Impeller dynamic balance de-weight automatic turning device and method

A turning device and impeller technology, applied in the direction of grinding drive device, static/dynamic balance test, measuring device, etc., can solve problems such as deformation and unbalanced quality, difficulty in dynamic balance and weight removal, and hidden dangers of operation safety, etc., to achieve Avoid the rotation of the disc impeller, the effect of de-weighting work is good, and the effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

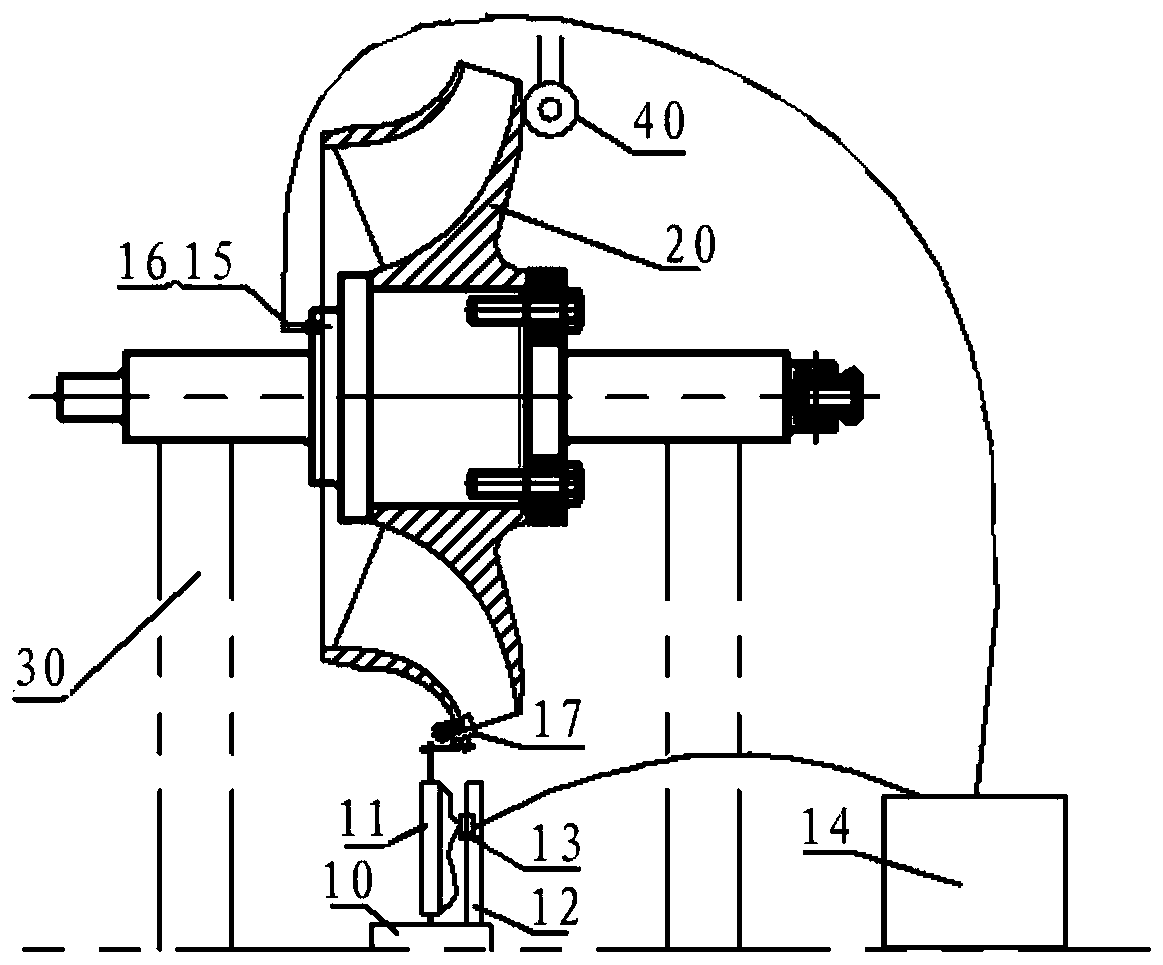

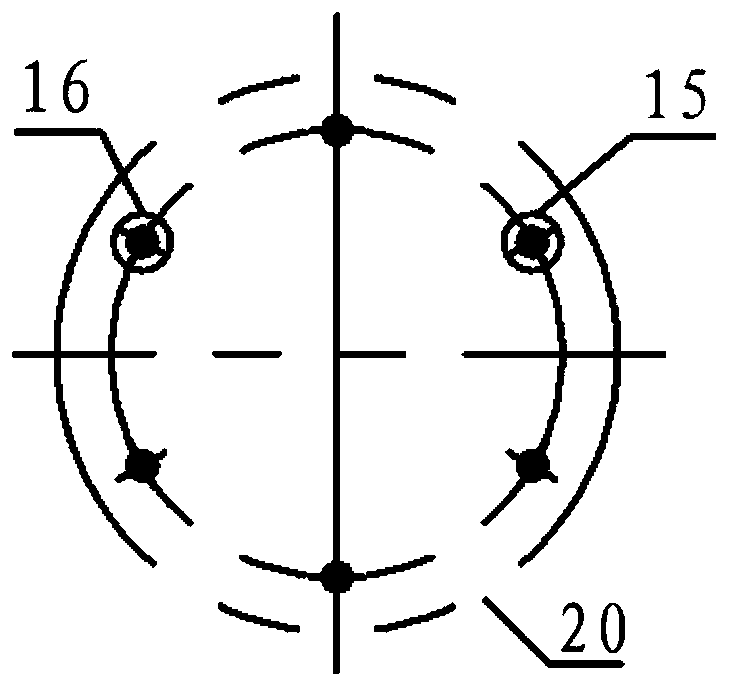

[0019] see figure 1 , an impeller dynamic balance de-weighting automatic turning device provided in an embodiment of the present invention includes a base 10, a cylinder 11, a cylinder bracket 12, a universal clamp 17, an electric control device 14, a first non-contact probe 15, a second non-contact probe Contact probe 16, and probe support (probe support figure 1 not shown). Wherein, the impeller 20 is fixed on the dynamic balancing machine 30 through the axles on both sides, the base 10 is fixedly arranged on the workbench of the dynamic balancing machine 30, the universal clamp 17 is fixed at the outlet position of the impeller 20, and one end of the cylinder 11 is hinged on the base 10, the other end is connected with Vientiane fixture 17 through hinges, and the two ends of cylinder 11 are respectively hinged with base 10 and Vientiane fixture 17, which can ensure that cylinder 11 swings freely during motion. At the same time, in order to avoid cylinder 11 topple over, cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com