CL-20/TKX-50 eutectic explosive and production method thereof

A technology of TKX-50 and CL-20, applied in explosives processing equipment, explosives, nitrated acyclic/alicyclic/heterocyclic amine explosive composition, etc., can solve the problem of insignificant desensitization effect and achieve high nitrogen content , low mechanical sensitivity, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

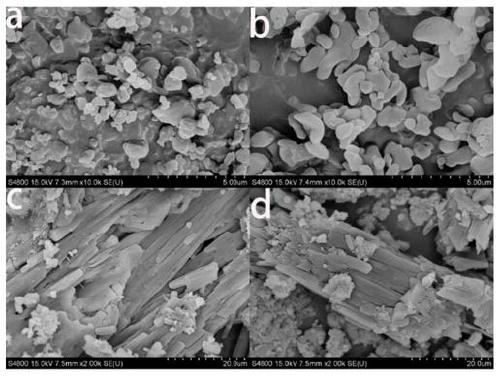

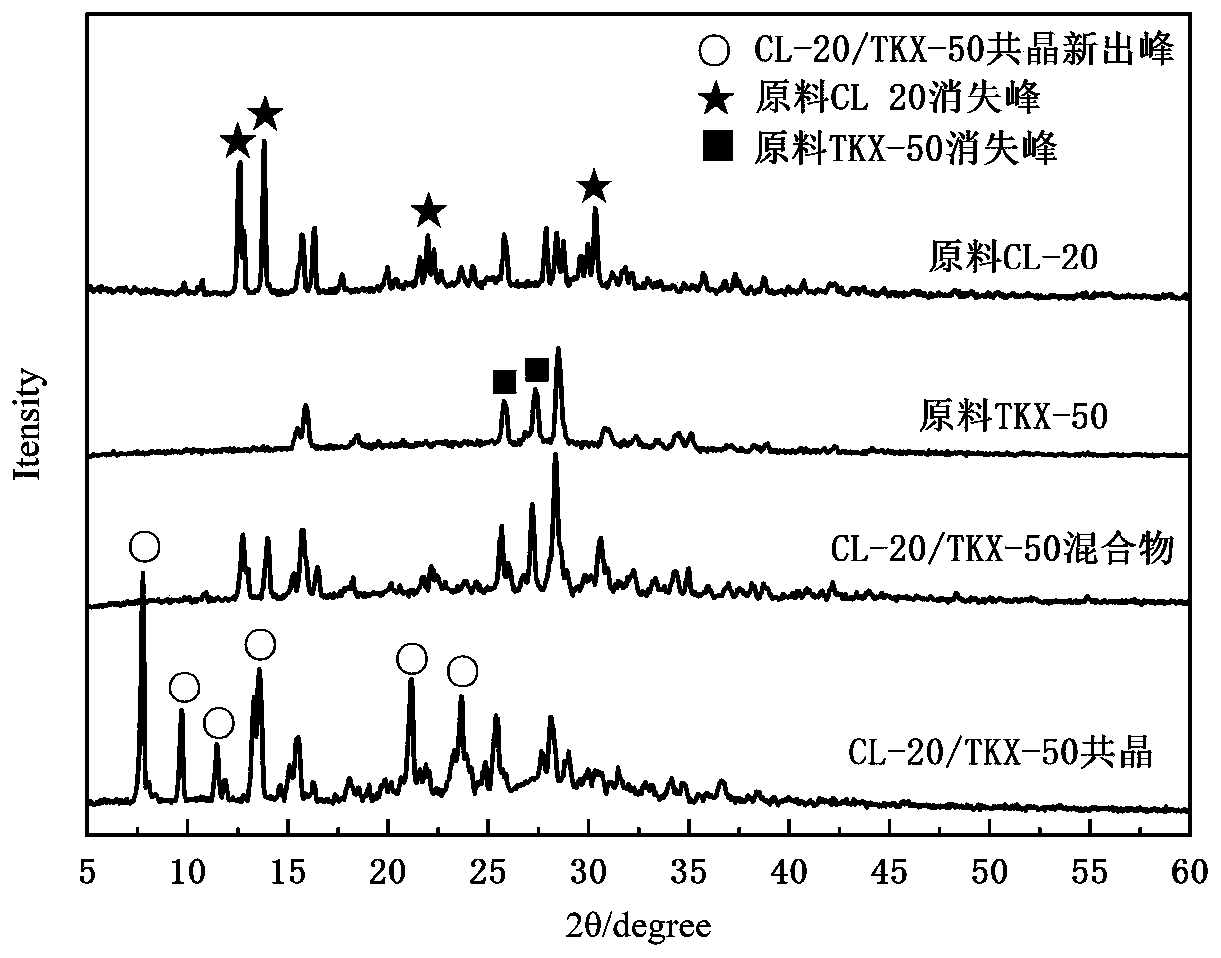

[0026] Example 1: Preparation of eutectic materials of CL-20 and TKX-50 (feeding ratio 1:2)

[0027] Weigh 0.438g (1mmol) of CL-20 and 0.472g (2mmol) of TKX-50 and vacuum dry them in a beaker for 3 hours. Accurately measure 50ml of DMF liquid with a graduated cylinder and add it to the beaker, ultrasonically and heat in a water bath to 80°C until the drug is completely dissolved. Next, measure 80 mL of chloroform in the flask, and drop the completely dissolved solution into the flask at a speed of 0.5 mL / min with a magnetic stirring speed of 1000 rpm. After the dropwise addition, keep stirring at the original speed for 1 h. Finally, after standing for 3 hours, it was filtered, and the filtered sample was vacuum-dried for 3 hours to obtain an ultrafine eutectic sample.

[0028] Test the impact sensitivity of the prepared nanocomposite with reference to method 601.2 in GJB772A-97. In the impact sensitivity experiment, a 5 kg drop hammer was used, the dose of each shot was 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com