Fuel tank oil level sensor

A technology of oil level sensor and fuel tank, which is applied in the field of sensors, can solve the problems of reducing the service life of the oil level sensor, damage to the rod body or floating body of the oil level sensor, and achieve the effects of reducing the shaking of the rod body, simple structure, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

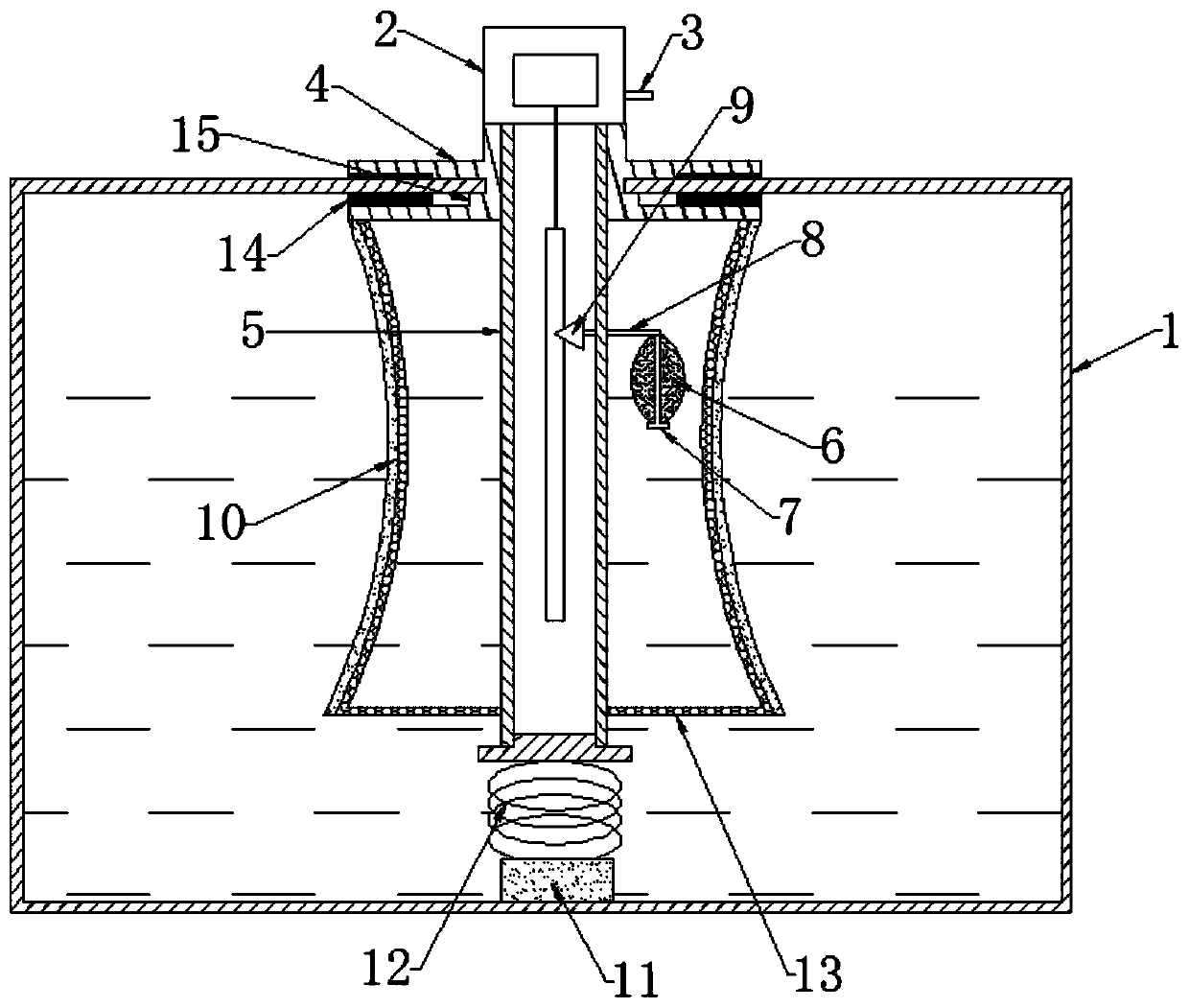

[0015] Such as figure 1 As shown, the present invention is an oil level sensor for a fuel tank. The oil level sensor device installed on the fuel tank 1 includes a circuit box 2, a signal line 3, a flange 4, and a rod body 5. A floating body is provided on the side of the rod body. The floating body includes a football-like float 6 arranged vertically, the axis position of the float is pierced with a floating column 7, and the float is rotatably connected with the floating column, and the floating column slides through the swing arm 8 and the rod body. The contact piece 9 is connected.

[0016] A buffer sleeve 10 is sheathed on the outside of the rod body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com