Plate storage and transportation tray

A pallet and plate technology, applied in the field of steel, can solve the problems of repetitive and cumbersome actions, affect the later process, and long loading and unloading time, and achieve the effects of convenient pallet loading and unloading, long service life and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

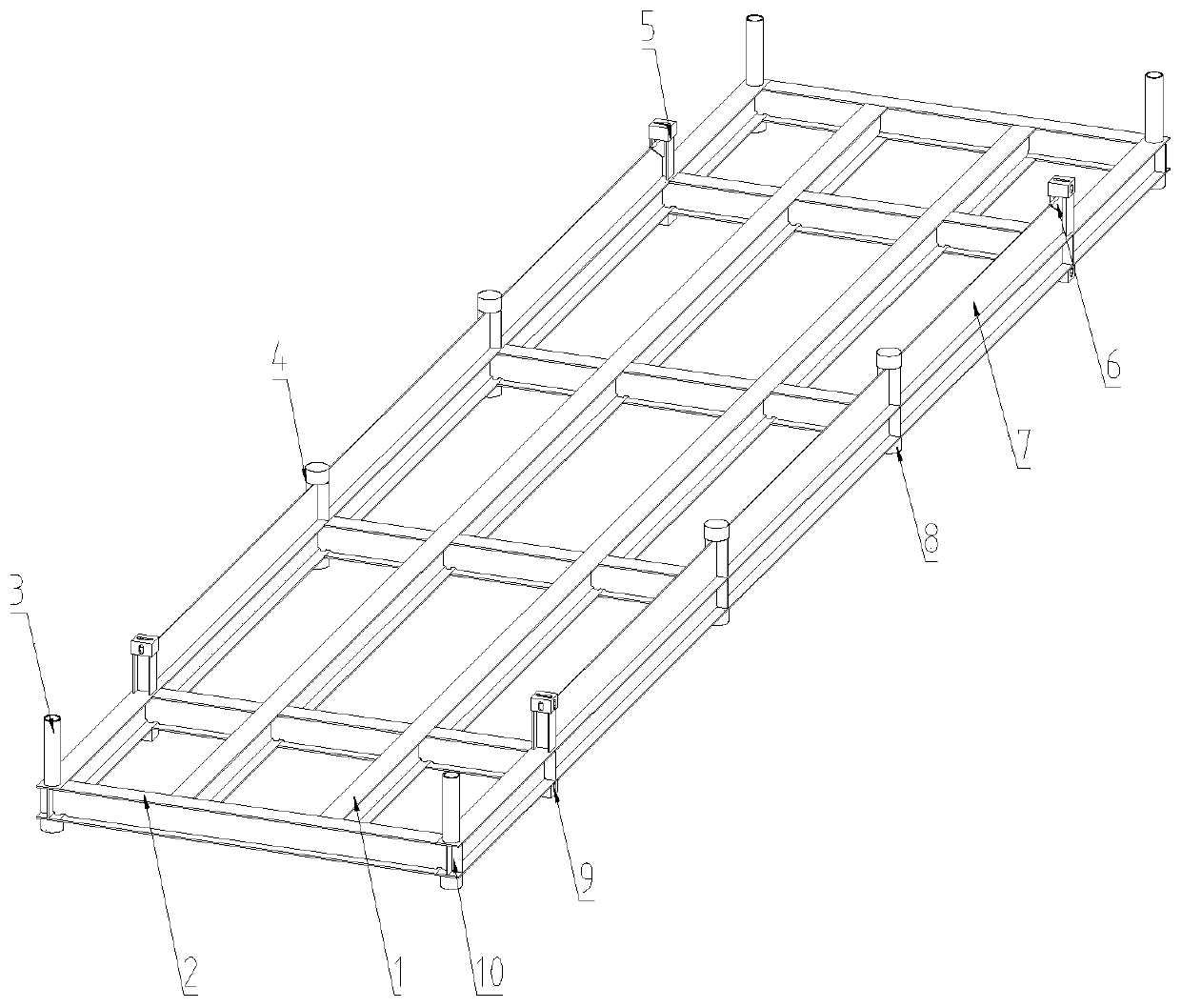

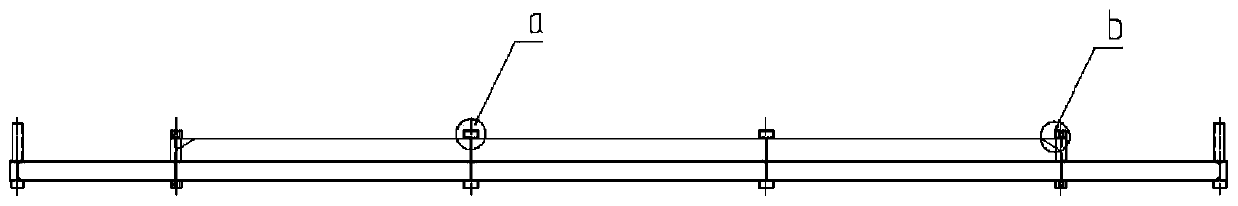

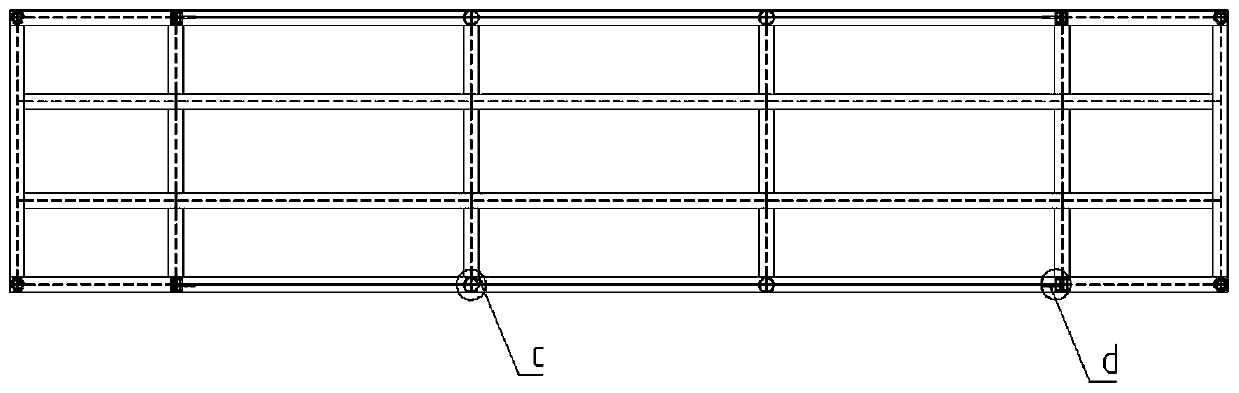

[0022] Such as Figure 1~4 The plate storage and transportation pallet shown includes the main frame of the pallet, pillars, pillar bases and guardrails; the main frame of the pallet is a grid-like rectangular structure formed by welding four H-shaped steel longitudinal beams 1 and six H-shaped steel beams 2; the pillars are set on At the junction of longitudinal beam 1 and cross beam 2 on the long sides of the rectangular structure, the pillars are perpendicular to the plane of the main frame of the pallet, and the joints between the pillars, the longitudinal beams and the cross beams are reinforced with brackets 10; the pillars in the middle part of the two long sides of the rectangular structure of the main frame of the pallet The rooms are connected to each other through the guardrail 7; the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com