Cotton picker pneumatic cleaning system and cotton picker

A cotton picker and wind power technology, which is applied in the cotton picker wind power removal system and the field of cotton pickers, can solve problems such as cyclone filter and dust removal net blockage, achieve the goal of avoiding blockage, simplifying the dust removal structure, and improving the removal effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

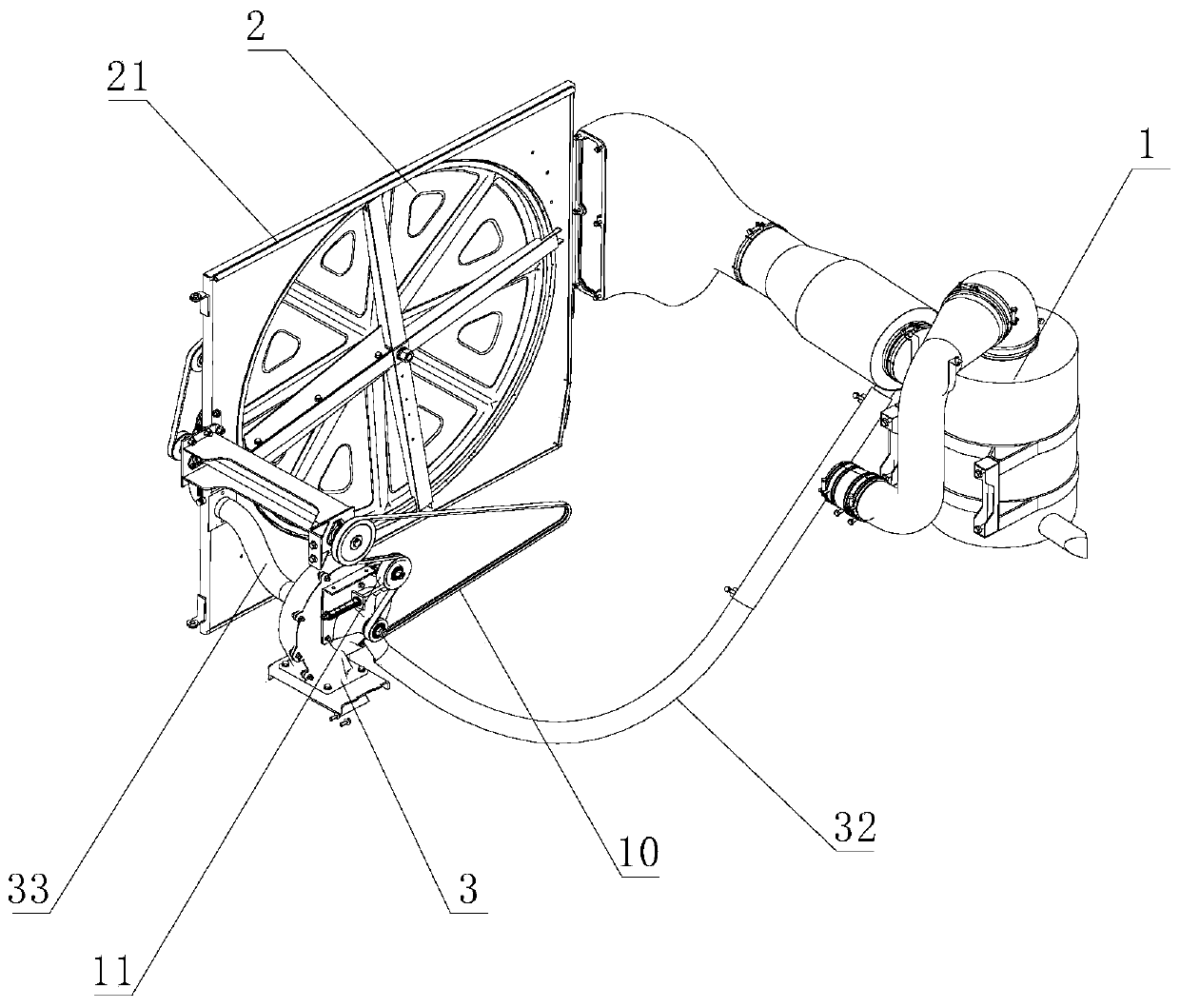

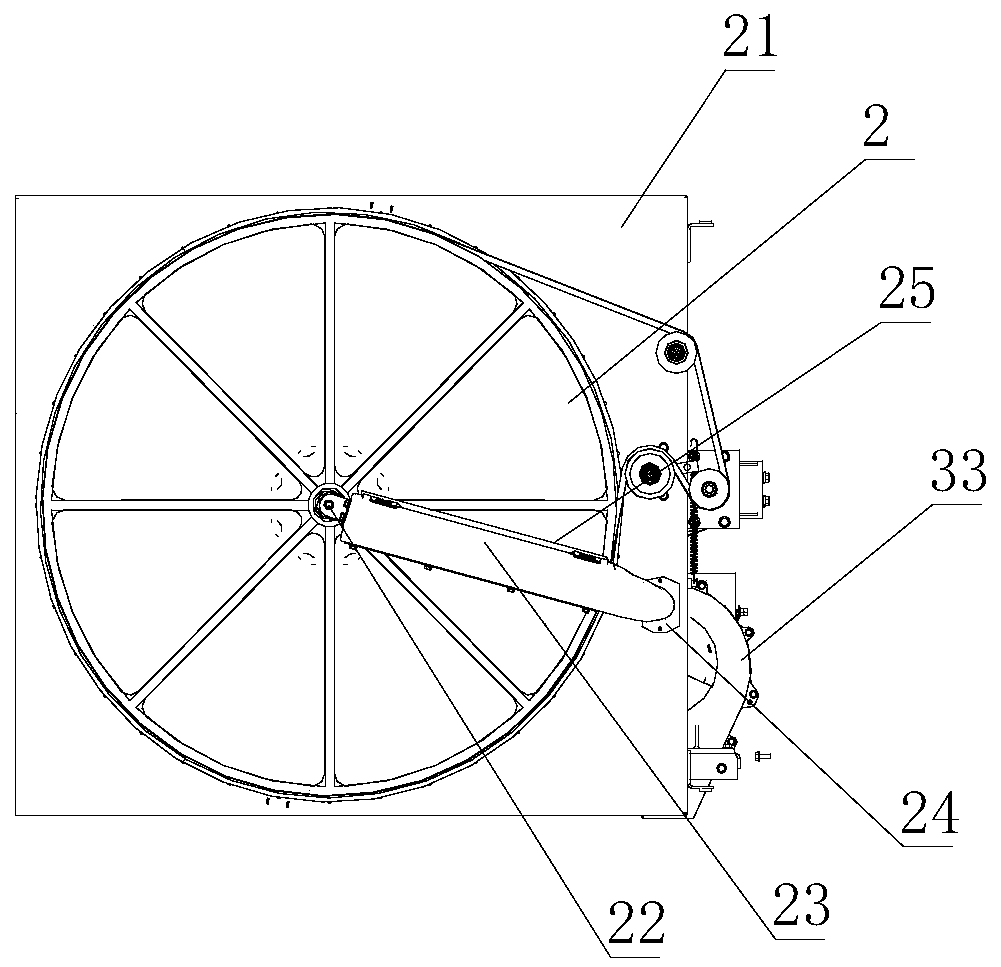

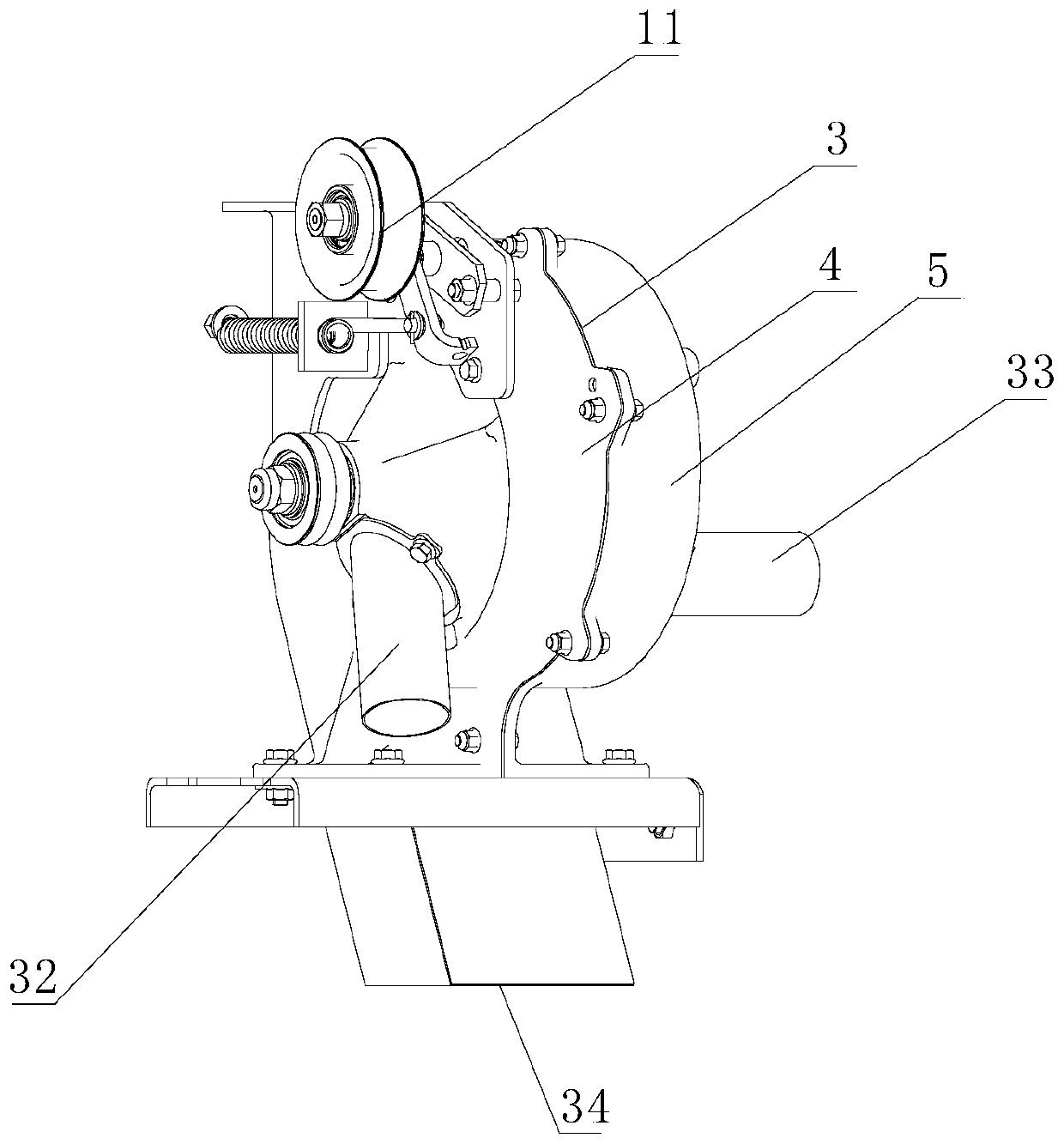

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a cotton picker wind power removal system includes a cyclone filter 1, a removal net 2 and a centrifugal fan 3, the centrifugal fan 3 includes a first cavity 30 and a second cavity 31, and the first cavity 30 is not equal to the pressure in the second cavity 31, the first cavity 30 is connected with the first air duct 32 connected with the cyclone filter 1, the second cavity 31 is connected with the impurity removal The second air pipe 33 connected to the net 2, the dust in the cyclone filter 1 enters the first cavity 30 through the first air pipe 32, and the dust on the impurity removal net 2 enters the first air pipe 33 through the second air pipe 33. In the second cavity 31, a miscellaneous outlet 34 is also provided between the first cavity 30 and the second cavity 31, and the dust on the cyclone filter 1 is transferred to the second centrifugal fan 3 through the first air pipe 32. One ca...

Embodiment 2

[0038] A cotton picker, including a body, on which the above-mentioned cotton picker wind-force impurity removal system is installed, two different wind forces are generated due to the different pressures in the first cavity and the second cavity of the centrifugal fan, thereby Realized that the centrifugal fan simultaneously removes the impurity net and the cyclone filter, and simplifies the structure of the whole cotton picker.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com