Friction plate

A friction plate and friction material technology, applied in the direction of friction linings, friction clutches, clutches, etc., can solve many problems such as torque transmission, and achieve the effect of reducing resistance torque, improving cooling performance, and improving cooling performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

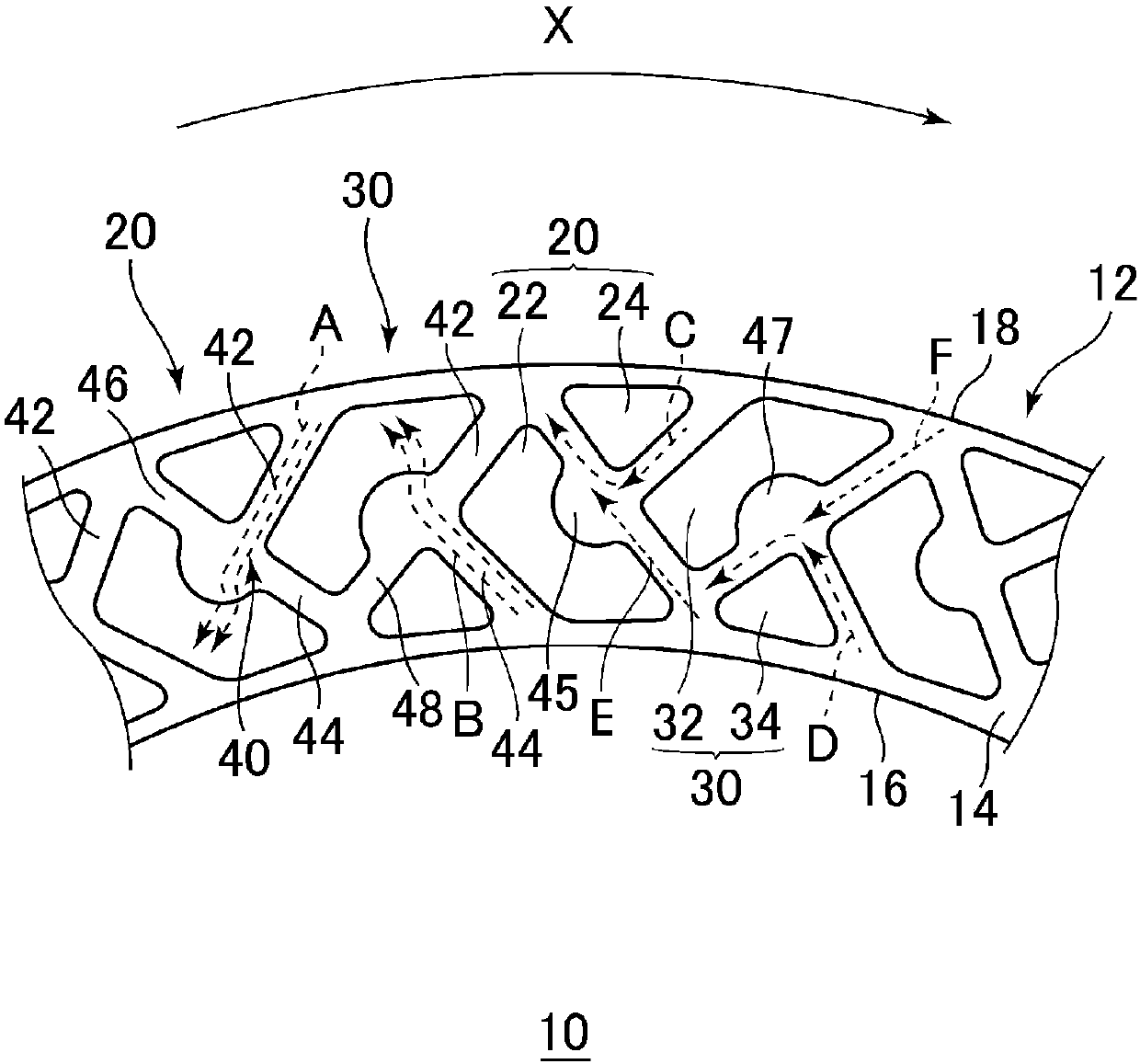

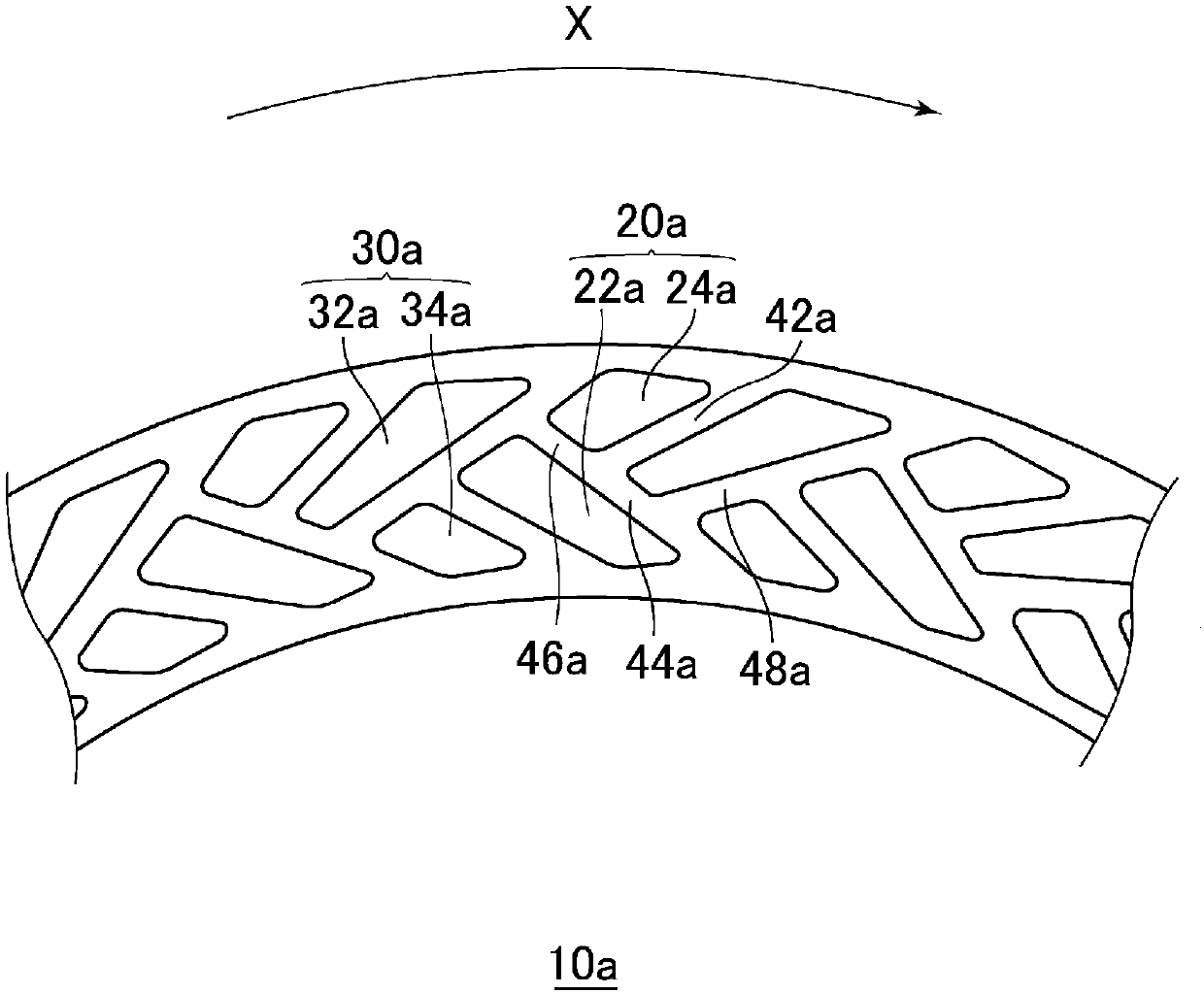

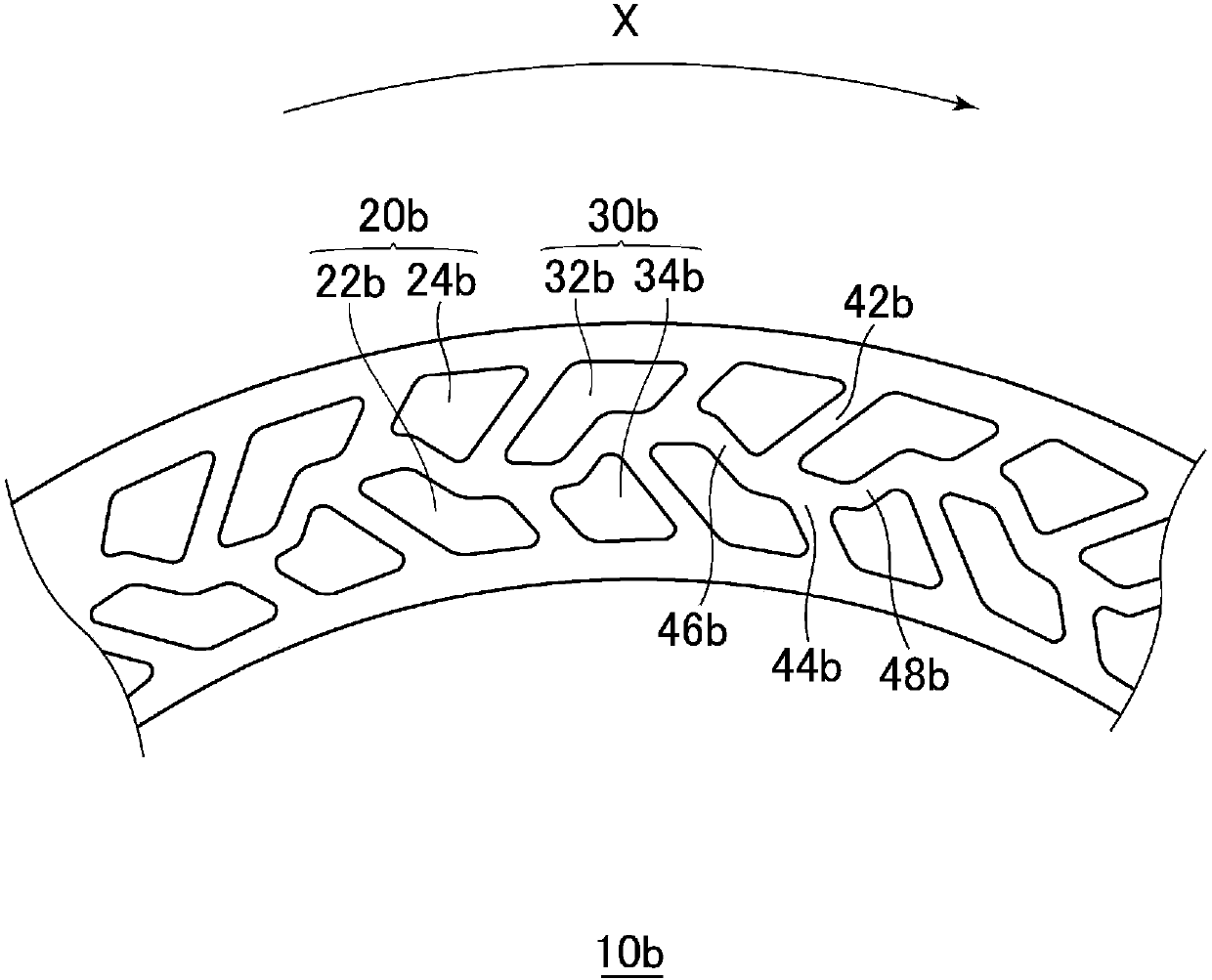

[0049] Below, refer to the attached Figure 1~3 Embodiments of the present invention will be described. However, the present invention is not limited to these embodiments. In addition, although the friction plate of this invention is used for a friction clutch, since the basic structure of a friction clutch is well-known, description accompanying illustration of a friction clutch itself is abbreviate|omitted.

[0050] Such as figure 1 As shown, in the friction plate 10 of the present invention, on the surface 14 of the plate 12, the first friction material group 20 and the second friction material group 30 are attached alternately in the circumferential direction, and the first friction material group 20 consists of a pair of opposite The first segment 22 located on the inner peripheral side and the second segment 24 located on the outer peripheral side, the second friction material group 30 is composed of a pair of third segment 32 located on the outer peripheral side and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com