Ship deck oily water treatment system

A technology for ship deck and treatment system, applied in water/sewage treatment, water/sewage treatment equipment, water/sewage multi-stage treatment, etc. The effect of reducing labor load, reducing procurement costs, and reducing the risk of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

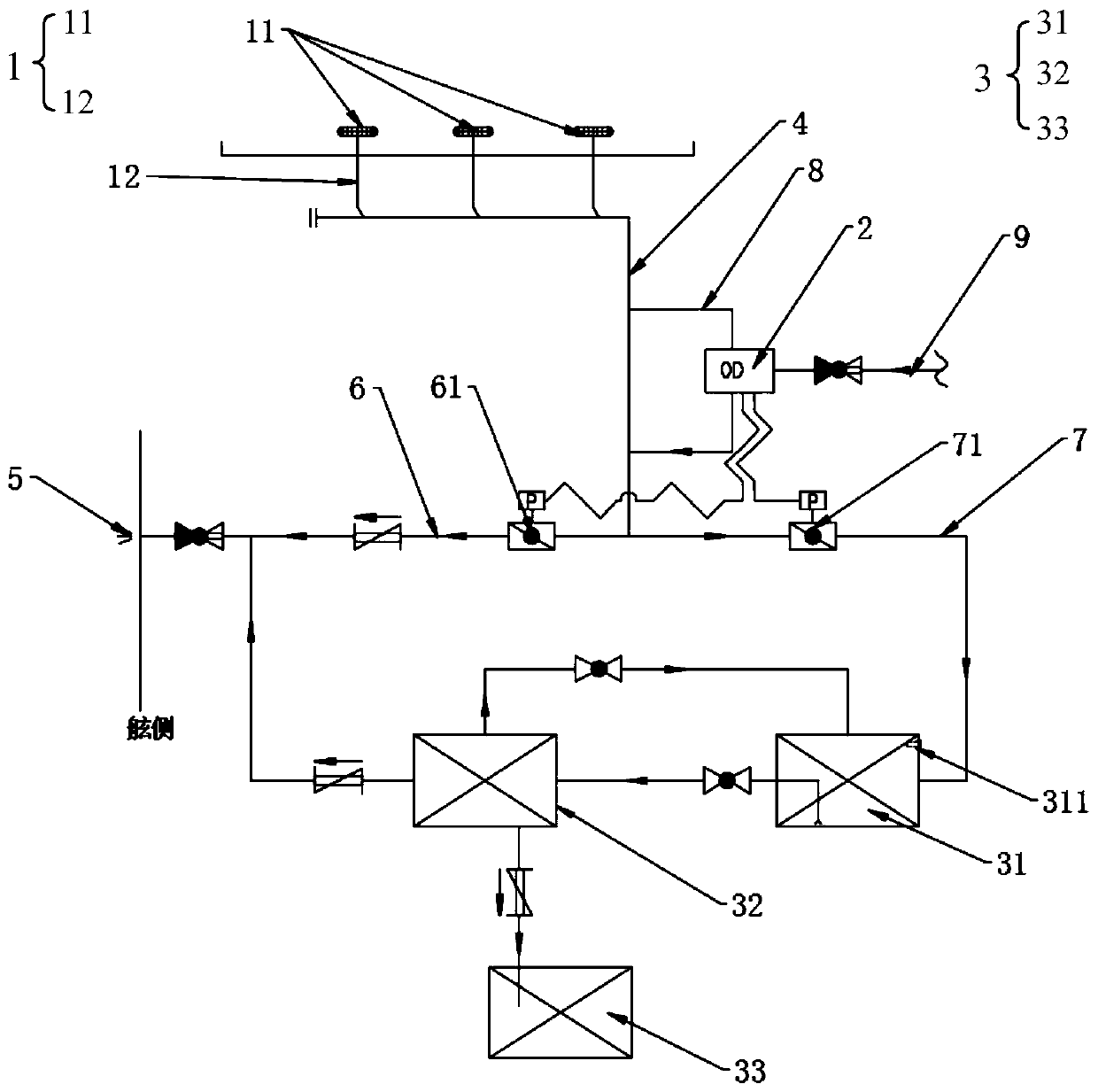

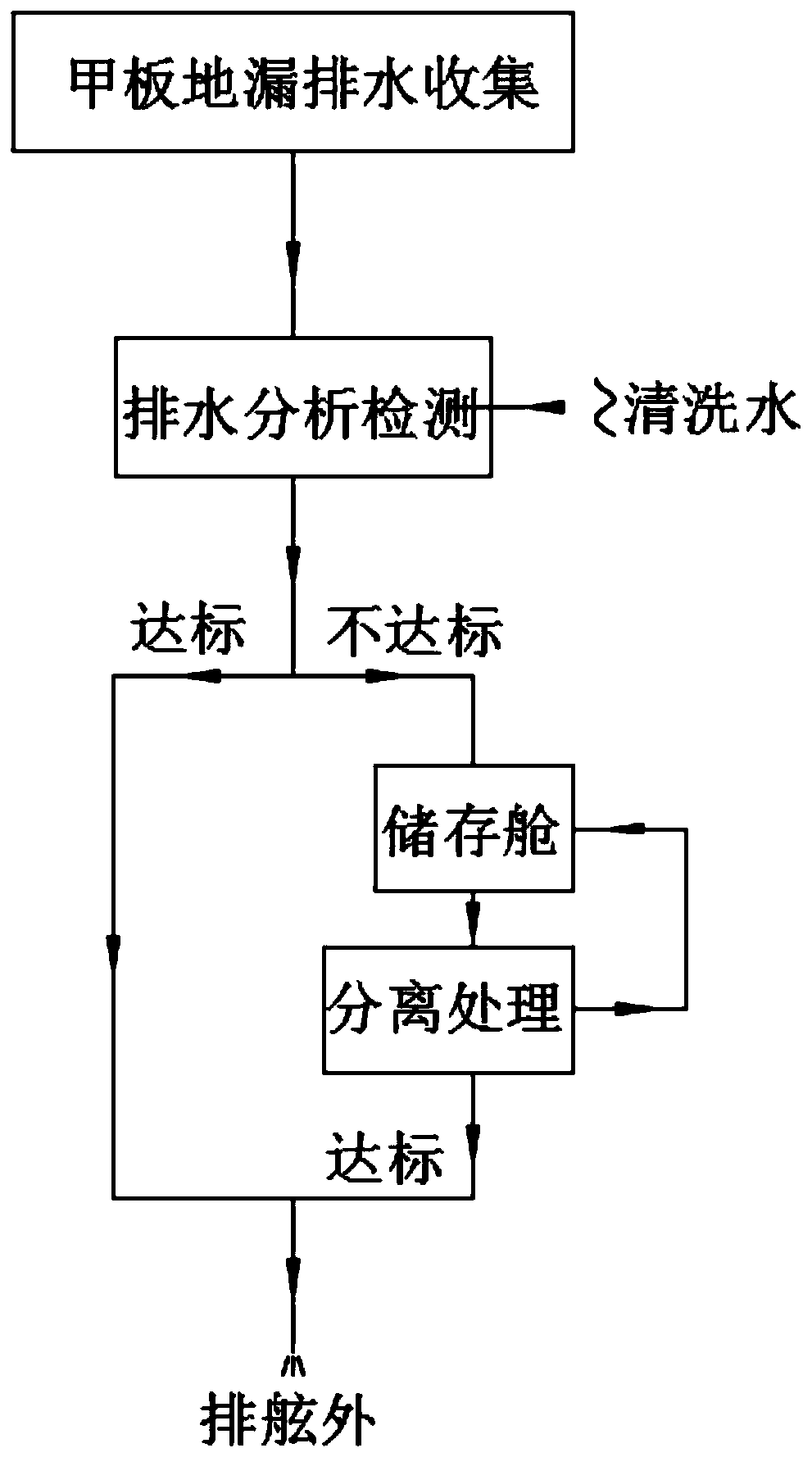

[0019] Such as figure 1 and figure 2 As shown, a kind of ship deck oily sewage treatment system described in this embodiment includes a deck drainage system 1, an oil concentration analyzer 2 and an oily sewage treatment device 3, and the deck drainage system 1 includes a deck drainage system located on the ship deck The several floor drains 11, the several floor drains 11 are connected to the entrance of the drainage main pipe 4 through each drainage branch pipe 12; the oily sewage treatment device 3 includes a sewage collection cabin 31, an oil-water separator 32 and a dirty oil collection cabin 33; The outlet of the main drainage pipe 4 is connected to the outboard 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com