Concrete structure joint anti-seepage construction method

A technology for concrete structures and construction methods, which is applied in basic structural engineering, underwater structures, artificial islands, etc., can solve problems such as affecting the normal use and durability of concrete structural engineering, troublesome leakage control, and lack of gripping force. , to achieve the effect of overcoming anti-leakage treatment, high construction efficiency and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

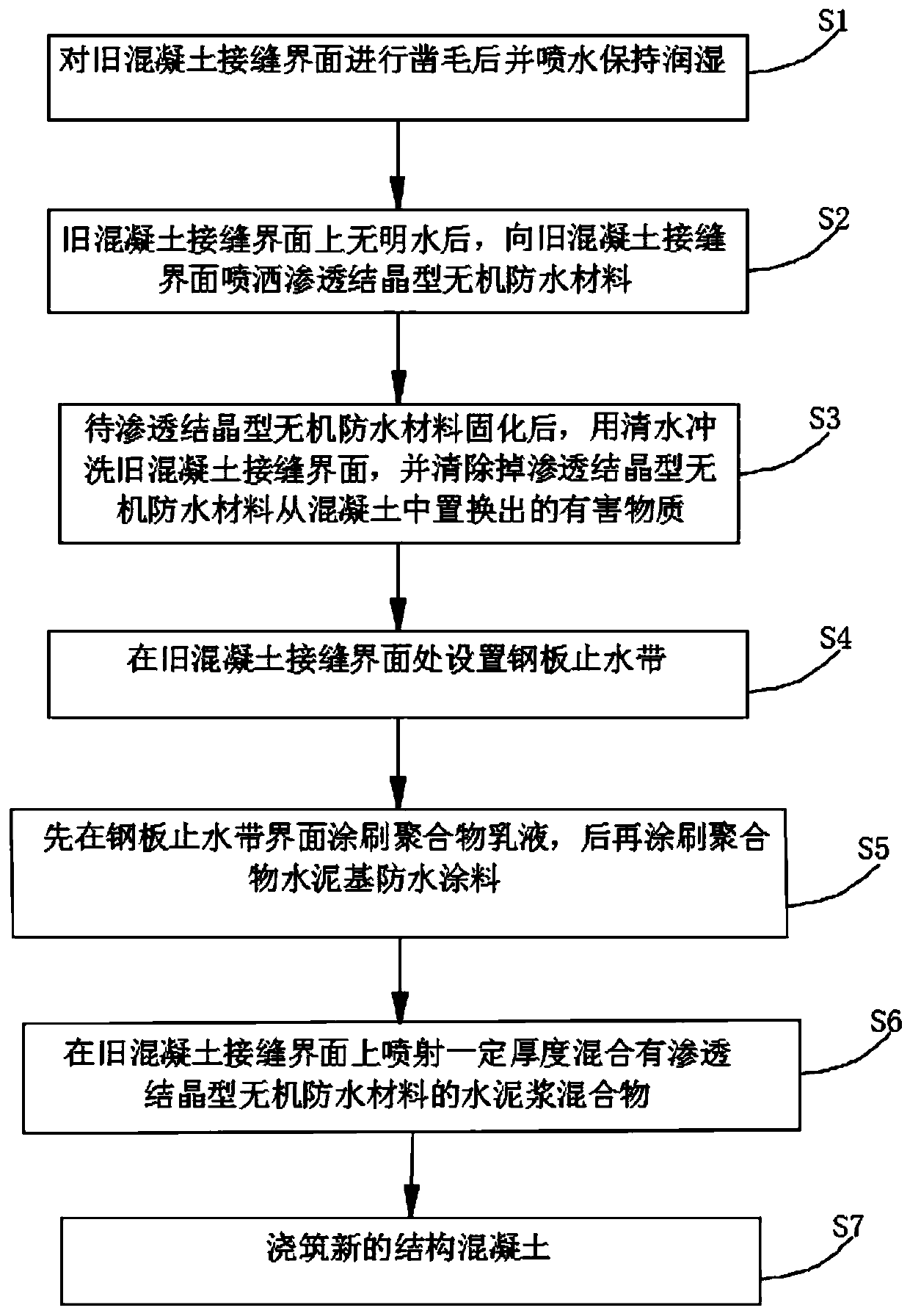

[0036] Please refer to figure 1 , A construction method for preventing leakage of concrete structure joints, including the following steps:

[0037] S1. After chipping the old concrete joint interface and spraying water to keep it wet;

[0038] S2. After there is no clear water on the joint interface of the old concrete, spray permeable crystalline inorganic waterproof material on the joint interface of the old concrete;

[0039] S3. After the permeable crystalline inorganic waterproof material is solidified, rinse the joint interface of the old concrete with clean water, and remove the harmful substances replaced by the permeable crystalline inorganic waterproof material from the concrete;

[0040] S4. Set steel waterstop at the interface of the old concrete joint;

[0041] S5. Paint polymer emulsion on the interface of steel waterstop first, and then paint polymer cement-based waterproof coating;

[0042] S6. Spray a certain thickness of cement slurry mixture mixed with permeable crys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com