A glass substrate operating platform with a clamping device

A clamping device and glass substrate technology, applied in the direction of electric charge manipulation, transportation and packaging, furnace, etc., can solve the problems of unfavorable operators for glass substrate processing, inconvenient movement of the clamping device, difficult glass substrate stability, etc., to achieve simple structure , Small resistance, easy to move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

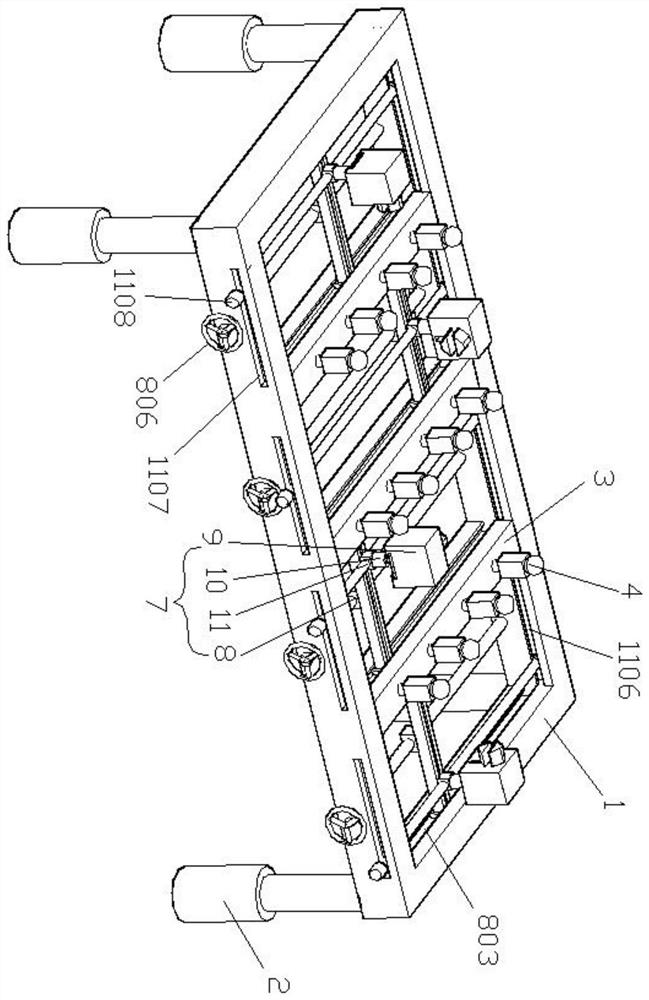

[0033] combine Figure 1-Figure 3 As shown, an operating platform for glass substrate processing;

[0034]The operating platform of the present embodiment includes a roughly rectangular platform frame 1, and the platform frame 1 includes a support leg 2 at the corner of the bottom. In order to facilitate the lifting of the platform frame 1, any support leg 2 is provided with an electric telescopic rod. The rest of the supporting legs 2 are set with auxiliary telescopic rods;

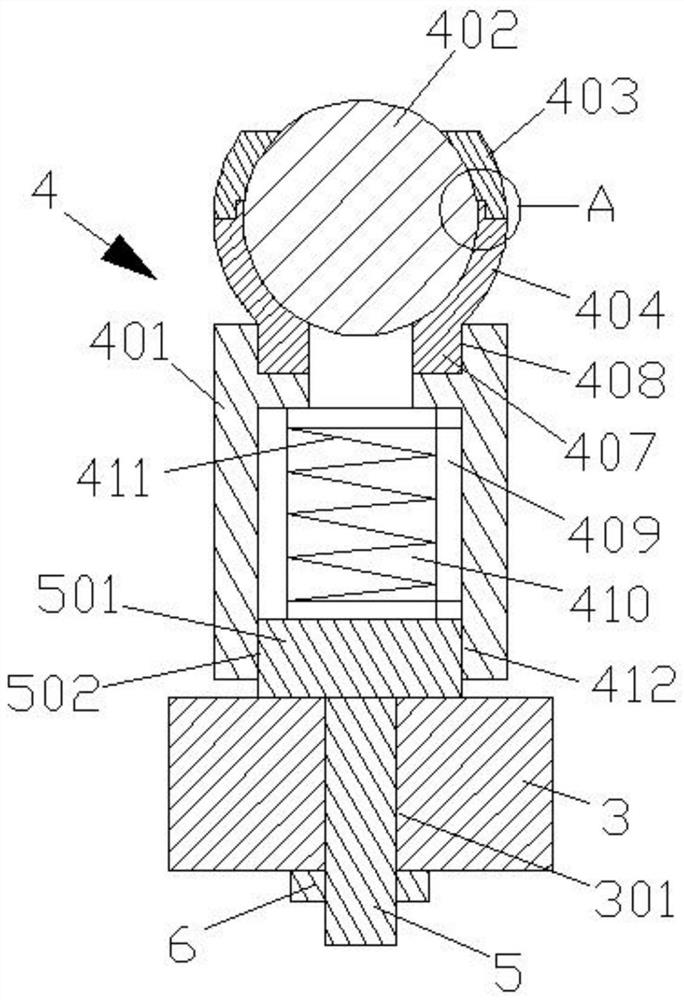

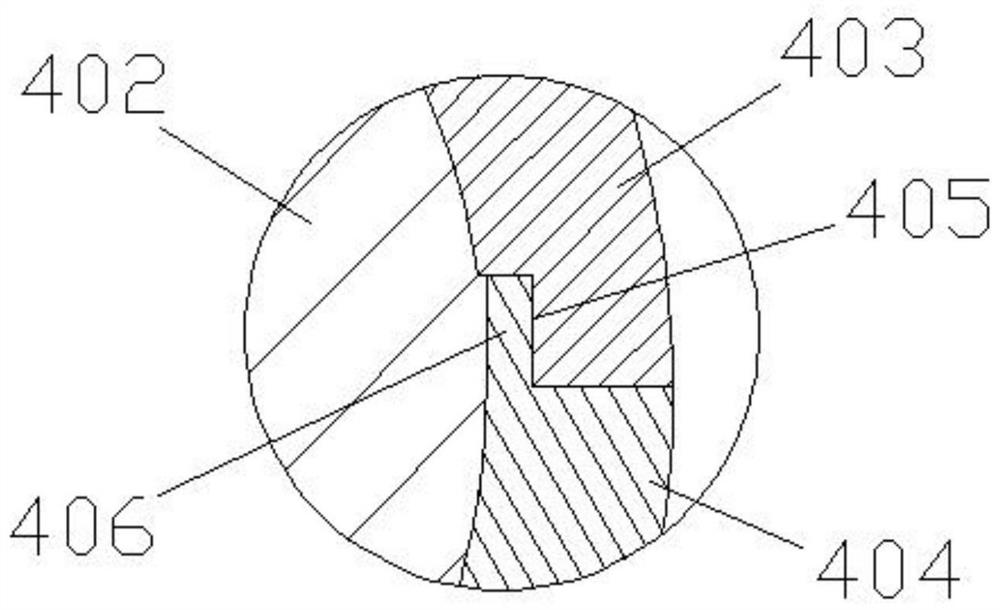

[0035] Three horizontally arranged support rods 3 are welded on the longitudinal position of the above-mentioned platform frame 1, and the spacing between adjacent support rods 3 is the same, and four support columns 4 are detachably installed on each support rod 3, and the support columns 4 include cylinders 401, the bottom of the column body 401 is detachably connected with the bolt 5, and the support rod 3 is provided with a threaded hole 301 that is matched with the body of the above-mentioned bolt ...

Embodiment 2

[0042] The difference between this embodiment and Embodiment 1 is that in this embodiment 2, a clamping device 7 is installed on the platform frame 1, and the clamping device 7 on the platform frame 1 can be firmly clamped by the setting of the clamping device 7, thereby satisfying the requirements of the work. Cutting and edging of glass substrates by personnel;

[0043] In order to achieve the above object, the present embodiment is realized by adding the following structures:

[0044] Such as figure 1 As shown, four clamping devices 7 are installed on the above-mentioned platform frame 1, and the clamping device 7 includes a longitudinal driving mechanism 8, a clamping mechanism 9, a rotating mechanism 10 and a lateral driving mechanism 11;

[0045] combine Figure 4 and Figure 5 As shown, the above-mentioned longitudinal driving mechanism 8 includes a moving rod 801, and the moving rod 801 is movably arranged between the left part of the platform frame 1 and the adjace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com