Method for landfill coverage by using deep-mineralized stale garbage compounding

A landfill, antiquated technology, applied in landfill technology, solid waste removal, restoration of polluted soil, etc., can solve the problems of single function, wasteful operation cost, low permeability coefficient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The invention relates to a method for using deeply mineralized stale waste to compound landfills for covering, in which the deeply mineralized stale wastes are respectively used as fillers for daily covering, intermediate covering and closure repair covering of landfills. After sieving the deeply mineralized stale garbage and removing rubber, plastics and aggregates, the fine material under the sieve is humus.

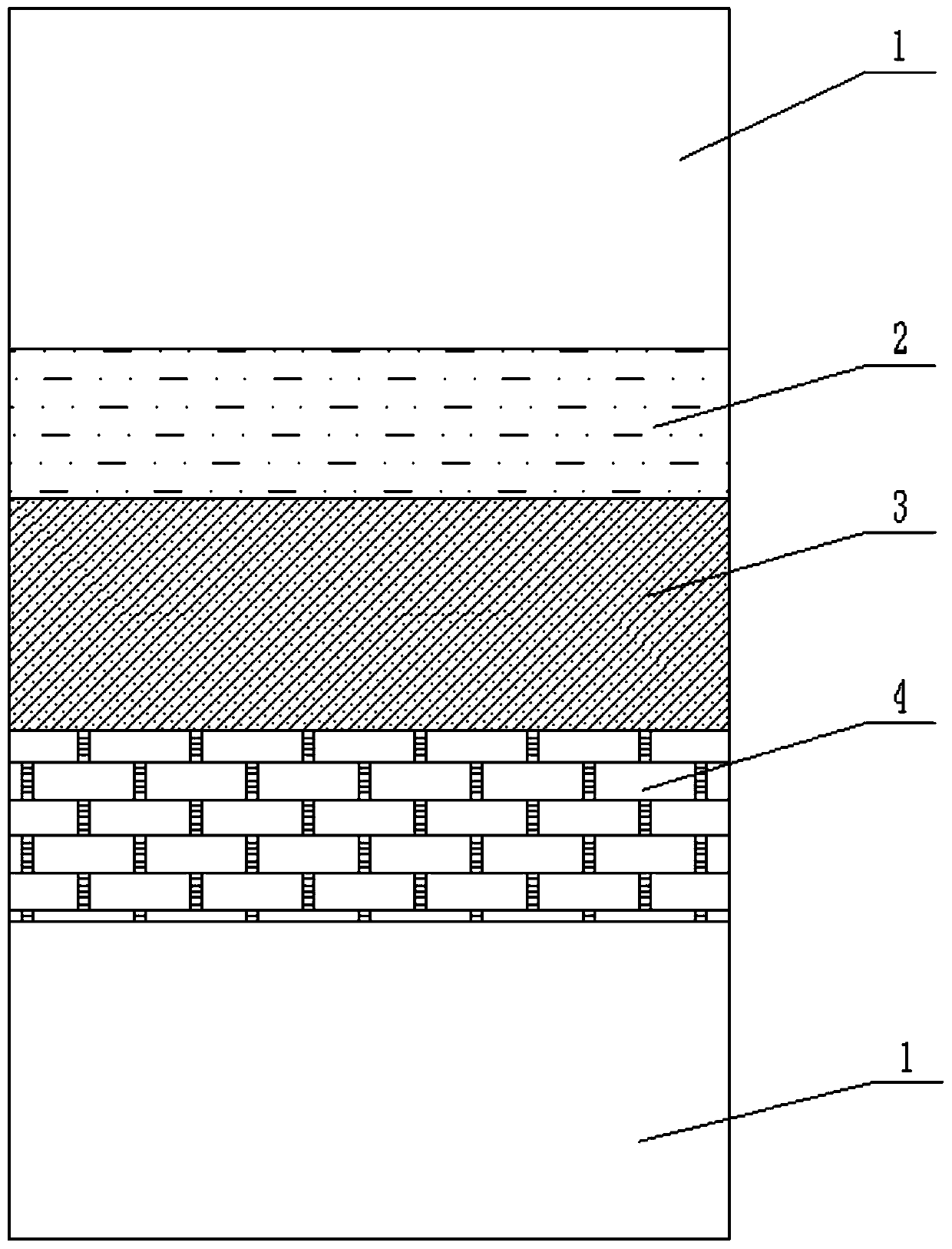

[0027] Such as figure 1 Shown is the daily covering packing layer, between the garbage layer 1, there are protective layer 2, regulating layer 3 and stable layer 4 from top to bottom; the protective layer 1 is a fly ash layer, and the regulating layer 3 is The deep mineralized old garbage humus layer, the stable layer 4 is a composite layer of deep mineralized old garbage humus and lime. The thickness range of the protective layer 2 is 4cm. The thickness range of the adjustment layer 3 is 15cm. The mass composite ratio of deeply mineralized stale garbage humu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com