Camera with electrostatic dust removal function

An electrostatic dust removal and camera technology, which is applied in the direction of cameras, electrostatic cleaning, camera body, etc., can solve the problems of aggravating lens wear, affecting lens imaging, and spending more time, so as to improve dust removal efficiency and simple operation method , the effect of shortening the cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

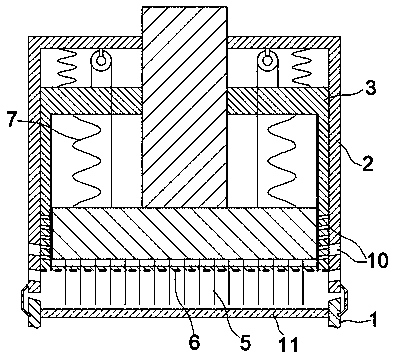

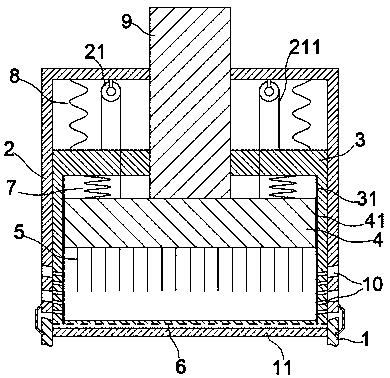

[0022] exist figure 1 , figure 2 In the shown embodiment, the electrostatic dust removal camera includes a camera body, and a lens cover is detachably arranged on the lens 1 of the body;

[0023] The lens cover includes a cover body 2 that can be matched with the lens 1, and the cover body 2 and the lens 1 can be matched through a snap fit, or can be screwed and matched through a screw thread or a screw groove, or matched through magnetic adsorption; A piston frame 3 is slidably arranged in the cover body 2, and the outer wall of the piston frame 3 is in sliding contact with the inner wall of the cover body 2 in close fit;

[0024] A piston plate 4 is slidably arranged inside the piston frame 3, a volatile electronic friction layer 31 is arranged on the inner sidewall of the piston frame 3, and an easy-to-get electronic friction layer 41 is arranged on the outer sidewall of the piston plate 4. The electronic friction layer 41 and the volatile electronic friction layer 31 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com