Communication wire harness type conversion module unit and unit box

A conversion module and module box technology, which is applied in the direction of optical components, light guides, optics, etc., can solve the problems of poor operation and maintenance convenience of module units, easy and fast installation of module unit boxes, increase and decrease of lines, low deployment efficiency and other problems , to achieve the effect of convenient unit combination and independent use, fast and efficient deployment, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

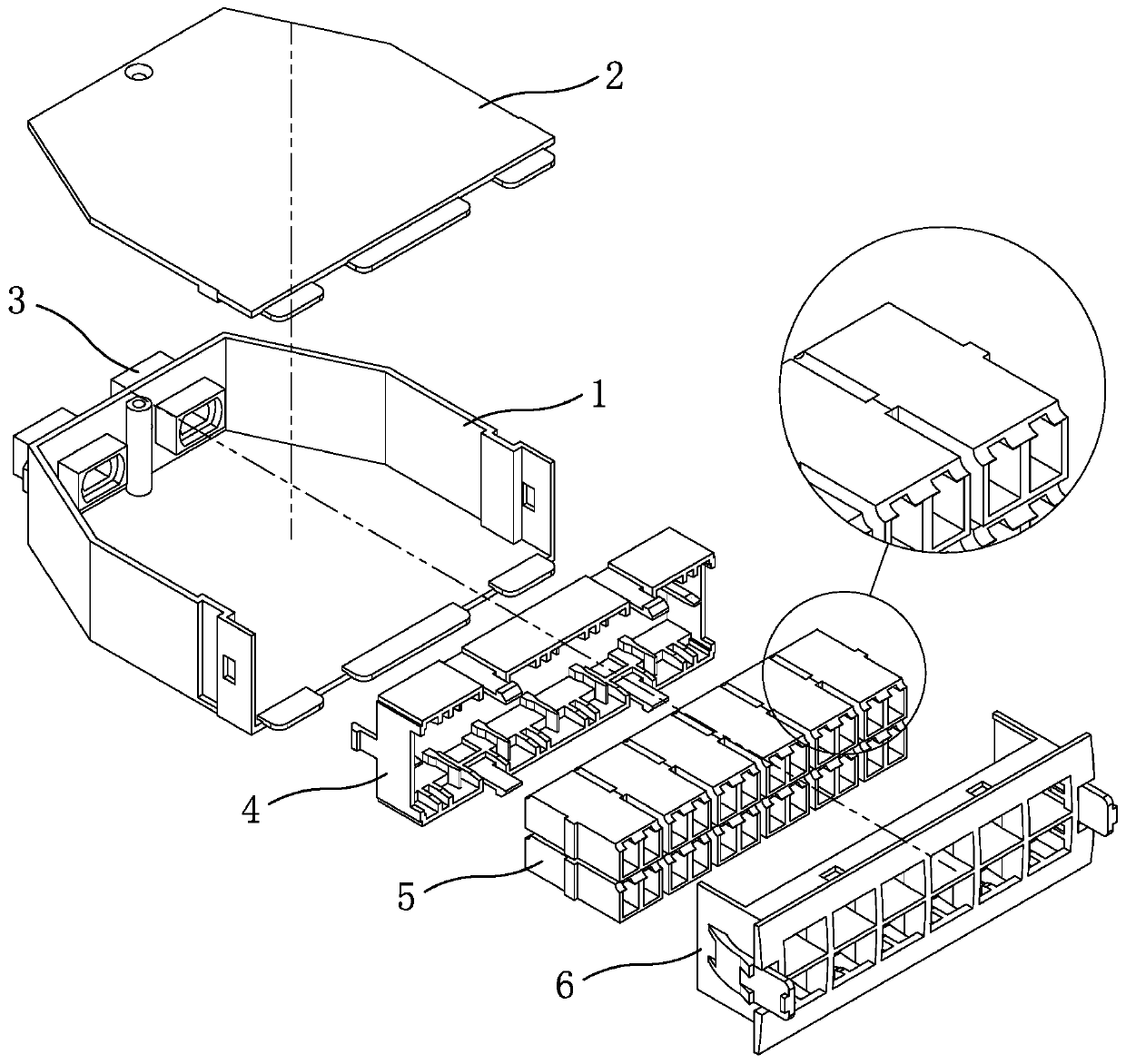

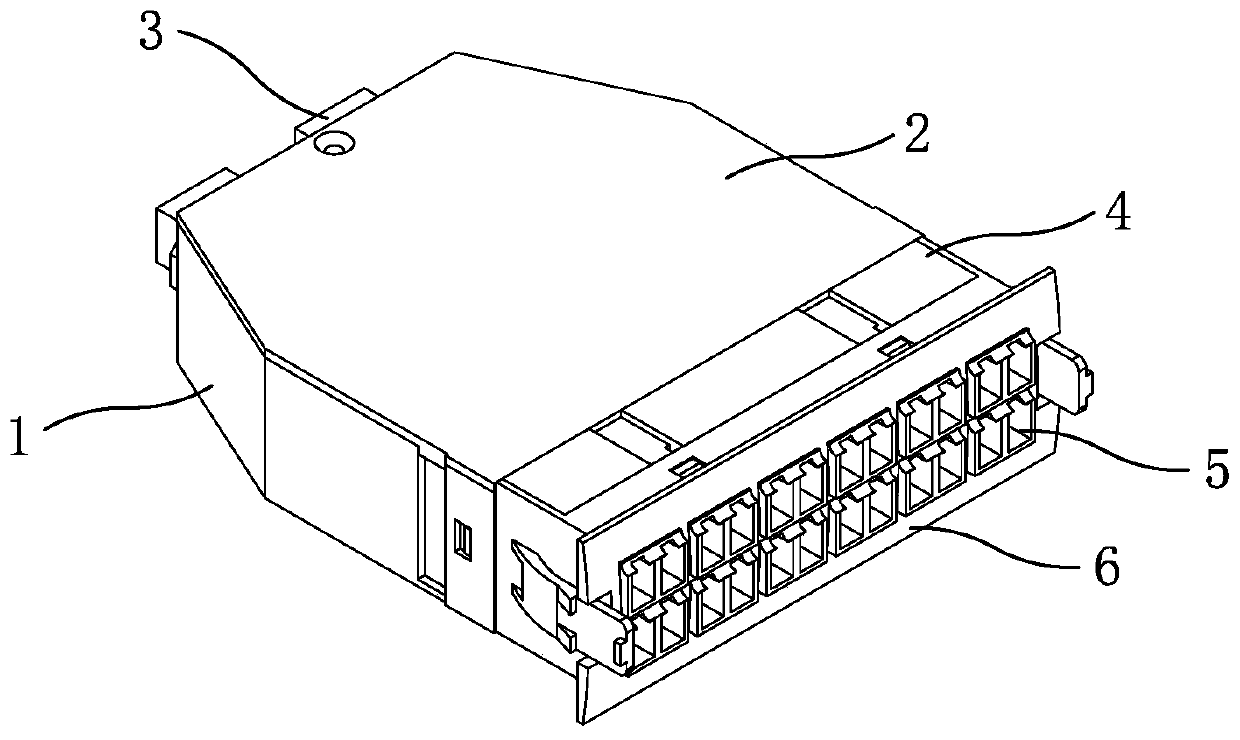

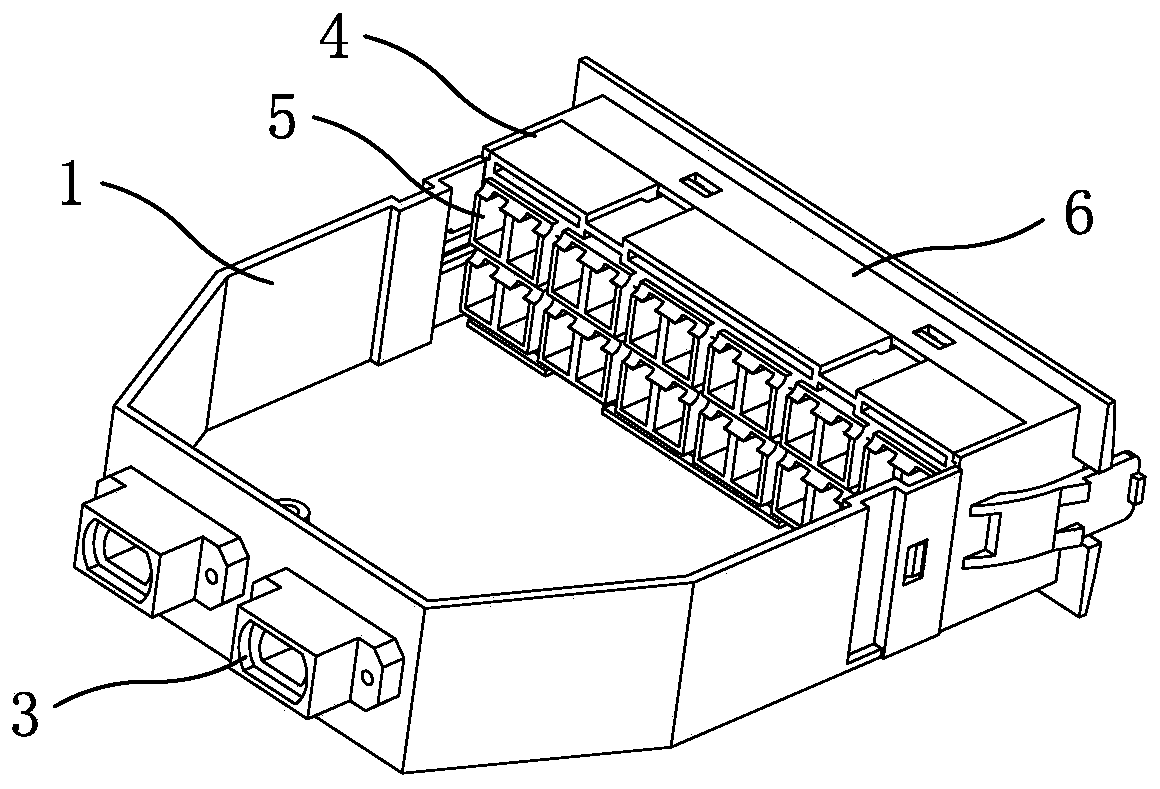

[0031] Now in conjunction with the accompanying drawings, the structure and use of the present invention will be further described. Such as Figure 1-Figure 6 As shown, the module unit box is a new type of optical fiber protection box structure in which an integrated adapter is converted into an independent adapter. The module box body 1 is a cavity box body composed of a rectangular front end and a trapezoidal rear end. The top and front end of the module box body are one There is an opening on the side, and the cover plate 2 is buckled correspondingly to the top opening of the module box body. Evenly distributed optical fiber independent adapters 5 are arranged inside the insert block 4, and the optical fiber independent adapters are fixed between the insert block and the panel, and the insert block is fastened to the panel As a whole, the insert block is fastened and fixed to the opening on one side of the front end formed by the module box body and the cover plate. Its sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com