Shell testing method

A test method and shell technology, which is applied in vibration test, impact test, machine/structural component test, etc., can solve the problems of poor quality of the shell to be tested, delay of product production progress, low test efficiency, etc., and improve cracking Defects, avoid taking too much time, reduce the effect of repeated testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

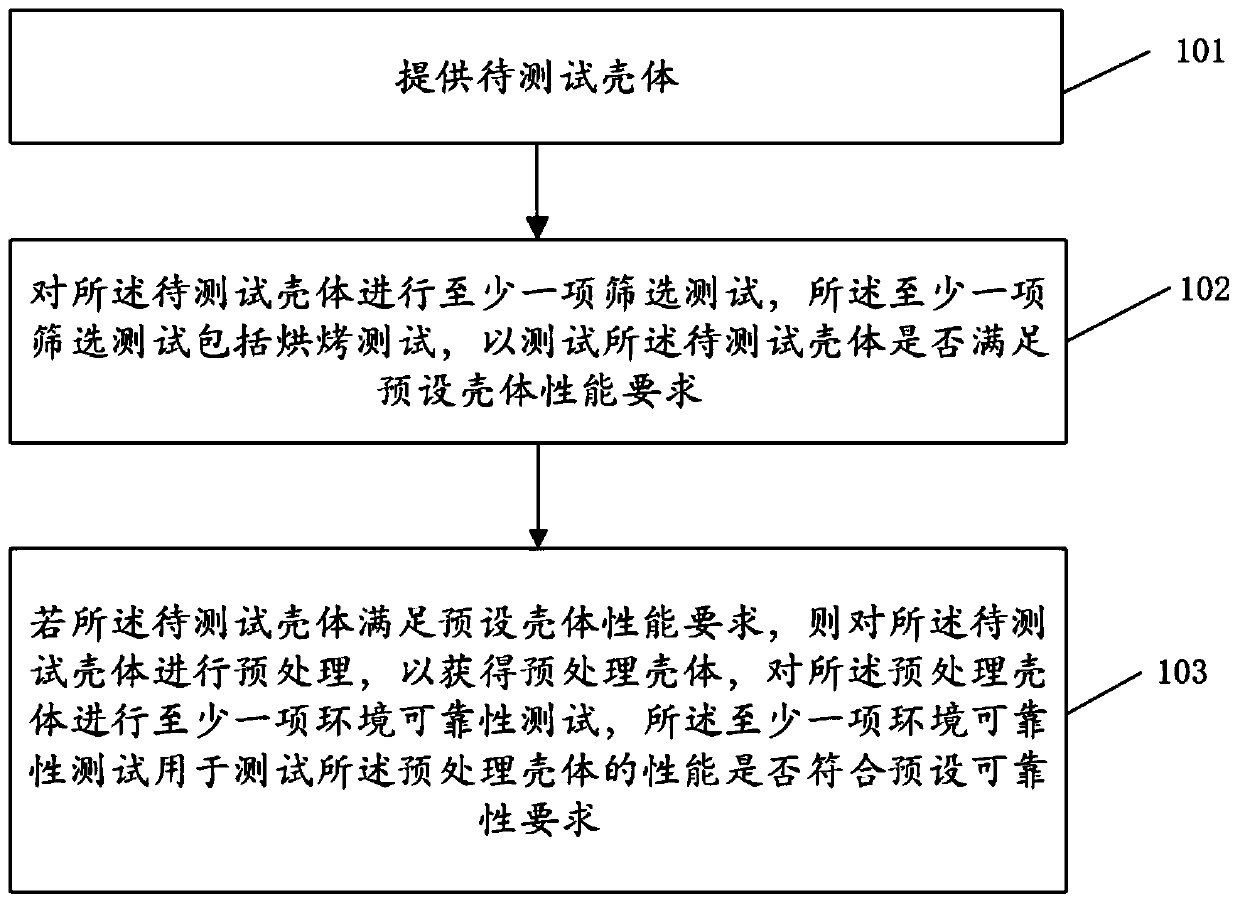

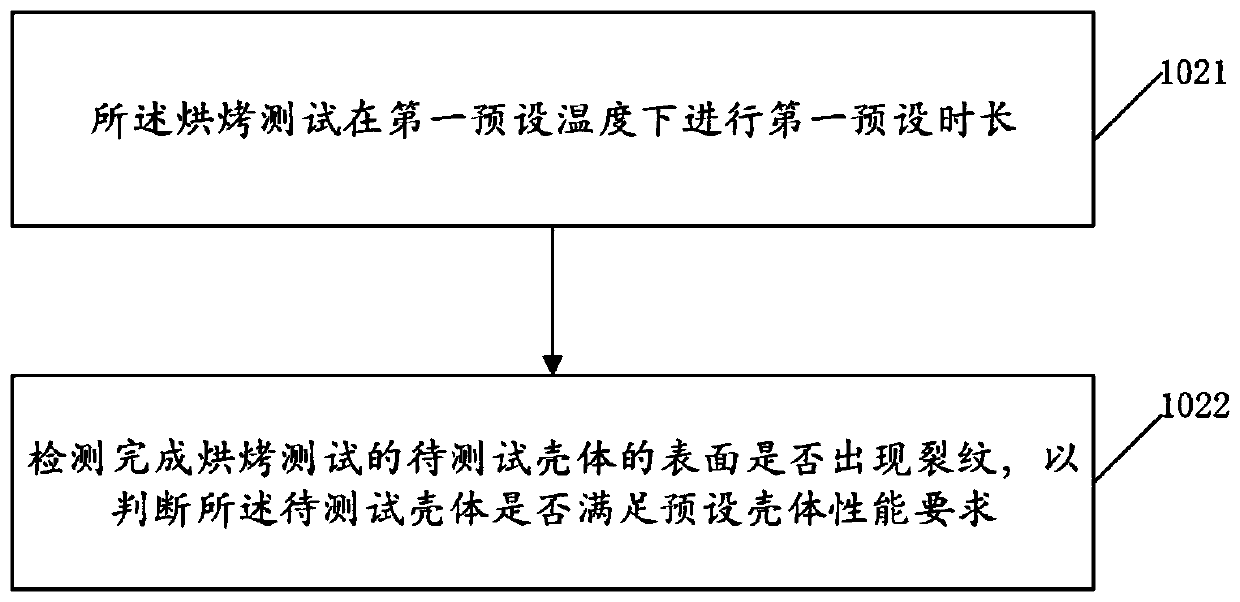

[0016] see figure 1 , the embodiment of the present application provides a casing testing method, the casing testing method includes steps 101 to 105:

[0017] 101: providing a shell to be tested.

[0018] In step 101, the casing to be tested is a battery cover structure. The casing to be tested can be applied to an electronic device, and the electronic device can be a smart phone, a smart watch, a tablet computer, a notebook computer, or a wearable smart device. In other implementation manners, the casing to be tested is not limited to the above-mentioned battery cover, and can be set by itself according to actual needs.

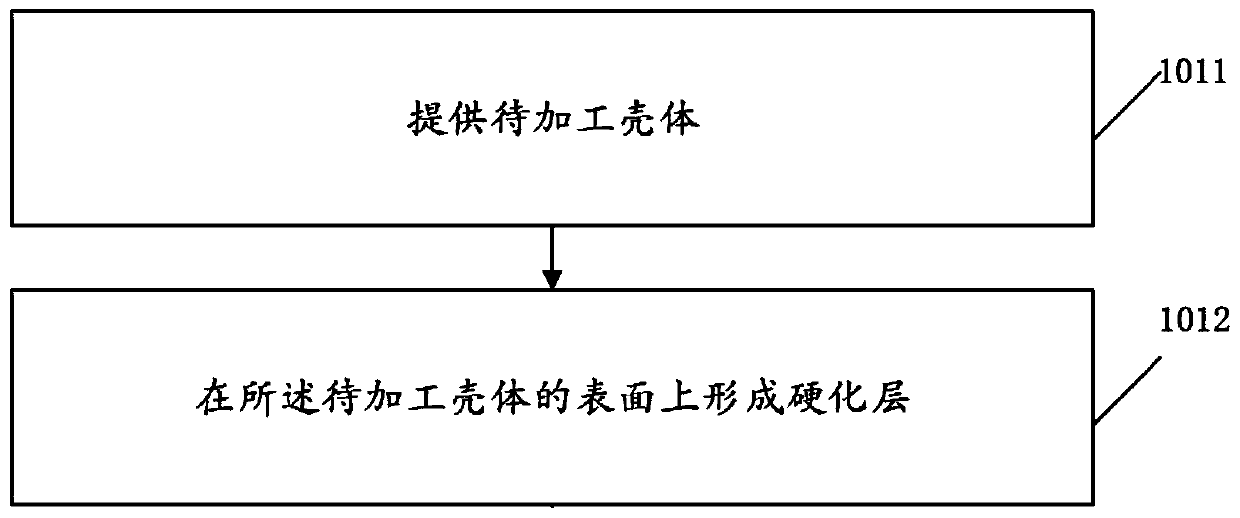

[0019] The casing to be tested is a plastic casing, and the specific material of the casing to be tested is not limited. The casing to be tested may be a transparent casing or a non-transparent casing. A hardened layer is provided on the surface of the casing to be tested, and the hardened layer can increase the surface hardness of the casing to be test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com