Circular assembled underground integrated pipe gallery constructed through grouting method

A comprehensive pipe gallery and prefabricated technology, used in artificial islands, water conservancy projects, underwater structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

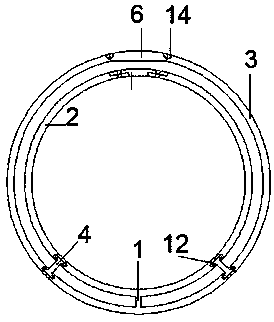

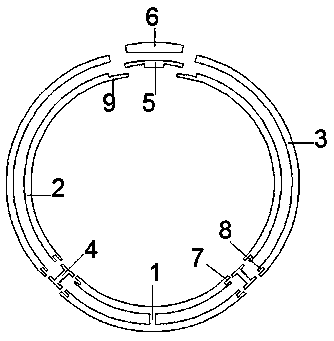

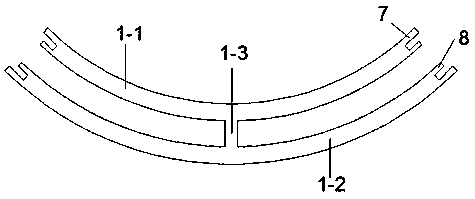

[0029] Such as figure 1 As shown in -8, a circular assembled underground comprehensive pipe gallery constructed by grouting method includes a prefabricated double-layer pipe gallery base 1, an inner gallery body 2, an outer gallery body 3, H-shaped connectors 4, and an inner layer Cover plate 5, outer cover plate 6, rectangular rib 1 7, rectangular rib 2 8, arc rib 9, rectangular groove 10, corridor body connector 11, high-strength bolt 12, reserved bolt hole 13, U-shaped bolt 14, Reserve U-shaped bolt holes 15, waterproof rubber cushion layer 16;

[0030] The prefabricated double-layer pipe gallery base 1, two inner gallery bodies 2 and two outer gallery bodies 3 on both sides cooperate with the inner layer cover plate 5 and the outer layer cover plate 6 to form the pipe gallery body; the described The base 1 of the prefabricated double-layer pipe gallery is a prefabricated double-layer structure, the inner and outer layers are connected by rectangular prefabricated panels, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com