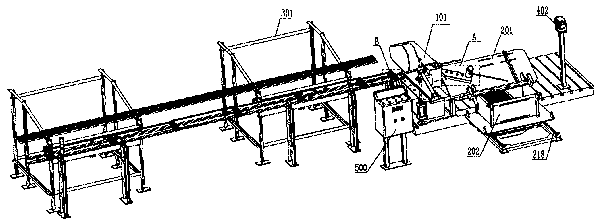

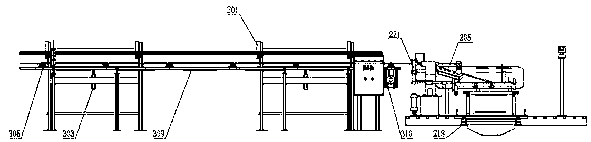

Automatic punching and fallen material collecting device

A collection device and automatic punching technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of time-consuming and labor-intensive, and achieve the effects of avoiding randomness, good blanking collection effect, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

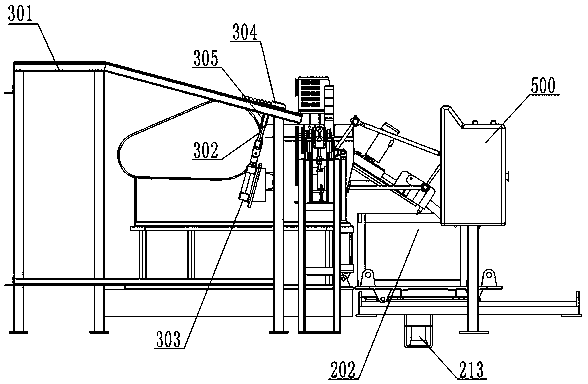

[0025] This embodiment provides an automatic punching blanking collection device, including a punching assembly, a blanking collection assembly and a control system; the punching assembly includes a punching machine tool 101 and a device for punching materials installed on the punching machine tool 101 Cutter; the punching machine tool 101 is provided with a first proximity switch for detecting whether the punching point of the material reaches the cutter; the blanking collection assembly includes a guide plate 201 arranged behind the cutter, a collection box 202 arranged below the guide plate 201, a rotating The gate plate 203 arranged on the guide plate 201 and the first actuator 204 that drives the gate plate 203 to rotate; the guide plate 201 is inclined to the collection box 202; the gate plate 203 is used to prevent the semi-finished products falling on the guide plate 201 from falling into the collection box 202 ; The control system is used to receive the detection signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com