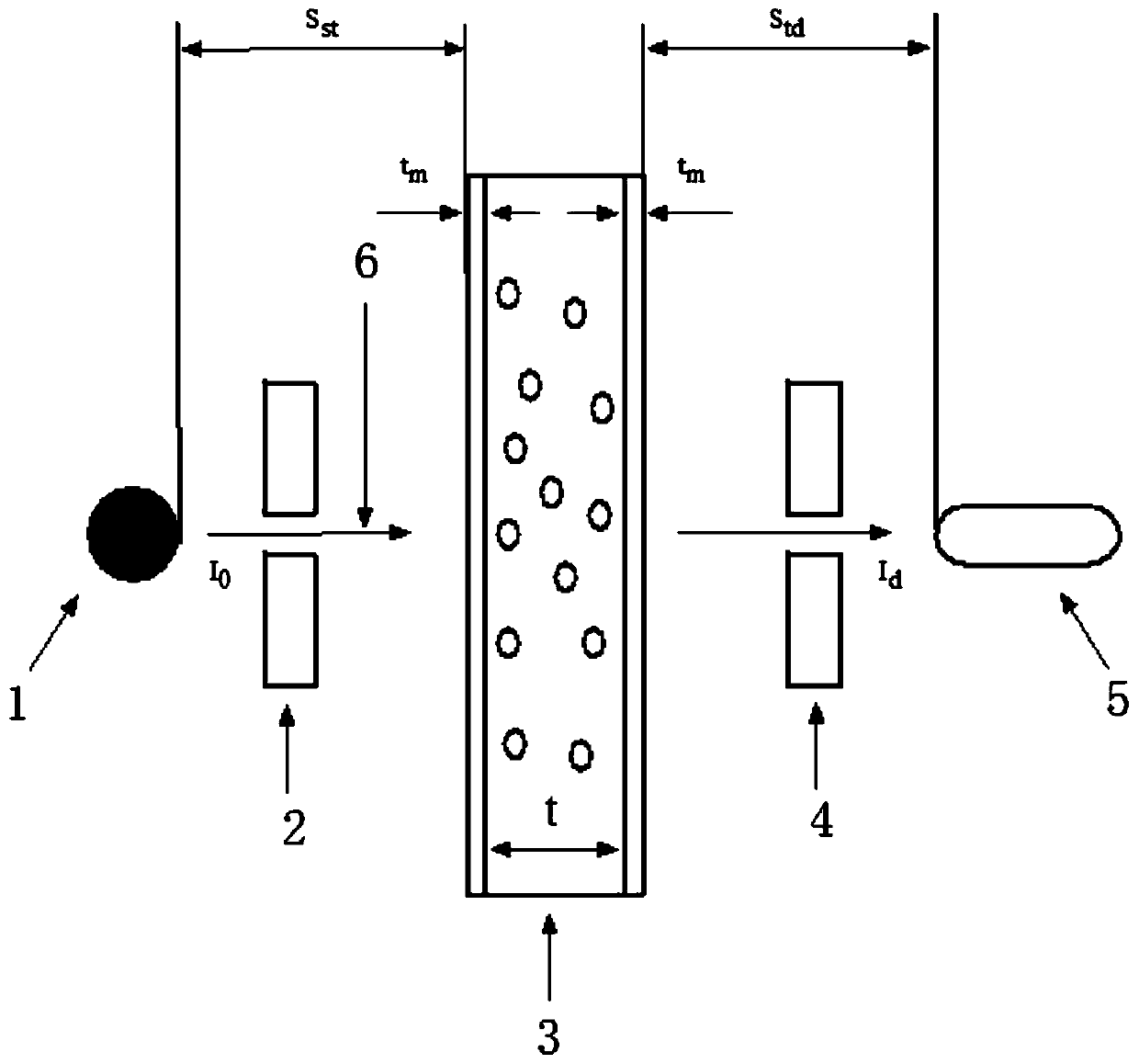

Dryness measurement system and method of gas-liquid two-phase fluid under high temperature and high pressure

A high-temperature, high-pressure, measurement system technology, applied in the direction of material analysis using radiation, can solve the problems of decreased accuracy and inability to measure, and achieve the effect of simple structure and simple measurement of dryness of two-phase fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

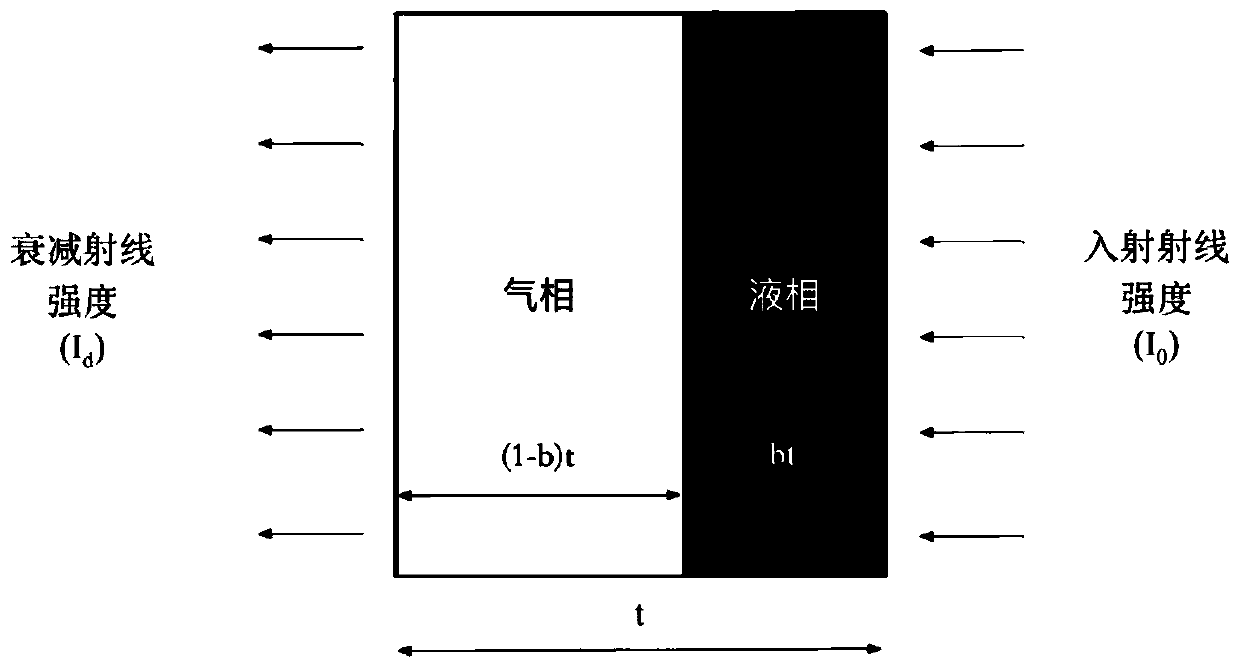

[0053] According to the knowledge of gas-liquid two-phase fluid dynamics, there is a certain functional relationship between the two-phase coherence degree and the two-phase volumetric gas fraction, and the specific expression is

[0054]

[0055] In the formula:

[0056] x—gas-liquid two-phase fluid dryness;

[0057] β—gas-liquid two-phase fluid volumetric gas fraction;

[0058] ρ L — liquid phase density;

[0059] ρ G - gas phase density.

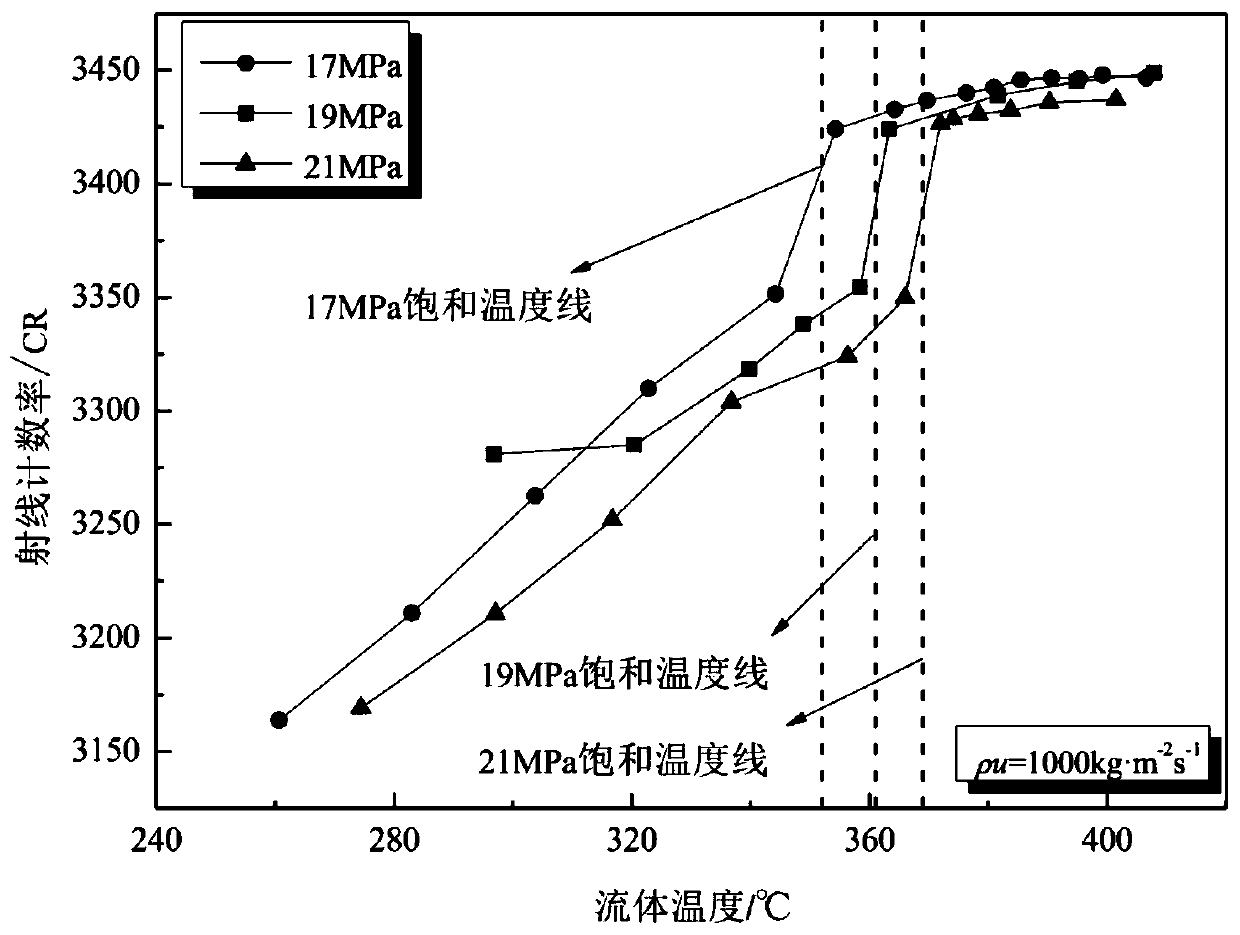

[0060] Substituting the measured volume gas fraction β into the above formula, the dryness value of the two-phase fluid can be obtained. Although there are many measurement methods for volumetric gas content, most of them focus on non-heating or low temperature conditions. There is still no effective method for the measurement of this parameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com