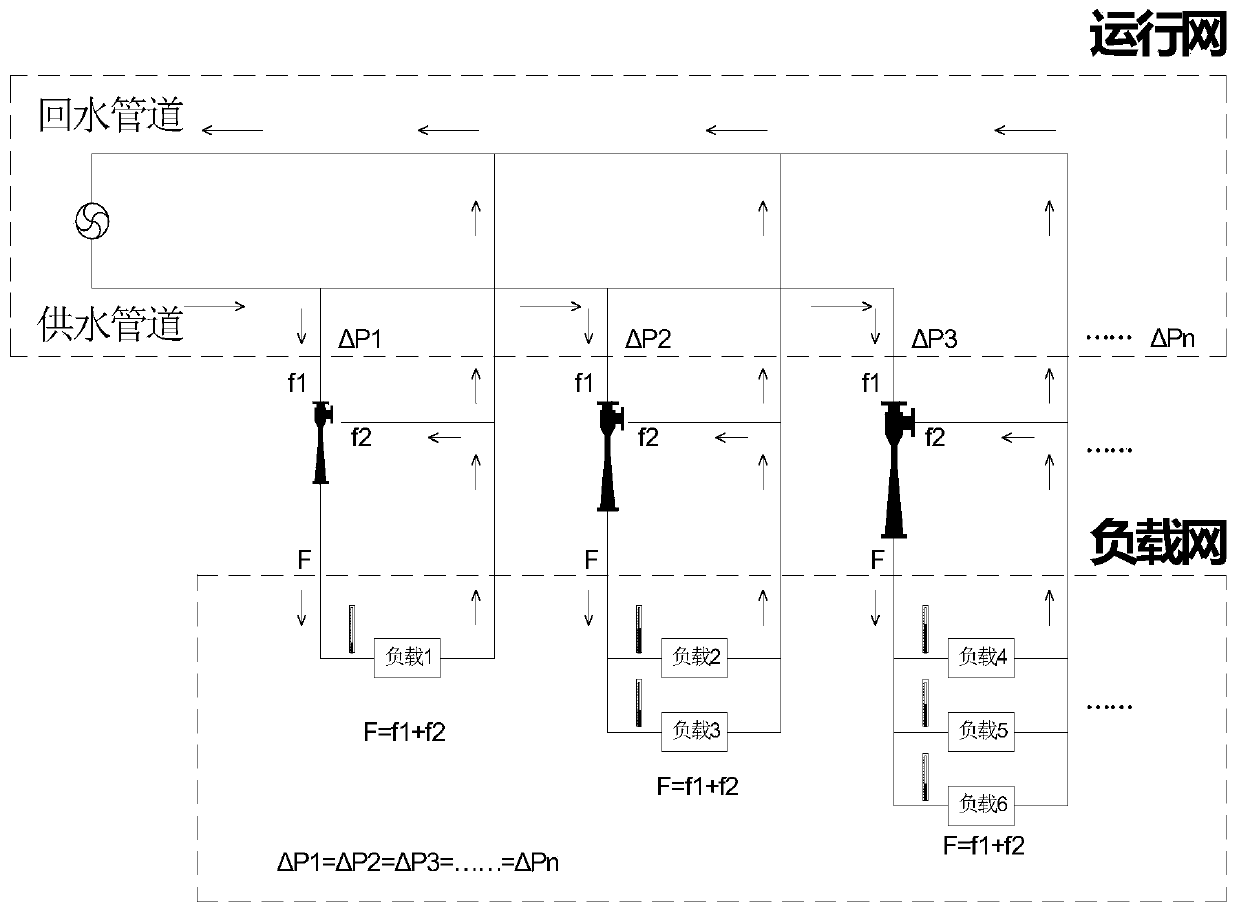

[0027] Such as image 3 Shown is the working principle diagram of the pipe network system in the present invention; as Figure 4 Shown is the distribution diagram of the pipe network system in the present invention; as Figure 5 Shown is a schematic structural view of the Venturi jet pump of the present invention.

[0028] The pipe network system is divided into operation network and load network. In the present invention, a Venturi jet pump is installed at the front end of the load network of the pipe network system. The Venturi jet pump is a device that connects the operating network and the load network.

[0029] The inlet 1 of the Venturi jet pump is connected to the outlet pipeline of the running net, the outlet 2 of the Venturi jet pump is connected to the water inlet pipeline of the load net, and the sucti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com