Chromium-molybdenum steel plate for high-alloy American-standard container and production method of chromium-molybdenum steel plate

A production method and steel plate technology, which is applied in the field of metallurgy, can solve the problems of steel ingot stress cracks, cracks, cost increase, etc., and achieve the effects of stable and uniform performance, improved flaw detection pass rate, and good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

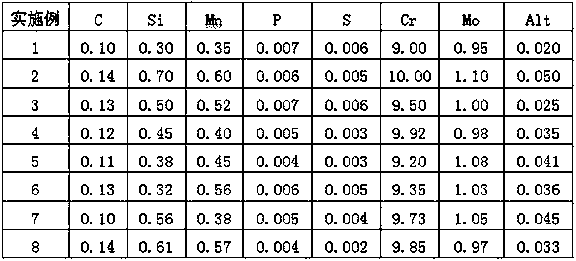

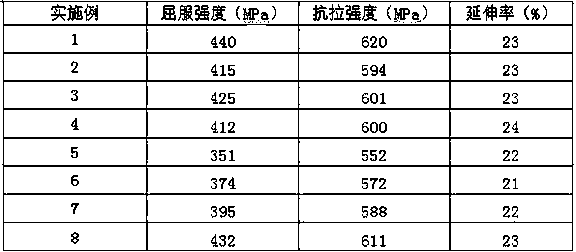

[0019] In this embodiment, the specification of SA387Gr9CL2 steel plate for high-alloy American standard container is 50 mm, and the chemical composition and mass percentage of the steel plate are shown in Table 1.

[0020] The production method of the SA387Gr9CL2 steel plate for the high-alloy American standard container of this embodiment comprises smelting, continuous casting, heating, and rolling operations, and the specific process steps are:

[0021] (1) Continuous casting process: After smelting, the molten steel is continuously cast to obtain steel ingots, and the specification of the steel ingots is 10t;

[0022] (2) Heating process: the steel ingot is heated in a soaking furnace, and the heating atmosphere of the soaking furnace is: the slight positive pressure of the furnace is 15Pa, and the oxygen content of the weak oxidizing atmosphere is 2%; multi-platform gradient heating and heat preservation are adopted, and the soaking pit Open the cover and cool to 500°C to...

Embodiment 2

[0026] In this embodiment, the specification of SA387Gr9CL2 steel plate for high-alloy American standard container is 52 mm, and the chemical composition and mass percentage of the steel plate are shown in Table 1.

[0027] The production method of the SA387Gr9CL2 steel plate for the high-alloy American standard container of this embodiment comprises smelting, continuous casting, heating, and rolling operations, and the specific process steps are:

[0028] (1) Continuous casting process: After smelting, the molten steel is continuously cast to obtain steel ingots, and the specification of the steel ingots is 15t;

[0029] (2) Heating process: the steel ingot is heated in a soaking furnace, and the heating atmosphere of the soaking furnace is: the slight positive pressure of the furnace is 25Pa, and the oxygen content of the weak oxidizing atmosphere is 3%; multi-platform gradient heating and heat preservation are adopted, and the soaking pit Open the cover and cool to 700°C to...

Embodiment 3

[0033] In this embodiment, the specification of SA387Gr9CL2 steel plate for high-alloy American standard container is 54 mm, and the chemical composition and mass percentage of the steel plate are shown in Table 1.

[0034] The production method of the SA387Gr9CL2 steel plate for the high-alloy American standard container of this embodiment comprises smelting, continuous casting, heating, and rolling operations, and the specific process steps are:

[0035] (1) Continuous casting process: After smelting, the molten steel is continuously cast to obtain steel ingots, and the specification of the steel ingots is 17t;

[0036] (2) Heating process: the steel ingot is heated in a soaking furnace, and the heating atmosphere of the soaking furnace is: the slight positive pressure of the furnace is 20Pa, and the oxygen content of the weak oxidizing atmosphere is 2.5%; multi-platform gradient heating and heat preservation are adopted, and the soaking pit Open the cover and cool to 600°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com