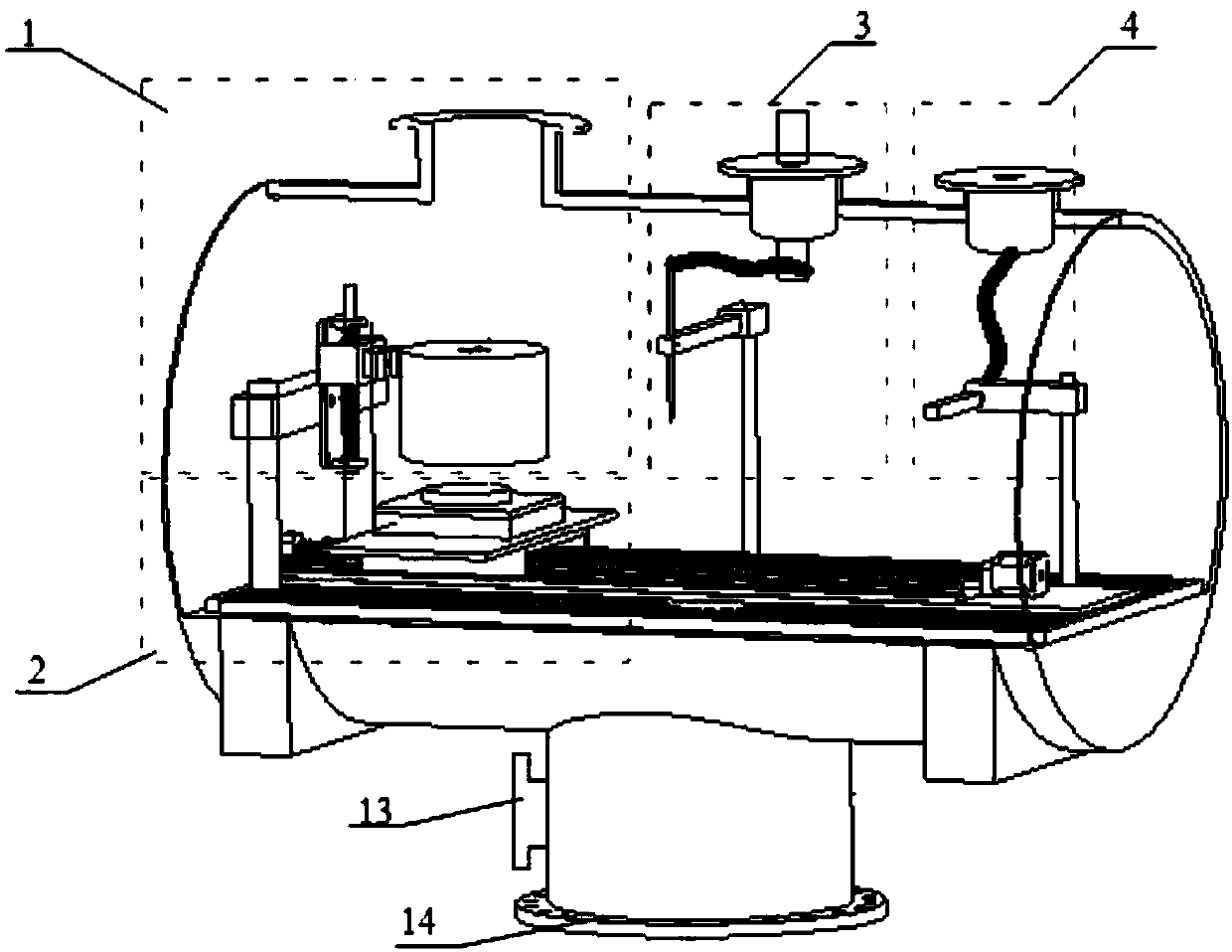

Integrated measuring device for surface dielectric properties of solid insulating materials

A technology of solid insulating materials and dielectric properties, applied in measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve the problem that the secondary electron emission characteristics of materials cannot be measured, and the surface of insulating materials cannot be truly and comprehensively reflected Dielectric properties, inability to measure secondary electron emission characteristics of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

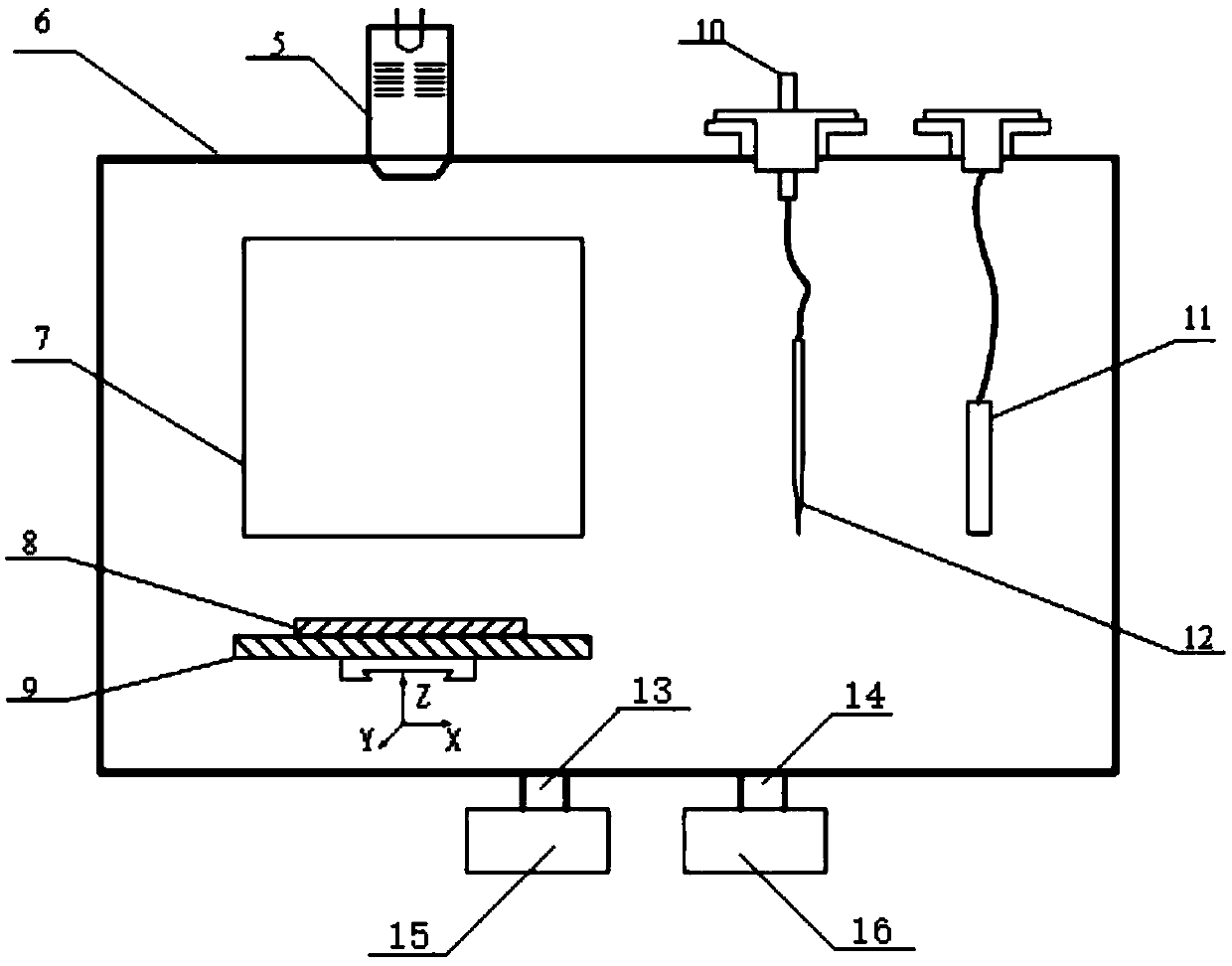

[0044] Secondary electron emission coefficient, surface charge and charge trap measurement steps in high vacuum environment:

[0045] 1) Place the sample 8 on the sample stage 9, set the temperature of the sample stage 9, evacuate the external cavity 6, and heat the sample 8 to the specified temperature.

[0046] 2) Move the sample stage 9 to below the collector 7, set the electron beam energy and beam current I of the electron gun 5 P , the electron beam bombards the surface of the material, and the secondary electron collector 7 collects the secondary current I SE , according to the secondary electron emission coefficient σ=I SE / I P Calculate the secondary electron emission coefficient.

[0047] 3) Using the electron gun 5 to charge the sample.

[0048] 4) After charging is completed, move the sample stage 9 to the bottom of the electrostatic probe 11 of the surface potential measurement module 4, measure the distribution of the surface potential of the sample 8, and ob...

Embodiment 2

[0051] Surface potential and charge trap measurement steps in high pressure environment:

[0052] 1) First place the sample 8 on the sample stage 9, set the temperature of the sample stage 9, and heat the sample 8 to the specified temperature.

[0053] 2) The sample stage 9 is moved to the bottom of the corona needle 12, and the outer cavity 6 is evacuated and filled with working gas to a certain pressure.

[0054] 3) Applying a certain voltage to the corona needle 12, keeping a certain distance from the surface of the sample 8, injecting charges into the sample 8.

[0055] 4) Move the sample stage 9 to the bottom of the electrostatic probe 11 of the surface potential measurement module 4 to measure the surface potential decay curve of the sample 8, obtain the surface charge distribution characteristics and calculate the material charge trap parameters through the surface potential decay curve.

[0056] 5) After the corona charging module charges the sample, quickly cool the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com