Lubricating flow control system for wet type double clutches

A wet double clutch, flow control technology, applied in gear lubrication/cooling, transmission parts, belts/chains/gears, etc., can solve problems such as friction element surface ablation, clutch failure, affecting driving safety, etc., to achieve calculation precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

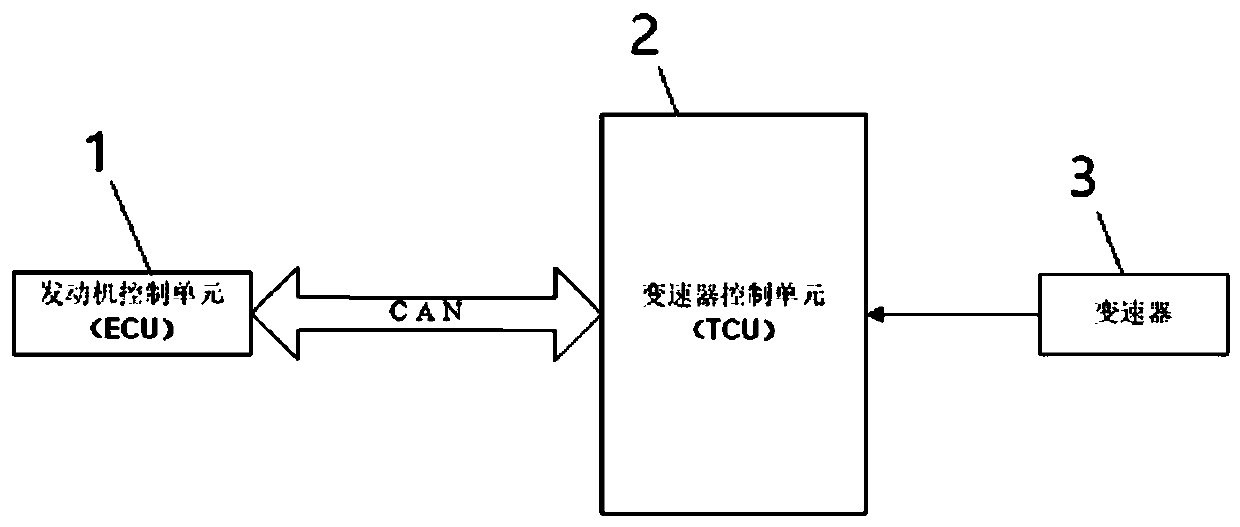

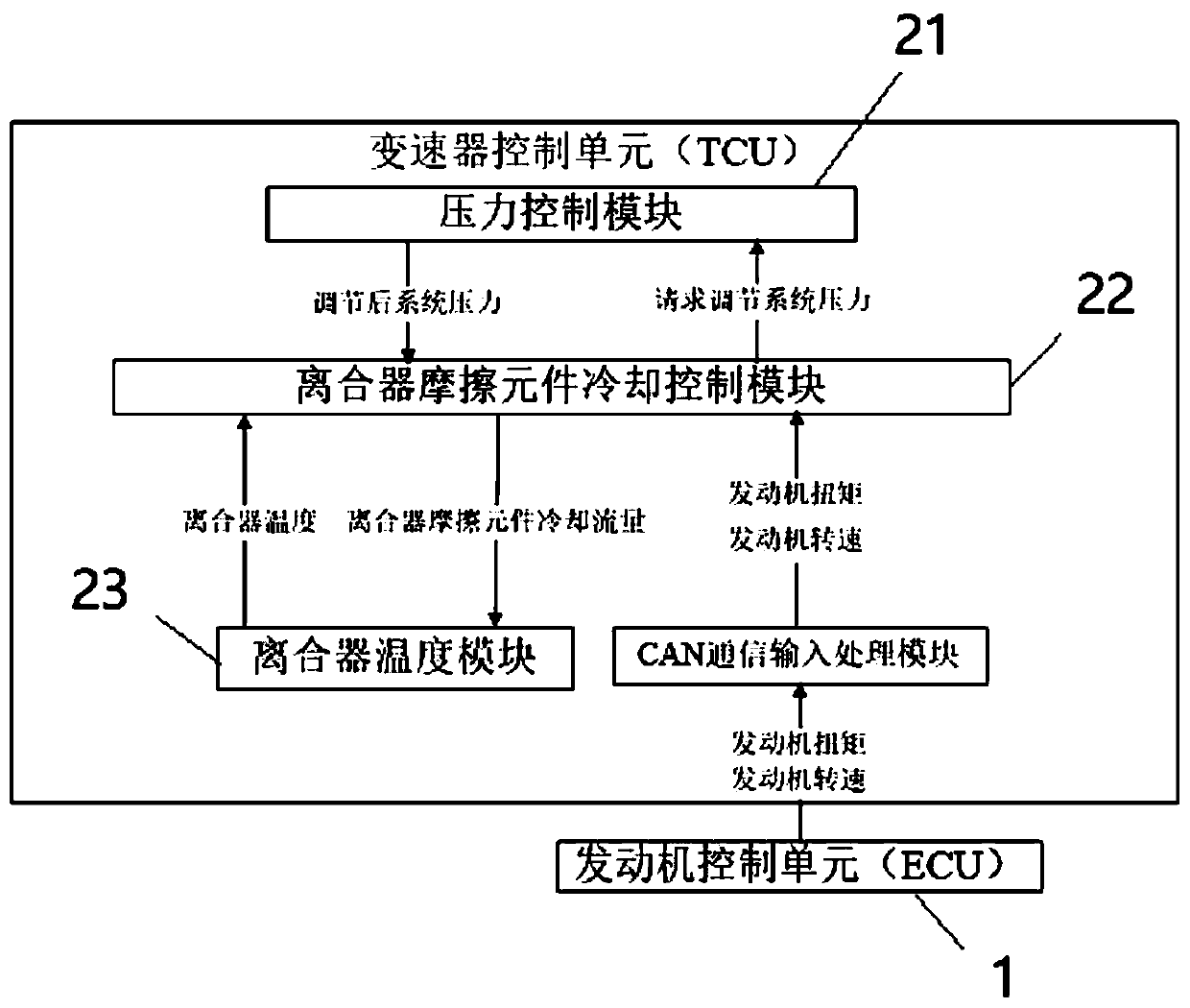

[0026] Such as figure 1 , figure 2 As shown, the wet dual clutch lubrication flow control system includes a transmission control unit 2 and an engine control unit 1 . Wherein, the transmission control unit is used to control the transmission 3, and communicates with the engine control unit 1 through a CAN line. The transmission control unit includes: a clutch friction element cooling control module 22 , a clutch temperature module 23 and a pressure control module 21 .

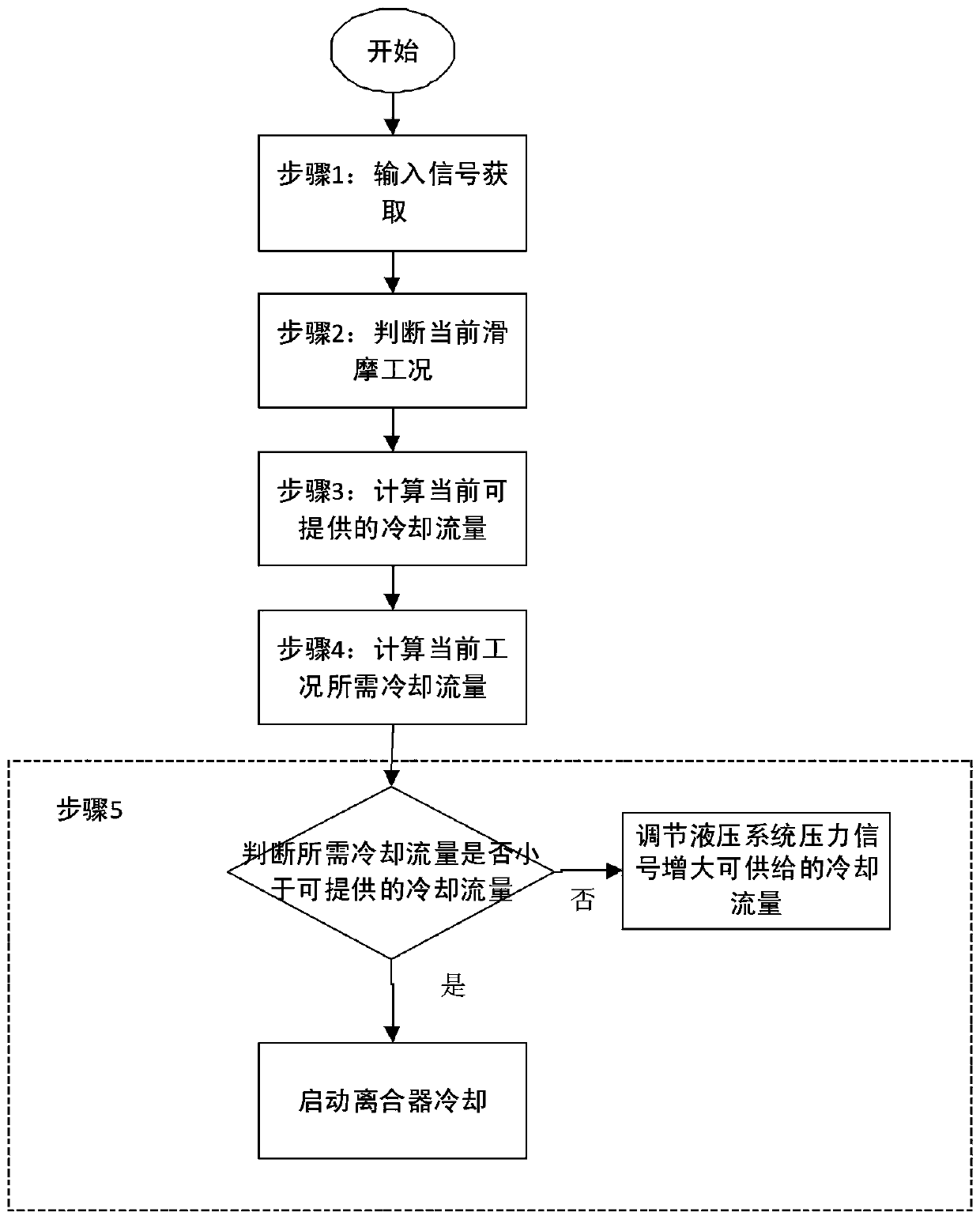

[0027] Such as Figure 2 to Figure 3 As shown, the wet dual clutch lubrication flow control system works as follows:

[0028] 1) The clutch friction element cooling control module 22 obtains the engine torque signal, the engine speed signal and the vehicle speed signal from the engine control unit 1; the clutch friction element cooling control module 22 obtains the heat temperature of the clutch generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com