Shoemaking system and method with integrated operation lines

An operation line and integrated technology, applied in the field of shoemaking systems, can solve the problems of large area occupation of process production lines, failure to achieve maximum efficiency, increase costs and plant conditions, etc., to reduce costs, improve plant space utilization, improve The effect of smoothness and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Various embodiments will be described below, and those skilled in the art can easily understand the spirit and principle of the present invention with reference to the description and accompanying drawings. However, while some specific embodiments will be described in detail, these embodiments are illustrative only and are not to be considered restrictive or exhaustive in all respects. Therefore, for those skilled in the art, without departing from the spirit and principles of the present invention, various changes and modifications to the present invention should be obvious and easily achievable.

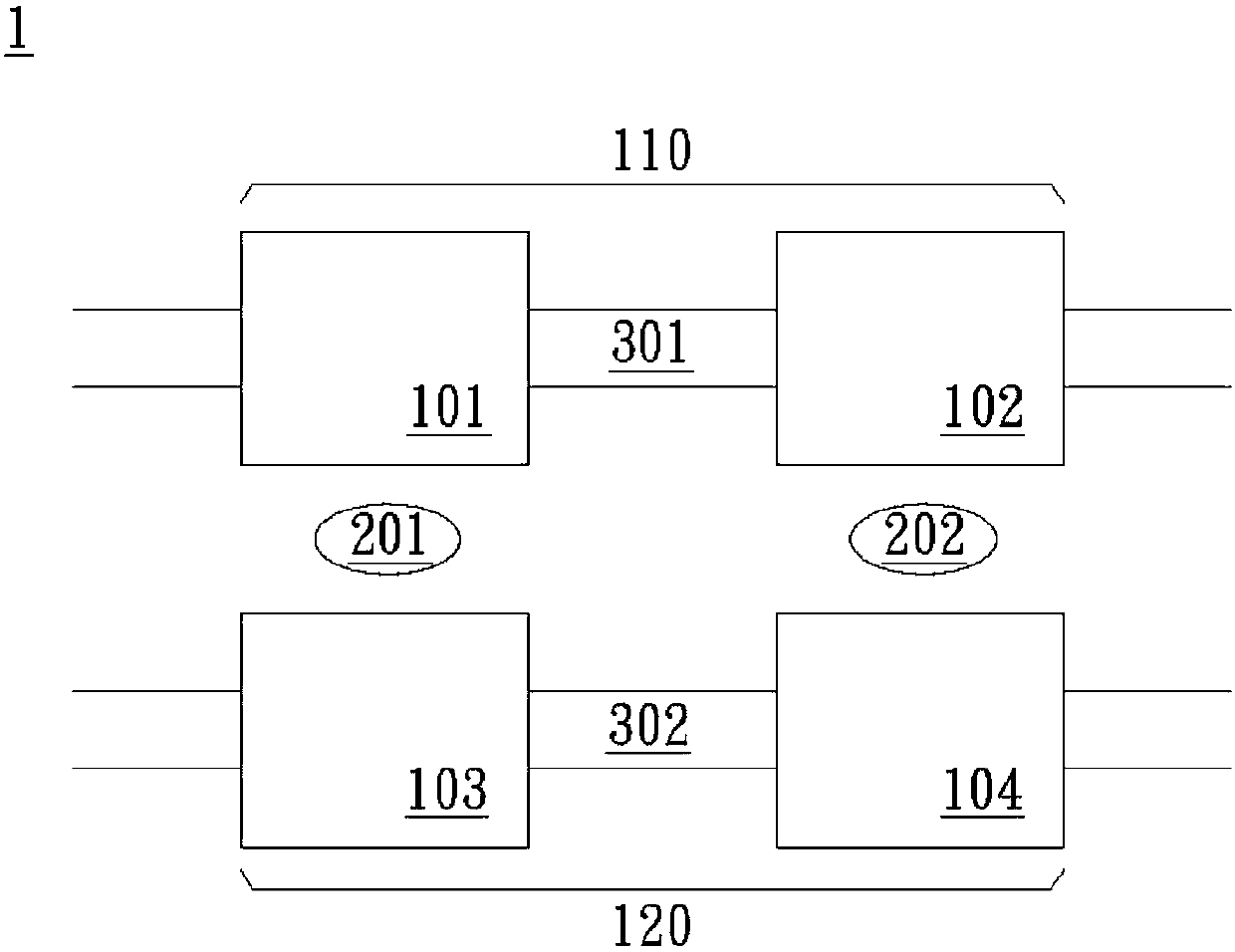

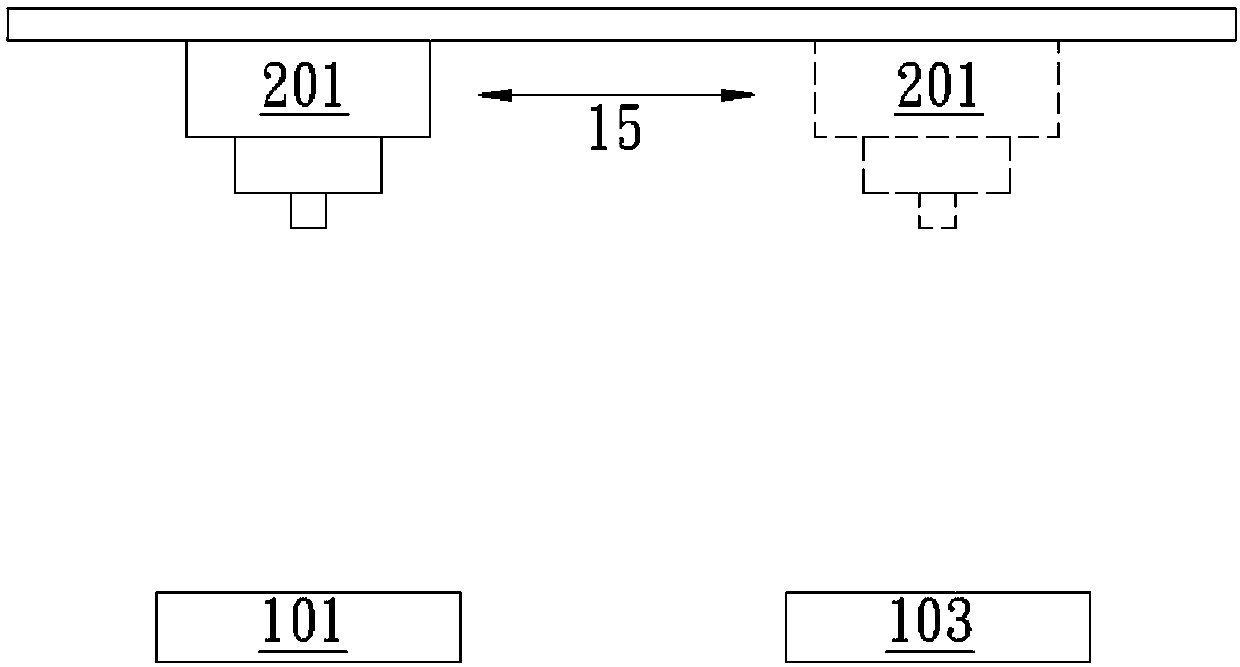

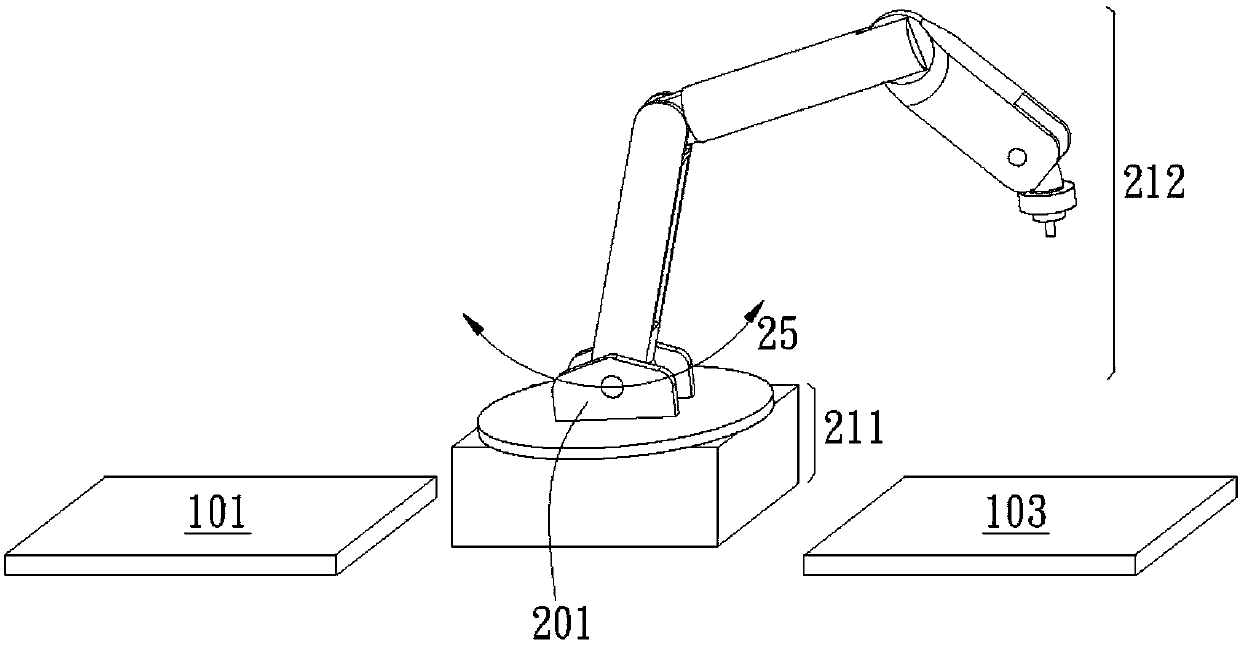

[0056] First, refer to figure 1 A shoemaking system 1 according to an embodiment of the present invention will be described. As above, the shoemaking system 1 includes a first operation area 101, a second operation area 102, a third operation area 103, a fourth operation area 104, a first robot 201, a second robot 202, a first conveyor belt 301, a second Conveyor belt 302 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com