Multi-stage liquid nitrogen fracturing system and method for hot dry rock geothermal well

A well liquid nitrogen, hot dry rock technology, applied in earthwork drilling, wellbore/well components, production fluids, etc., can solve the problems of large scale, long fracturing period of hot dry rock reservoirs, excessive consumption of water resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

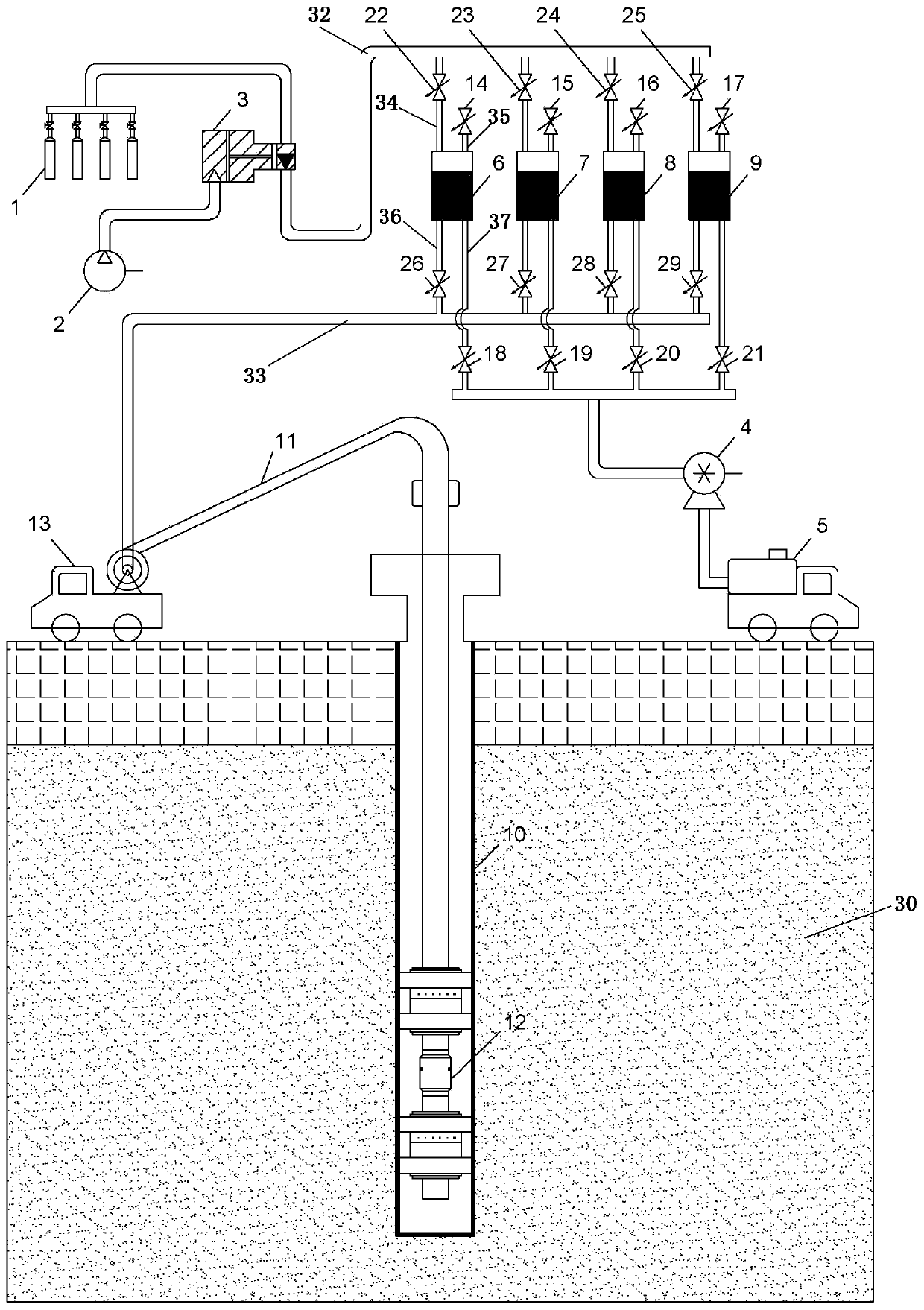

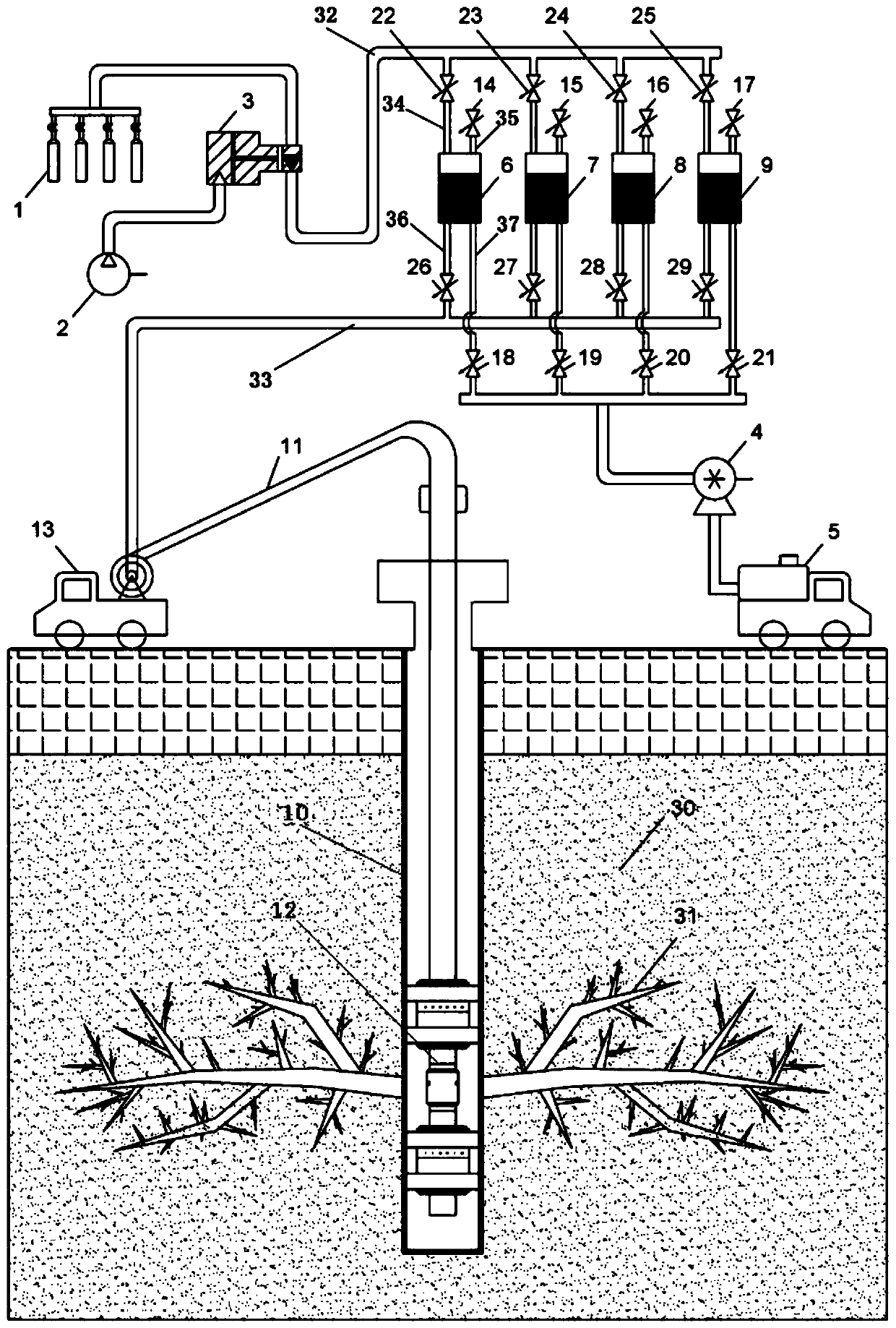

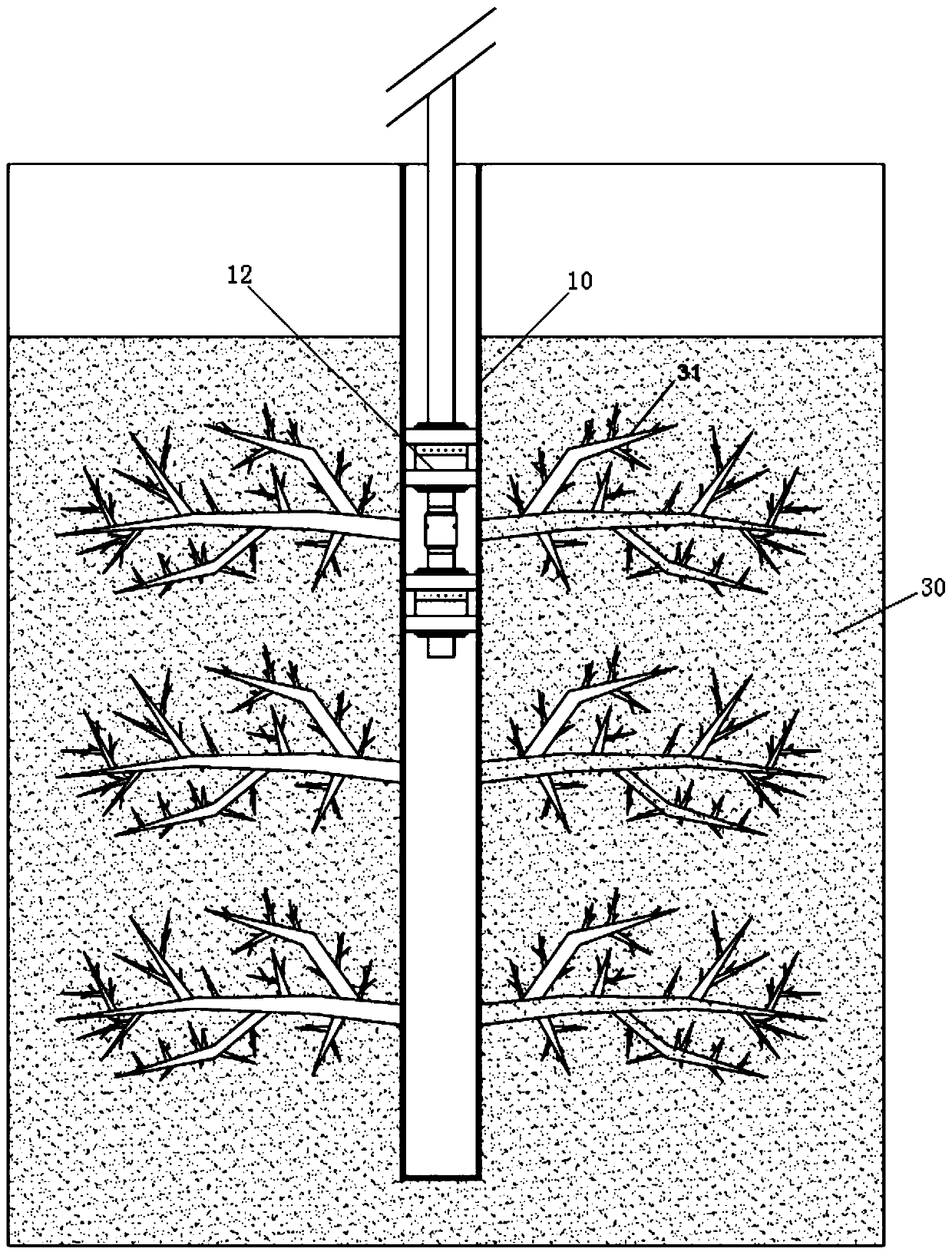

[0033] Such as figure 1 As shown, a liquid nitrogen multistage fracturing system for hot dry rock geothermal wells includes a nitrogen pressurization system, a liquid nitrogen injection system, a total nitrogen input pipeline 32, a total liquid nitrogen discharge pipeline 33 and at least three high-pressure liquid nitrogen container;

[0034] The upper ends of the three high-pressure liquid nitrogen containers are provided with a nitrogen gas inlet pipeline 34 and a vent pipeline 35, and the lower ends are equipped with a liquid nitrogen outlet pipeline 36 and a liquid nitrogen inlet pipeline 37. The three high-pressure liquid nitrogen containers are respectively These are high-pressure liquid nitrogen container A6, high-pressure liquid nitrogen container B7 and high-pressure liquid nitrogen container C8. The nitrogen inlet pipeline 34 and the liquid nitrogen outlet pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com