Wind power blade defect identification method

A wind power blade and defect identification technology, applied in neural learning methods, instruments, biological neural network models, etc., can solve problems such as low efficiency, large workload, and complex blade ultrasonic signals, achieve high automatic recognition rate, and avoid subjective errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further specifically described below in conjunction with the accompanying drawings and embodiments.

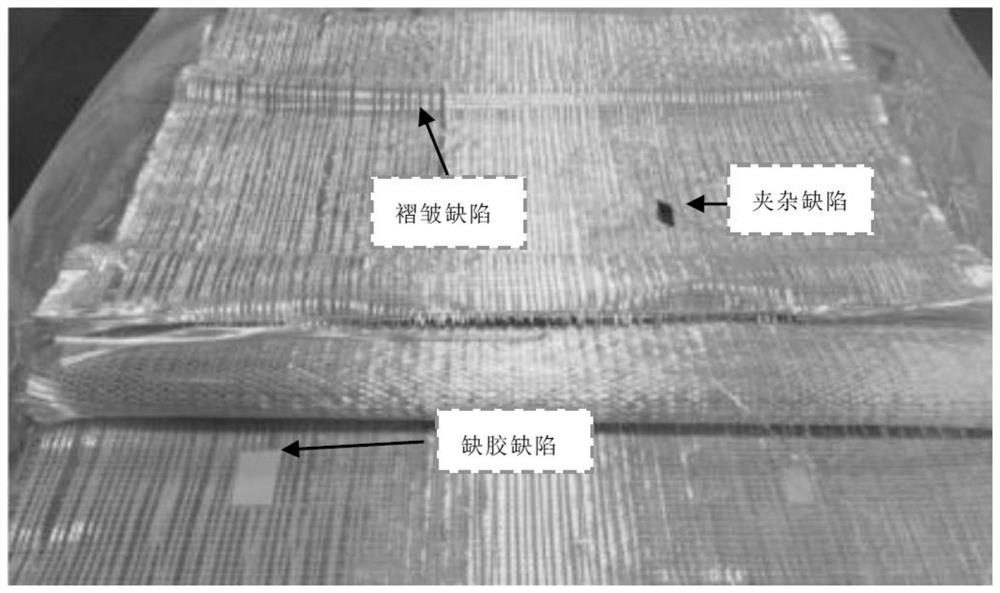

[0030] figure 1 For the prefabricated wind turbine blade samples containing defects (glass fiber cloth is glass fiber cloth) for this embodiment, the preset defect types are wrinkles, lack of glue and inclusions, and the specific defect parameters are shown in Table 1. The wind turbine blades used are made of glass fiber cloth and epoxy resin, and are formed by vacuum injection technology. The manufacturing process is to lay a layer of glass fiber and then a layer of epoxy resin. There are 37 layers in total. The first layer And the 37th layer is glass fiber cloth, and its molding thickness is 1.2mm per layer, 44.4mm in total. Three types of defects including inclusions, lack of glue and wrinkles were prefabricated in the sample, that is, the wrinkles were formed by pre-embedding cylindrical FRP between the 17th and 18th layers of glass fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com