Engine coolant compound corrosion inhibitor and preparation method thereof

A technology of engine coolant and composite corrosion inhibitor, which is applied in the field of engine coolant, can solve the problems of not being optimal, unable to adapt to the complex environment of circulating cooling water, etc., achieve good interaction, improve inhibition and protection performance, and corrosion inhibition performance Elevated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

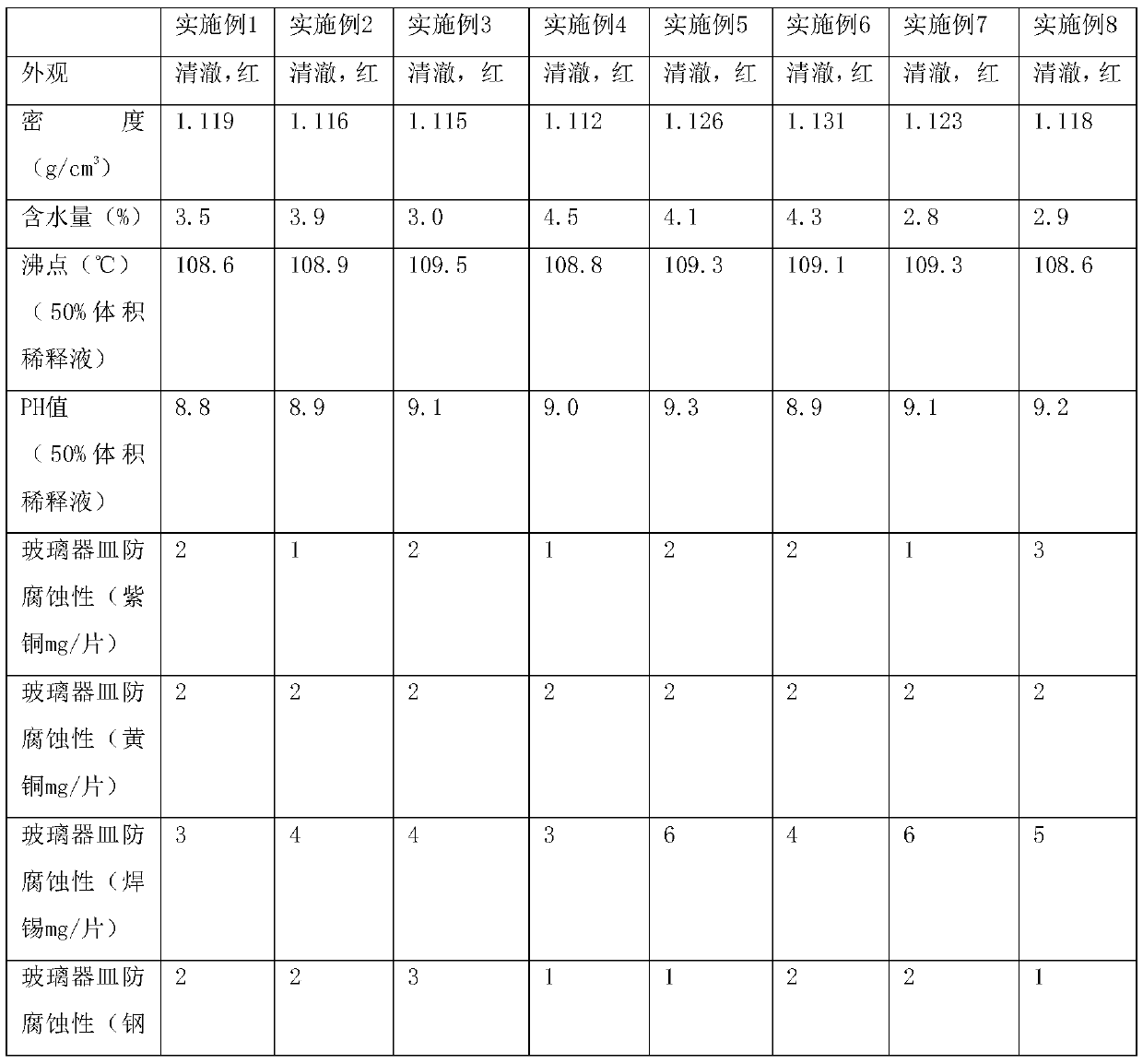

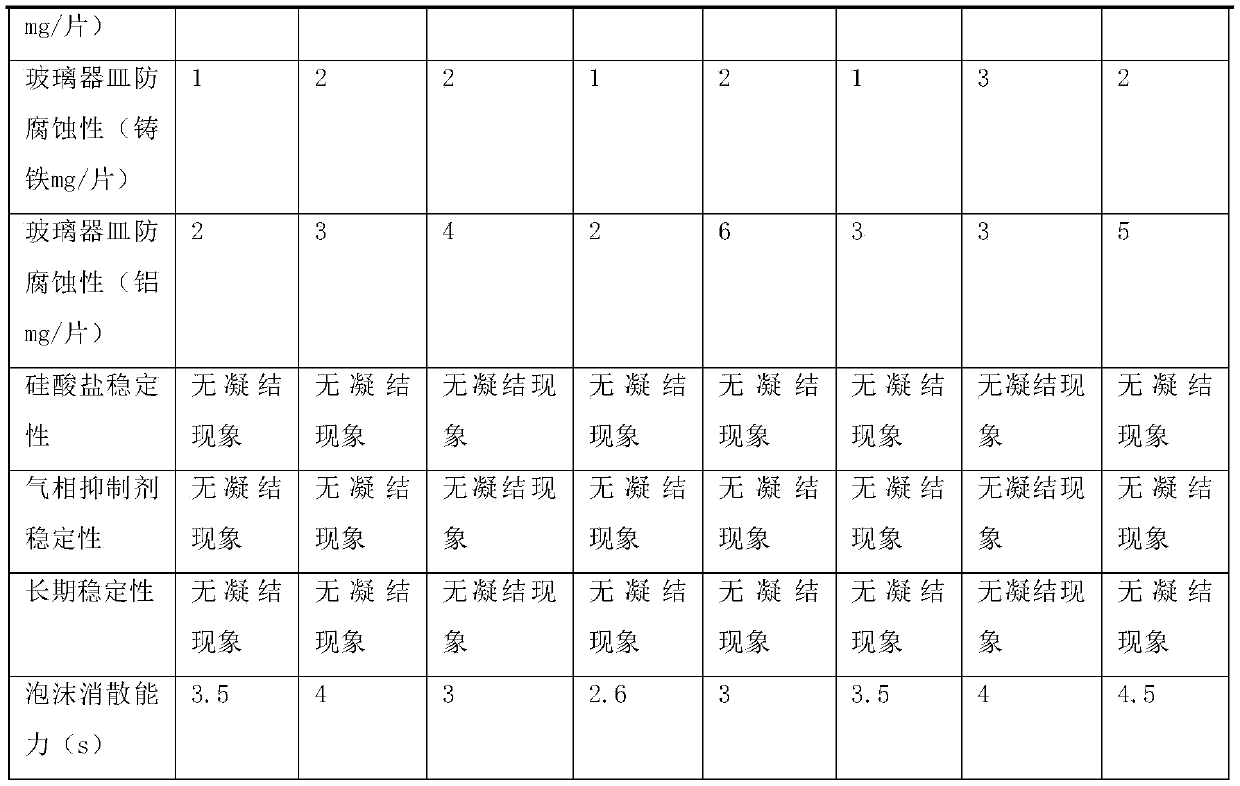

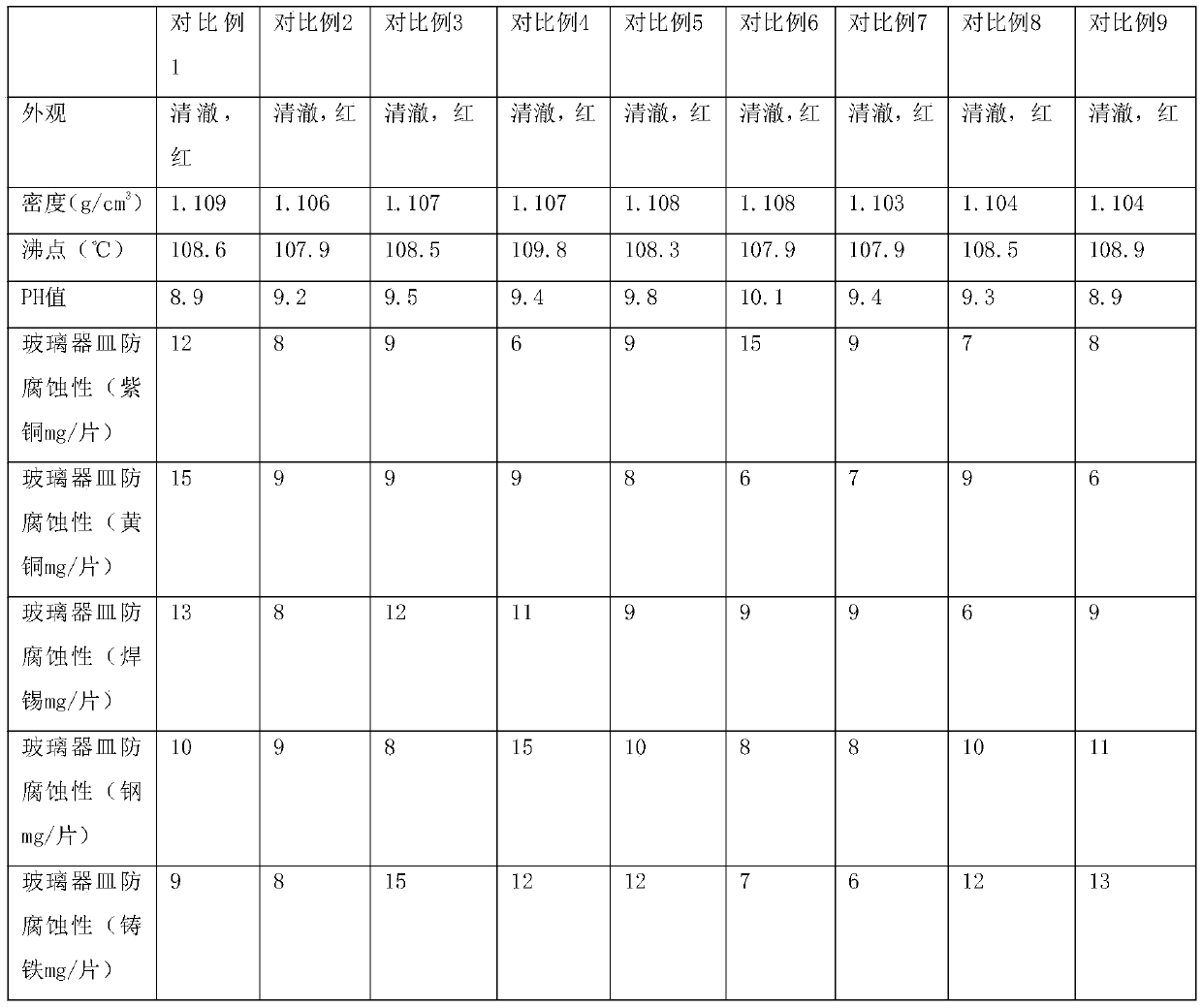

Examples

Embodiment 1

[0019] Mix 50 parts by weight of water and 10 parts by weight of sodium lignosulfonate, and control the mixing temperature in a water bath to 15°C, then add 30 parts by weight of sodium silicate and 2 parts by weight of benzotriazole and mix well , the water bath controls the mixing temperature to 15°C, uses sodium hydroxide to adjust the pH value to 8.5, adds 10 parts by weight of polyacrylamide, 5 parts by weight of silicone, and 5 parts by weight of water-soluble silicone defoamer and mixes evenly. Get a corrosion inhibitor.

Embodiment 2

[0021] Mix 70 parts by weight of water and 20 parts by weight of sodium lignosulfonate, and control the mixing temperature in a water bath to 35°C, then add 50 parts by weight of potassium silicate and 8 parts by weight of benzotriazole and mix well , the water bath controls the mixing temperature to 35°C, uses sodium hydroxide to adjust the pH value to 9.5, adds 20 parts by weight of polyacrylamide, 15 parts by weight of silicone, and 15 parts by weight of glyceryl ether and mixes evenly to obtain corrosion inhibition agent.

Embodiment 3

[0023] Mix 60 parts by weight of water and 15 parts by weight of sodium lignosulfonate, and control the mixing temperature in a water bath to 25°C, then add 40 parts by weight of sodium silicate and 5 parts by weight of benzotriazole and mix well , the water bath controls the mixing temperature to 25°C, uses sodium hydroxide to adjust the pH value to 9.0, adds 15 parts by weight of polyacrylamide, 10 parts by weight of silicone, and 10 parts by weight of water-soluble silicone defoamer and mixes evenly. Get a corrosion inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com