4Cr13 plastic die steel and preparation method thereof

A plastic mold steel, 4cr13 technology, applied in the field of plastic mold steel, can solve the problems of high hardness and difficult cutting process, and achieve the effect of improving cutting performance, reducing hardness and good internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] Further, the present invention also provides a method for preparing the 4Cr13 plastic mold steel, which includes the following steps: smelting molten steel with the chemical composition, casting, forging, annealing heat treatment, and pre-hardening treatment.

[0026] The preferred process conditions for the annealing heat treatment step are as follows: first, heat preservation at 780° C. to 820° C. for 8 to 12 hours, and then cool to below 400° C. at a cooling rate of ≤30° C. / h.

[0027] Insulation at 780°C to 820°C for 8 to 12 hours can fully spheroidize or granulate carbides. The investigation shows that too low temperature or too short holding time will lead to insufficient spheroidization of carbides, and too high temperature or too long holding time will cause carbides to aggregate and grow.

[0028] Cooling to below 400°C at a cooling rate of ≤30°C / h can avoid the reduction of strength and toughness due to the presence of retained austenite.

[0029] The preferr...

Embodiment 1

[0033] The preparation of embodiment 1 present invention 4Cr13 plastic mold steel

[0034] Using LF electric arc furnace smelting + electroslag remelting to form Φ880mm electroslag ingot, its chemical composition is shown in Table 1, after forging at 850℃~1200℃ to form a plastic mold steel plate with a thickness of 100mm and a width of 610mm, and then annealing heat treatment + pre-heating Hardening heat treatment.

[0035] Among them, the annealing heat treatment process is: first, heat preservation at 800°C for 10 hours; then cool to 350°C at a cooling rate of 25°C / h, and then cool naturally to room temperature.

[0036] The pre-hardening treatment process is as follows: first heat preservation at 850°C for 8 hours, then cool to 400°C; then heat to 720°C and temper for 22 hours, then cool to 400°C at a cooling rate of 25°C / h, and finally take out the furnace and air cool.

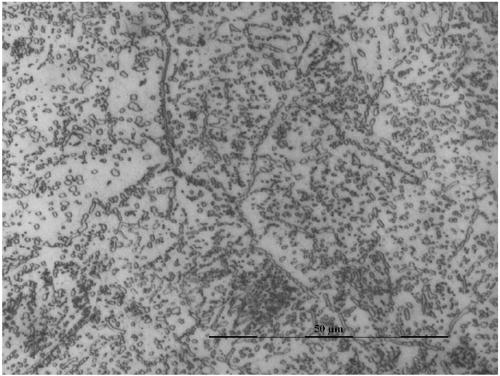

[0037] The metallographic structure of 4Cr13 plastic mold steel produced by this method is martensite...

Embodiment 2

[0039] Embodiment 2 The preparation of 4Cr13 plastic mold steel of the present invention

[0040] Using LF electric arc furnace smelting + VD vacuum degassing, and then pouring into 3.2 tons of flat ingot, its chemical composition is shown in Table 1, after forging at 850 ℃ ~ 1200 ℃ into a plastic mold steel plate with a thickness of 150mm and a width of 610mm, and then annealed Heat treatment + pre-hardening heat treatment.

[0041] Among them, the annealing heat treatment process is: first, heat preservation at 800°C for 12 hours; then cool to 350°C at a cooling rate of 25°C / h, and then cool naturally to room temperature.

[0042] The pre-hardening treatment process is as follows: first, heat preservation at 850°C for 10 hours, then cool to 400°C; then heat to 720°C and temper for 24 hours, then cool to 400°C at a cooling rate of 25°C / h, and finally take out the furnace and air cool.

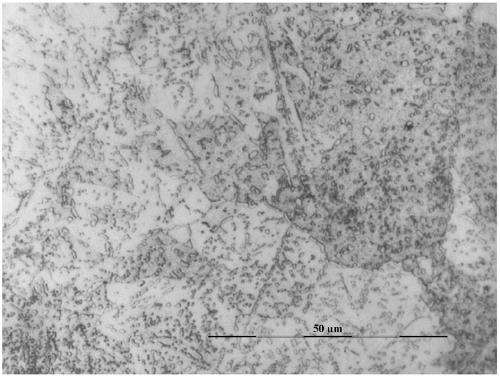

[0043] The metallographic structure of 4Cr13 plastic mold steel produced by this method i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com