Method for evaluating bearing capacity of overhead steel-cored aluminum stranded wire after mountain fire fumigation

A steel-cored aluminum stranded wire, bearing capacity technology, applied in the direction of tension measurement, special data processing applications, instruments, etc., can solve problems such as potential safety hazards in power transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

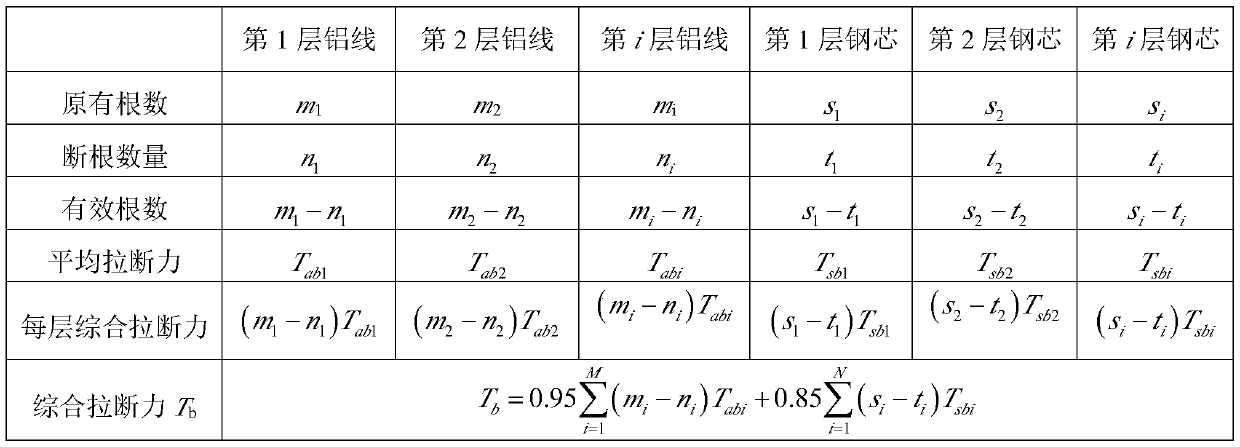

[0117] (1) Assume that an overhead conductor whose model is JL / G1A-400 / 50 is roasted by a mountain fire at 200°C, and one conductor with serious burns breaks 2 aluminum wires on the first layer, and 1 aluminum wire on the second layer. root, 3rd layer aluminum wire and steel core intact. Purchase the signal wire and fill in the number of effective experimental monofilament wires in each layer according to the site as shown in Table 3. Then carry out the resistance furnace baking test, the test temperature is 300 ℃, and the time is 30 minutes. Finally, the tensile force test of the aluminum layer and the steel core is carried out separately by using a universal material testing machine, and the parameters of the tensile force of each layer of monofilament conductor can be obtained. Finally, the comprehensive breaking force T is calculated b :

[0118] Table 3 The overhead wires of JL / G1A-400 / 50 are roasted in a resistance furnace at 300°C

[0119]

[0120] (2) Consult th...

Embodiment 2

[0126] (1) Assume that an overhead conductor whose model is JL / G1A-500 / 45 is roasted by a mountain fire at 400°C, and one conductor with serious burns breaks 4 aluminum wires on the first layer, and 2 aluminum wires on the second layer. 1 root, and 1 aluminum wire on the third layer was broken. The steel core is not broken. Purchase the signal wire and fill in the number of effective experimental monofilament wires in each layer according to the site as shown in Table 5. Then carry out the resistance furnace baking test, the test temperature is 300 ℃, and the time is 30 minutes. Finally, the tensile force test of the aluminum layer and the steel core is carried out separately by using a universal material testing machine, and the parameters of the tensile force of each layer of monofilament conductor can be obtained. Finally, the comprehensive breaking force T is calculated b :

[0127] Table 5 The overhead wire of JL / G1A-500 / 45 is roasted in a resistance furnace at 400°C ...

Embodiment 3

[0135] (1) Assume that an overhead conductor whose model is JL / G1A-800 / 70 is roasted by a mountain fire at 550°C, and one conductor with serious burns breaks 8 aluminum wires on the first layer and 5 aluminum wires on the second layer. Three aluminum wires on the third layer were broken, two steel cores on the first layer were broken, and the steel core on the second layer was intact. Purchase the signal wire and fill in the number of effective experimental monofilament wires in each layer according to the site as shown in Table 7. Then carry out the resistance furnace baking test, the test temperature is 550 ℃, and the time is 30 minutes. Finally, the tensile force test of the aluminum layer and the steel core is carried out separately by using a universal material testing machine, and the parameters of the tensile force of each layer of monofilament conductor can be obtained. Finally, the comprehensive breaking force T is calculatedb :

[0136] Table 7 The overhead wires o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com