Carbon dioxide-based copolymer foamed plastic and preparation method thereof

A technology of carbon dioxide and foam plastics, applied in the field of biodegradable foam plastics, can solve the problems of narrow processing window, poor thermal stability, and low expansion ratio, and achieve broad application prospects, good foaming performance, and good interaction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a method for preparing the carbon dioxide-based copolymer foam described in the above technical scheme, comprising the following steps:

[0042] a) mixing carbon dioxide-epoxycyclohexane copolymer, carbon dioxide-propylene oxide copolymer, toughening agent and transesterification agent and then granulating to obtain plastic particles;

[0043] b) placing the plastic particles obtained in step a) in 3MPa-8MPa carbon dioxide for reaction, and then undergoing pressure relief treatment and cooling to obtain a carbon dioxide-based copolymer plastic foam.

[0044] In the invention, the carbon dioxide-epoxy cyclohexane copolymer, the carbon dioxide-propylene oxide copolymer, the toughening agent and the transesterification agent are mixed and then granulated to obtain plastic granules. In the present invention, the carbon dioxide-epoxycyclohexane copolymer, carbon dioxide-propylene oxide copolymer, toughening agent and transesterification ag...

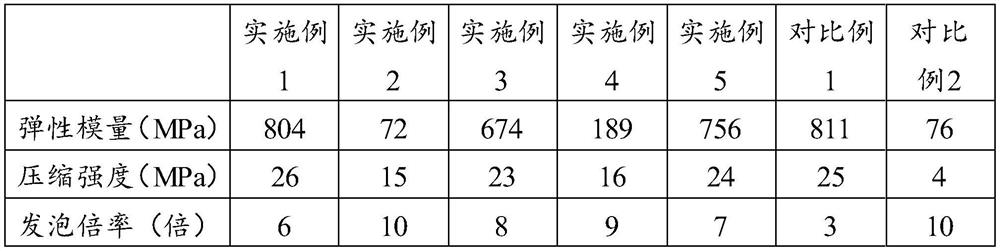

Embodiment 1

[0062] (1) 1 kg of PCHC with a number average molecular weight of 60 kg / mol and a molecular weight distribution of 2.8, 0.05 kg of PPC with a number average molecular weight of 150 kg / mol and a molecular weight distribution of 2.6, 0.1 kg of ethylene-octene copolymer and 10 g of tetra-n-butyl titanate The ester is uniformly mixed in a mixer, and then the obtained mixture is fed into a twin-screw granulator for granulation to obtain plastic granules.

[0063] (2) Place the plastic granules obtained in step (1) in an autoclave, fill the autoclave with 5MPa of carbon dioxide, heat the autoclave to 110°C, keep the temperature and pressure for 60min, and then The pressure inside the autoclave was released at a speed of 5 MPa / s, and finally the autoclave was cooled to 25° C. to obtain a carbon dioxide-based copolymer plastic foam.

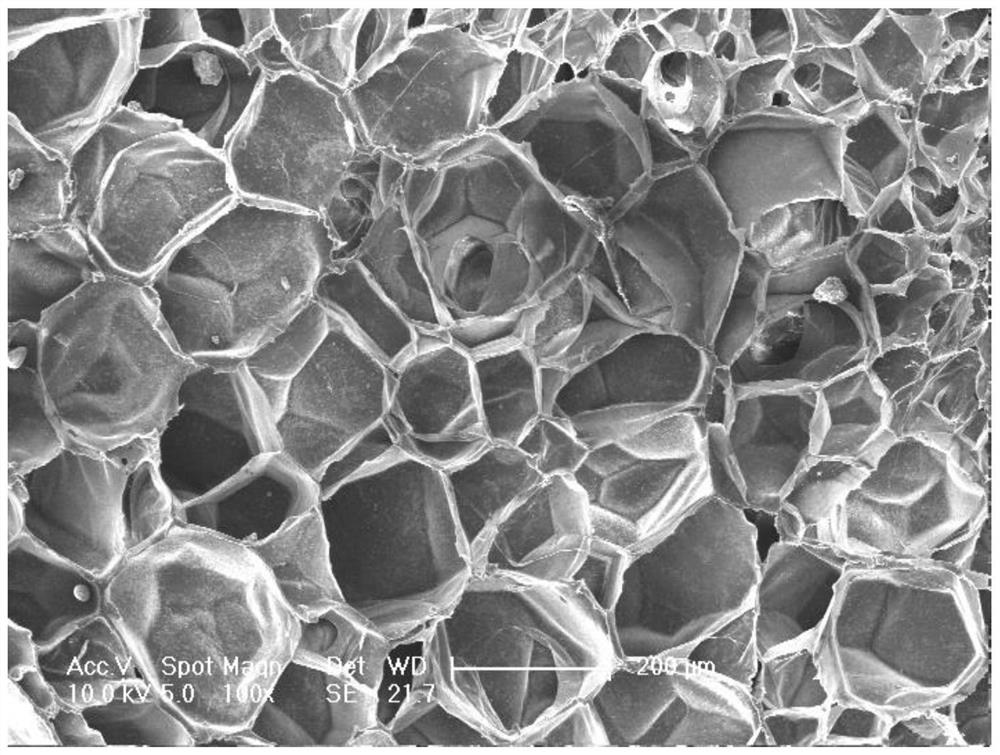

[0064] The carbon dioxide base copolymer foam that the embodiment of the present invention 1 obtains is carried out scanning electron microscope test, a...

Embodiment 2

[0067] (1) 1 kg of PCHC with a number average molecular weight of 40 kg / mol and molecular weight distribution of 3, 0.3 kg of PPC with a number average molecular weight of 80 kg / mol and a molecular weight distribution of 2.2, 0.2 kg of ethylene-octene copolymer and 10 g of tetra-n-butyl titanate The ester is uniformly mixed in a mixer, and then the obtained mixture is fed into a twin-screw granulator for granulation to obtain plastic granules.

[0068] (2) Place the plastic granules obtained in step (1) in an autoclave, fill the autoclave with 5MPa of carbon dioxide, heat the autoclave to 100°C, keep the temperature and pressure for 180min, and then The pressure inside the autoclave was released at a speed of 5 MPa / s, and finally the autoclave was cooled to 25° C. to obtain a carbon dioxide-based copolymer plastic foam.

[0069] After testing, the expansion ratio, elastic modulus and compressive strength data of the carbon dioxide-based copolymer foam prepared in Example 2 of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com