Bar-shaped smoke formation section, preparation method thereof, and cigarette stick including bar-shaped smoke formation section

A technology of cigarette section and stick, which is applied in the field of bar-shaped smoking section and its preparation, can solve the problems of filter section manufacturing difficulty, high processing cost, and increased suction resistance, and avoid high processing strength requirements and contact Large area, easy to reduce the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

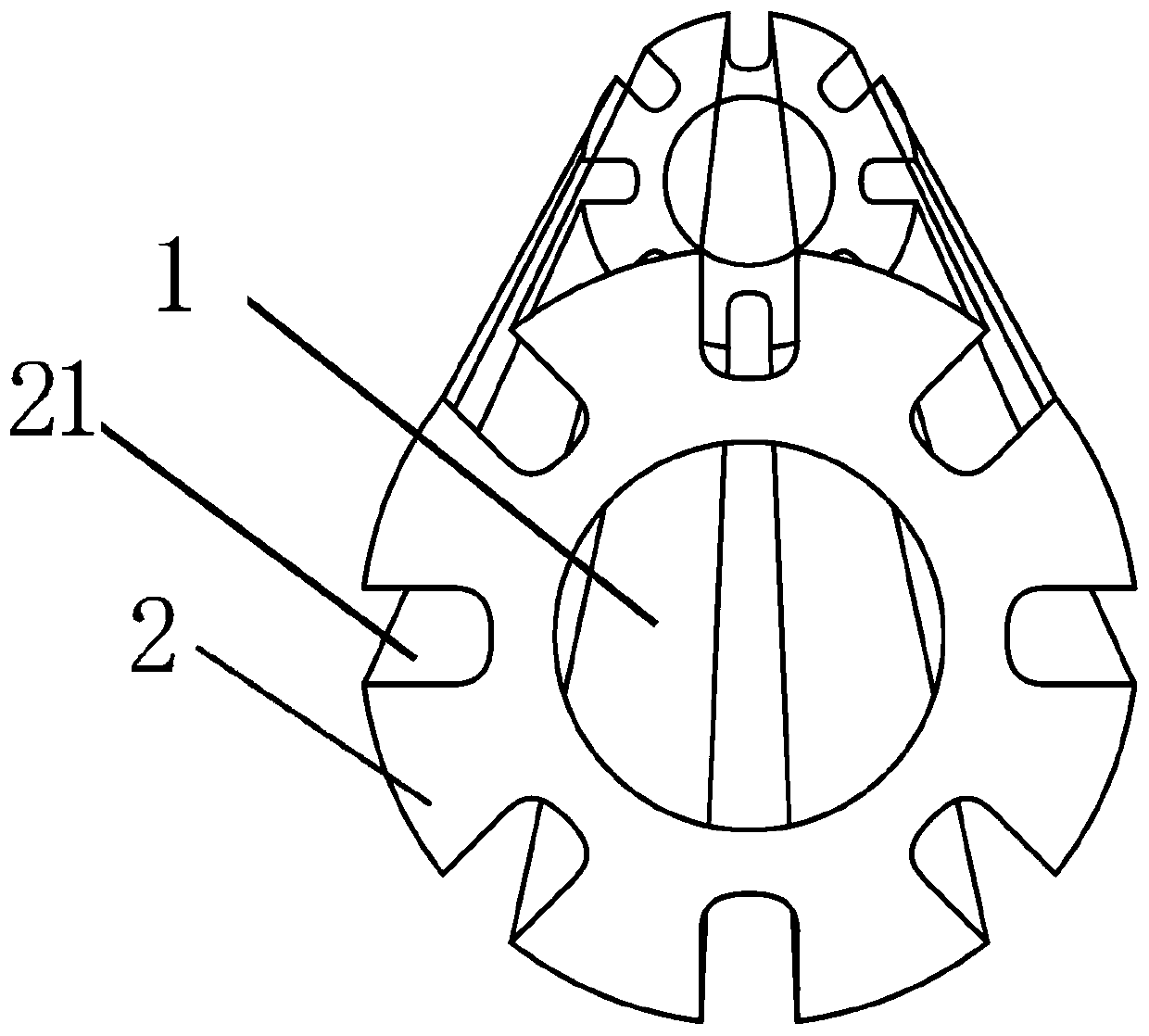

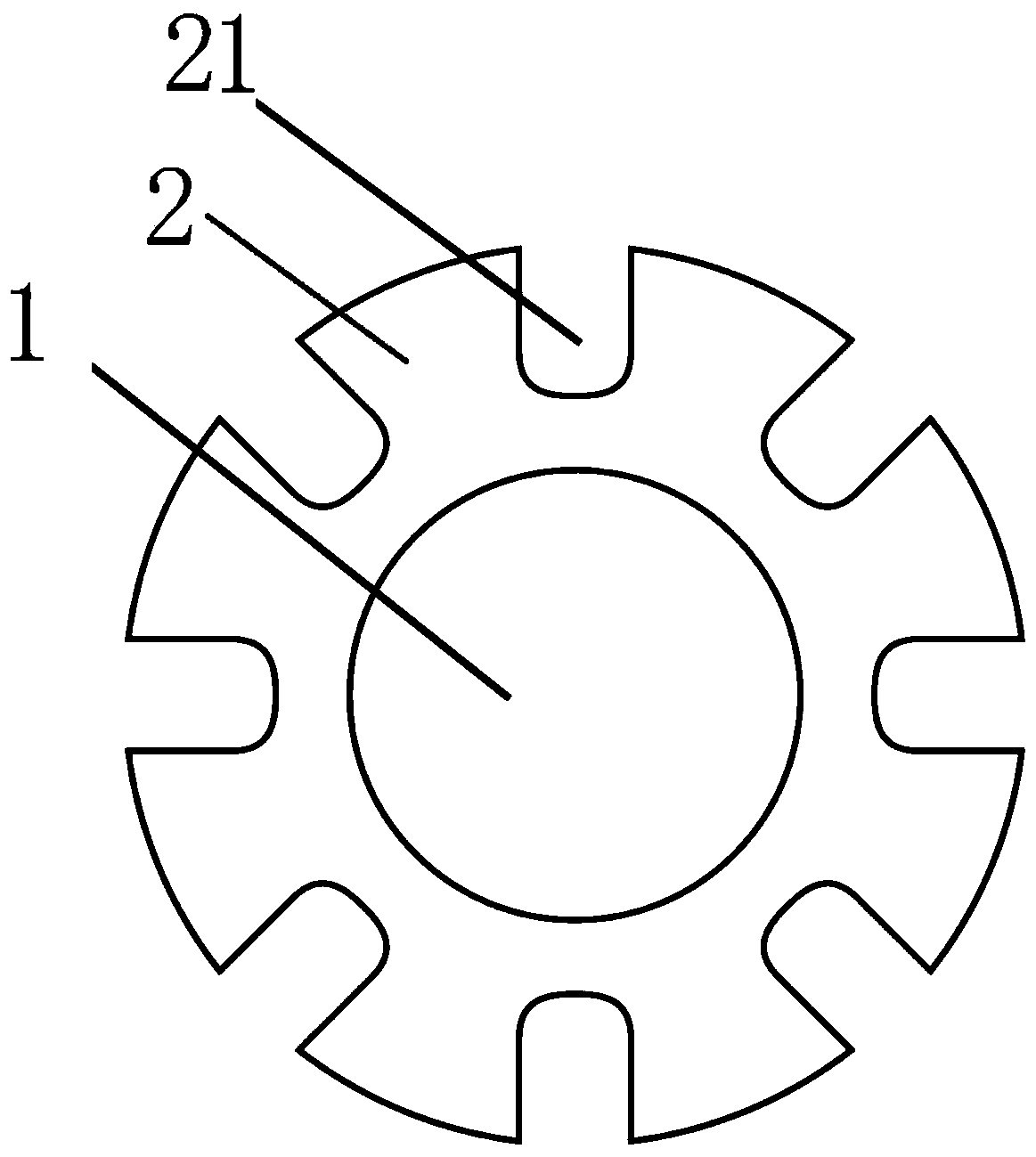

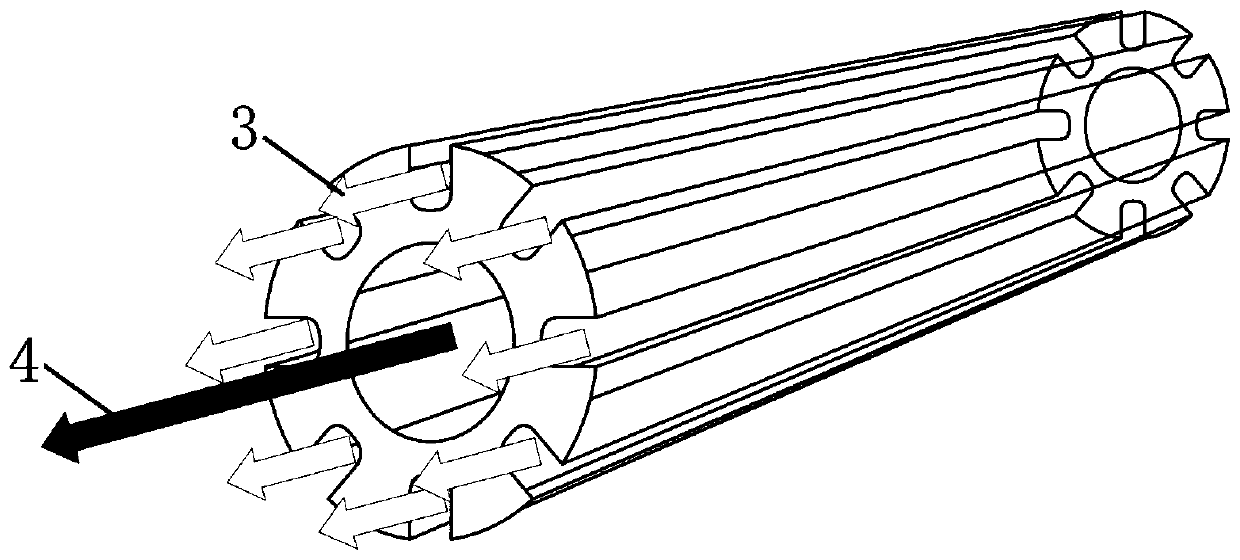

[0038] The smoking section in this embodiment is a hollow rod-shaped structure with a tube cavity 1 and a tube wall 2 ; the tube wall 2 has an axially extending groove 21 , and the opening of the groove 21 faces away from the tube cavity 1 .

[0039] Said groove 21 extends axially the entire length of said tube wall 2 .

[0040] The number of the grooves 21 is 8.

[0041] The cross section of the groove 21 is "U" shape; the cross section of the lumen 1 is circular.

[0042] The depth of the groove 21 is 1 mm.

[0043] The diameter of the lumen 1 is 2 mm.

[0044] The preparation method of the smoking section of the present embodiment comprises the following steps:

[0045] (1) breaking the fuming base material into powder to obtain a powdery fuming base material;

[0046] (2) Mix the powdery fuming base material obtained in step (1) with the filler, add fuming agent and essence and fragrance, stir and mix to obtain the fuming section mixture;

[0047] (3) Molding the smok...

Embodiment 2

[0052] The smoking section in this embodiment is a hollow rod-shaped structure with a tube cavity 1 and a tube wall 2 ; the tube wall 2 has an axially extending groove 21 , and the opening of the groove 21 faces away from the tube cavity 1 .

[0053] Said groove 21 extends axially the entire length of said tube wall 2 .

[0054] The number of the grooves 21 is 10.

[0055] The cross section of the groove 21 is "U" shape; the cross section of the lumen 1 is circular.

[0056] The depth of the groove 21 is 2 mm.

[0057] The diameter of the lumen 1 is 3 mm.

[0058] The preparation method of the smoking section of the present embodiment comprises the following steps:

[0059] (1) breaking the fuming base material into powder to obtain a powdery fuming base material;

[0060] (2) Mix the powdery fuming base material obtained in step (1) with the filler, add fuming agent and essence and fragrance, stir and mix to obtain the fuming section mixture;

[0061] (3) Molding the smo...

Embodiment 3

[0066] The smoking section in this embodiment is a hollow rod-shaped structure with a tube cavity 1 and a tube wall 2 ; the tube wall 2 has an axially extending groove 21 , and the opening of the groove 21 faces away from the tube cavity 1 .

[0067] Said groove 21 extends axially the entire length of said tube wall 2 .

[0068] The number of the grooves 21 is 12.

[0069] The cross section of the groove 21 is "U" shape; the cross section of the lumen 1 is oval.

[0070] The depth of the groove 21 is 3 mm.

[0071] The cross section of the lumen 1 is elliptical, and the diameter of the major axis of the ellipse is 4 mm.

[0072] The preparation method of the smoking section of the present embodiment comprises the following steps:

[0073] (1) breaking the fuming base material into powder to obtain a powdery fuming base material;

[0074] (2) Mix the powdery fuming base material obtained in step (1) with the filler, add fuming agent and essence and fragrance, stir and mix t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Equivalent diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com