Process for selective ethylene oligomerization with antifouling components

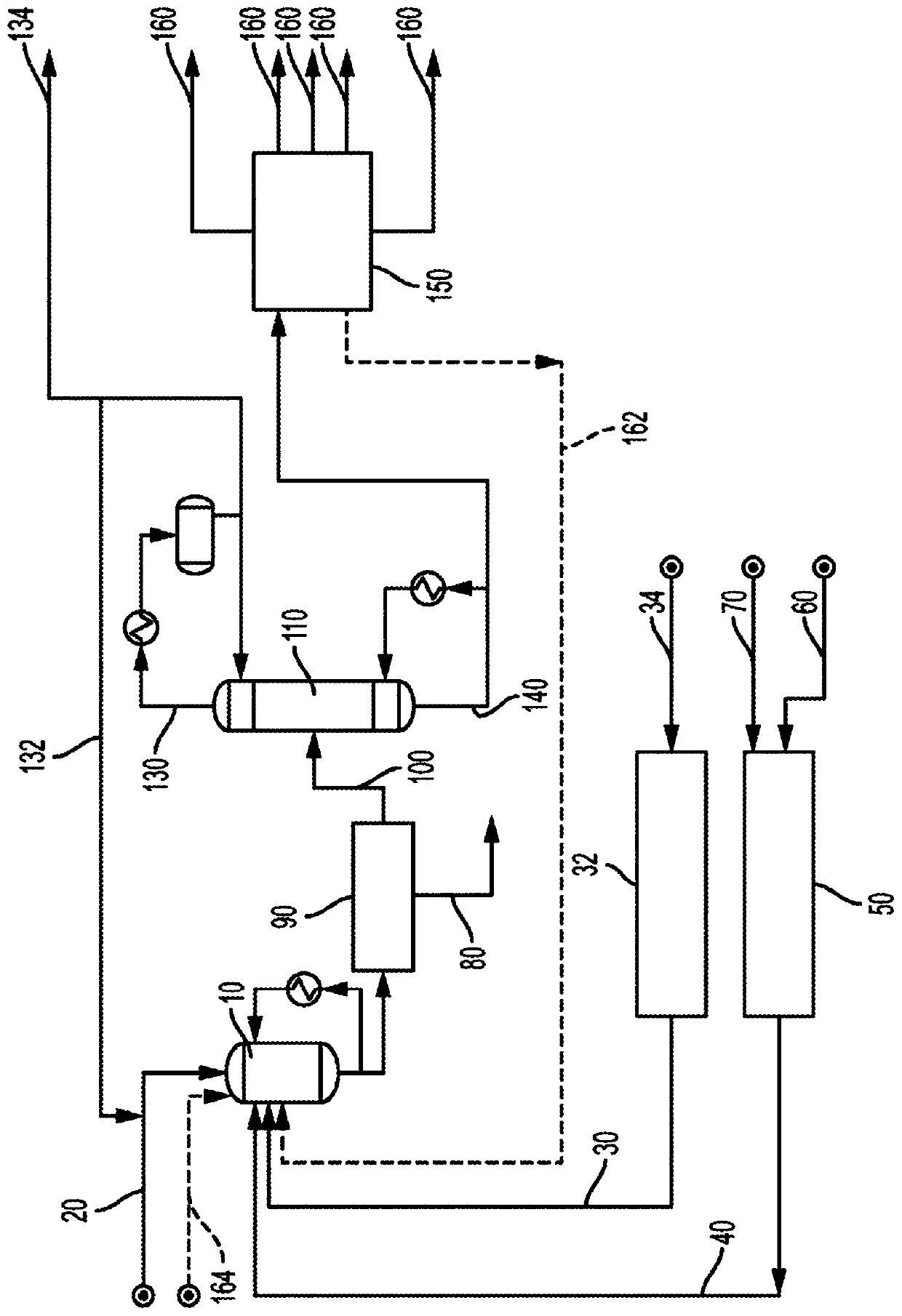

A selective, anti-fouling technology, applied in chemical instruments and methods, physical/chemical process catalysts, bulk chemical production, etc., can solve problems such as runaway polymerization, loss of cooling capacity, process shutdown, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0072] Various embodiments of the antifouling catalyst system and performance of the antifouling compound injection system will be additionally illustrated by the following examples. The examples are illustrative in nature and should not be construed as limiting the subject matter of the present disclosure.

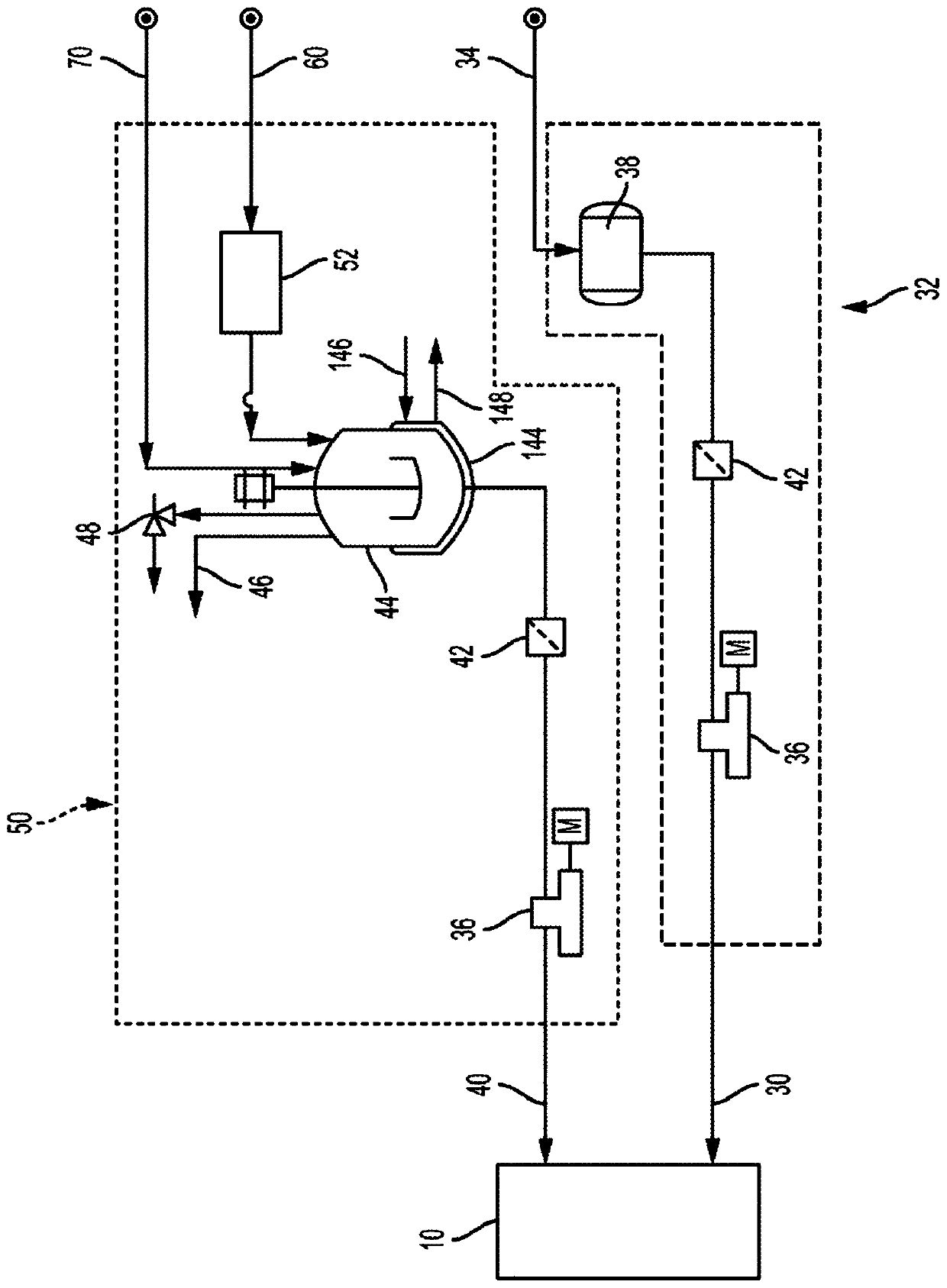

[0073] To evaluate the antifouling effect of the antifouling catalyst system and method, an ethylene dimerization reaction was performed and evaluated. A number of sample antifouling catalyst systems were formulated and tested according to the methods of the present disclosure. A method of selective ethylene dimerization with an antifouling component and an associated antifouling compound injection system was compared to a baseline comparison system. Specifically, using an antifouling compound injection system, the cocatalyst and antifouling agent are premixed in an antifouling compound mixing vessel and then injected into the process reactor as a separate stream from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com