Automatic Intelligent Scheduling Method for Off-line Vehicles in Factory

A technology of intelligent dispatching and vehicles, applied in the direction of comprehensive factory control, comprehensive factory control, control/regulation system, etc., can solve the problems that the automatic movement of vehicles cannot be realized, and achieve the effect of being suitable for large-scale promotion, saving labor and being easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings, so that those of ordinary skill in the art can implement it after referring to this specification.

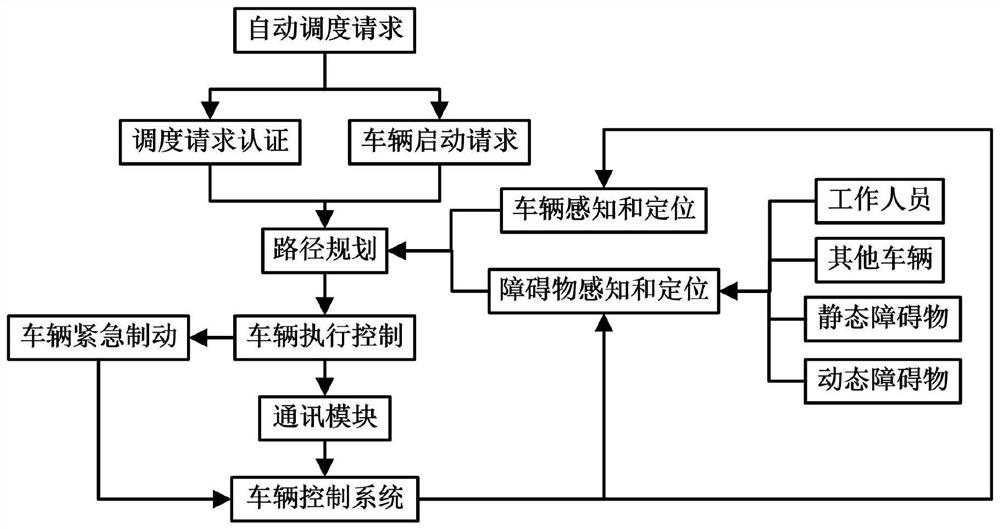

[0026] like figure 1 As shown, an automatic intelligent scheduling method for off-line vehicles in a factory mainly includes the following steps:

[0027] S1. Arrange a plurality of laser radars for scanning vehicles along the vehicle factory station to the factory parking area to form a laser radar scanning network covering the vehicle factory station to the factory parking area, and based on the laser radar scanning network to generate A map describing the parking information of the factory parking area.

[0028] S2. Set up a server connected to the lidar scanning network for real-time reception of the dispatch request sent by the vehicle factory station and the status information of the parking space in the factory parking area.

[0029] S3. After receiving the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com