Dustproof constant force device, control method, mechanical arm, grinding device and robot

A technology of constant force device and mechanical arm, applied in grinding machine tools, manipulators, grinding devices, etc., can solve problems such as damage of constant force output device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

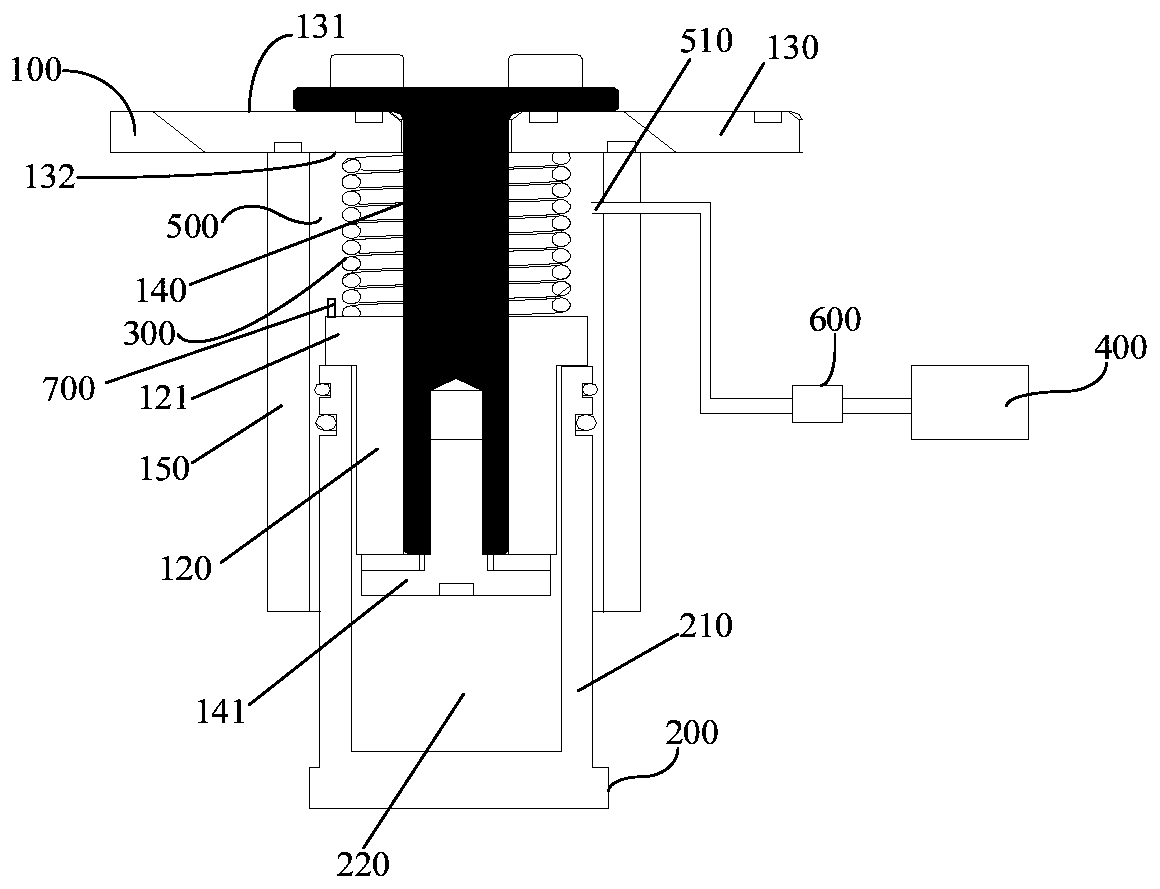

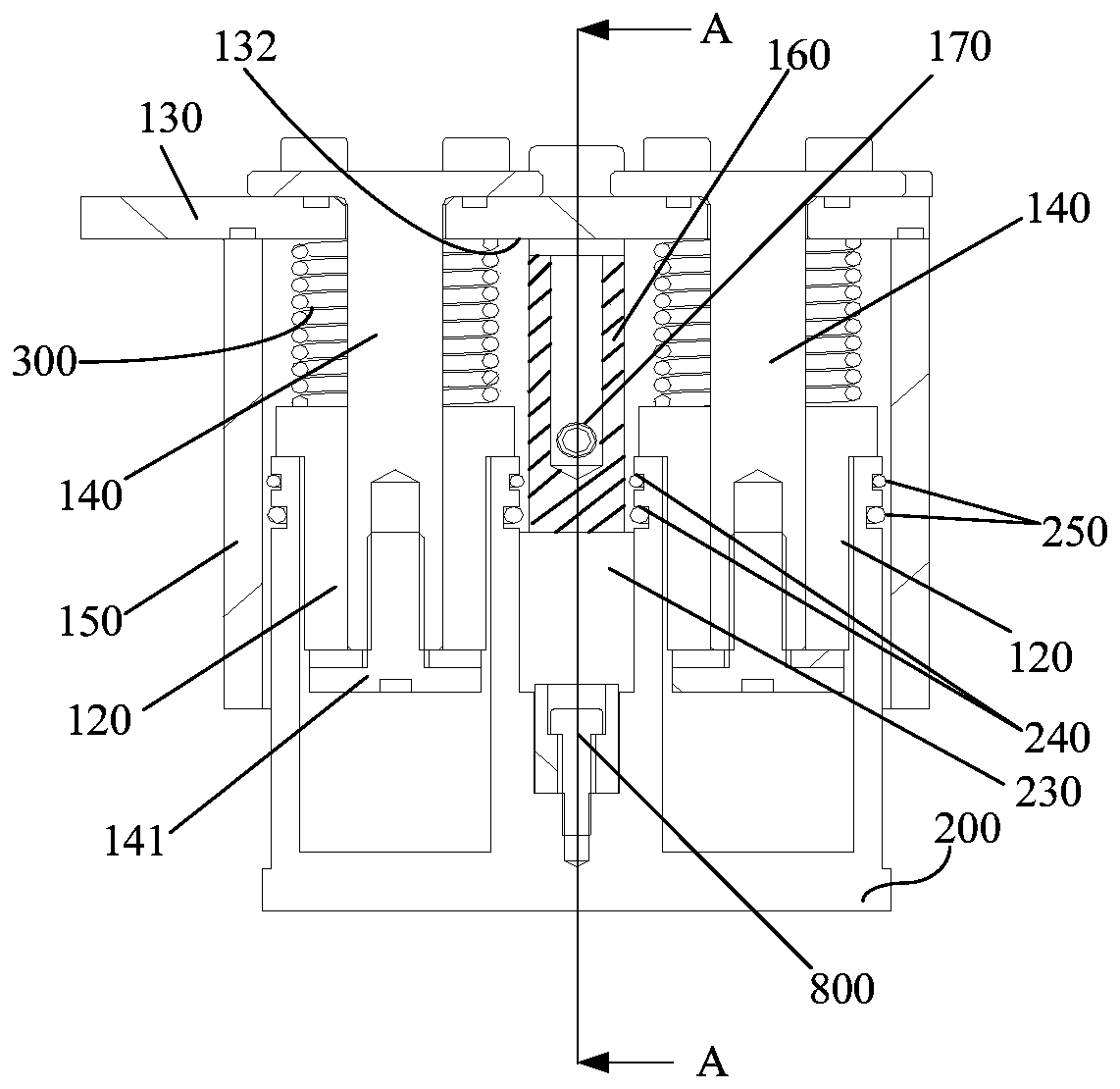

[0072] As an implementation manner, the linkage relationship between the elastic element 300 and the moving mechanism 200 includes:

[0073] When the moving mechanism 200 is in the original position, the elastic element 300 is in the original long state;

[0074] When the moving mechanism 200 moves relative to the fixing mechanism 100, the elastic element 300 generates deformation;

[0075] There is a functional relationship between the displacement of the moving mechanism 200 and the deformation of the elastic element 300 .

[0076] In the above implementation process, when the moving mechanism 200 is at the original position and the elastic element 300 is in the original length state, the two have the same reference contrast, which facilitates the establishment of a comparison between the displacement of the moving mechanism 200 and the deformation of the elastic element 300. Concise functional relationships.

[0077] In a possible implementation manner, the functional rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com