Method for promoting in-vitro and in-vivo degradation and cell extension adherence of alginate-based 3D printed bioink

A technology of alginate and bio-ink, applied in biochemical equipment and methods, animal cells, vertebrate cells, etc., can solve the problems of alginate limitations and achieve the effect of promoting adhesion, changing porosity and compressive modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

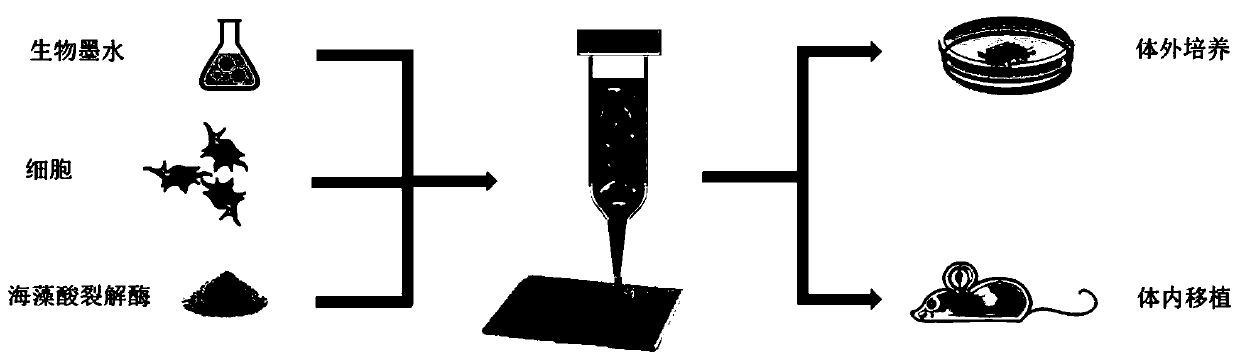

[0044] Example 1: Using alginate lyase to promote the in vivo and in vitro degradation of alginate-based bio-3D printing blocks.

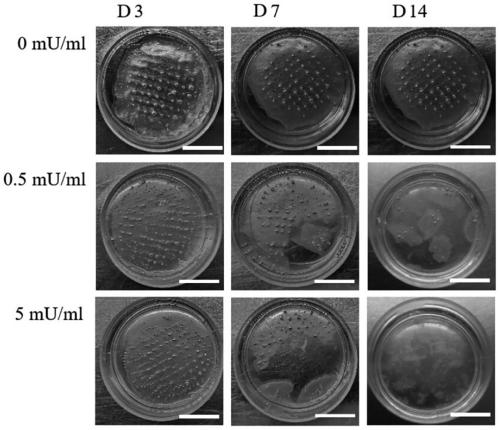

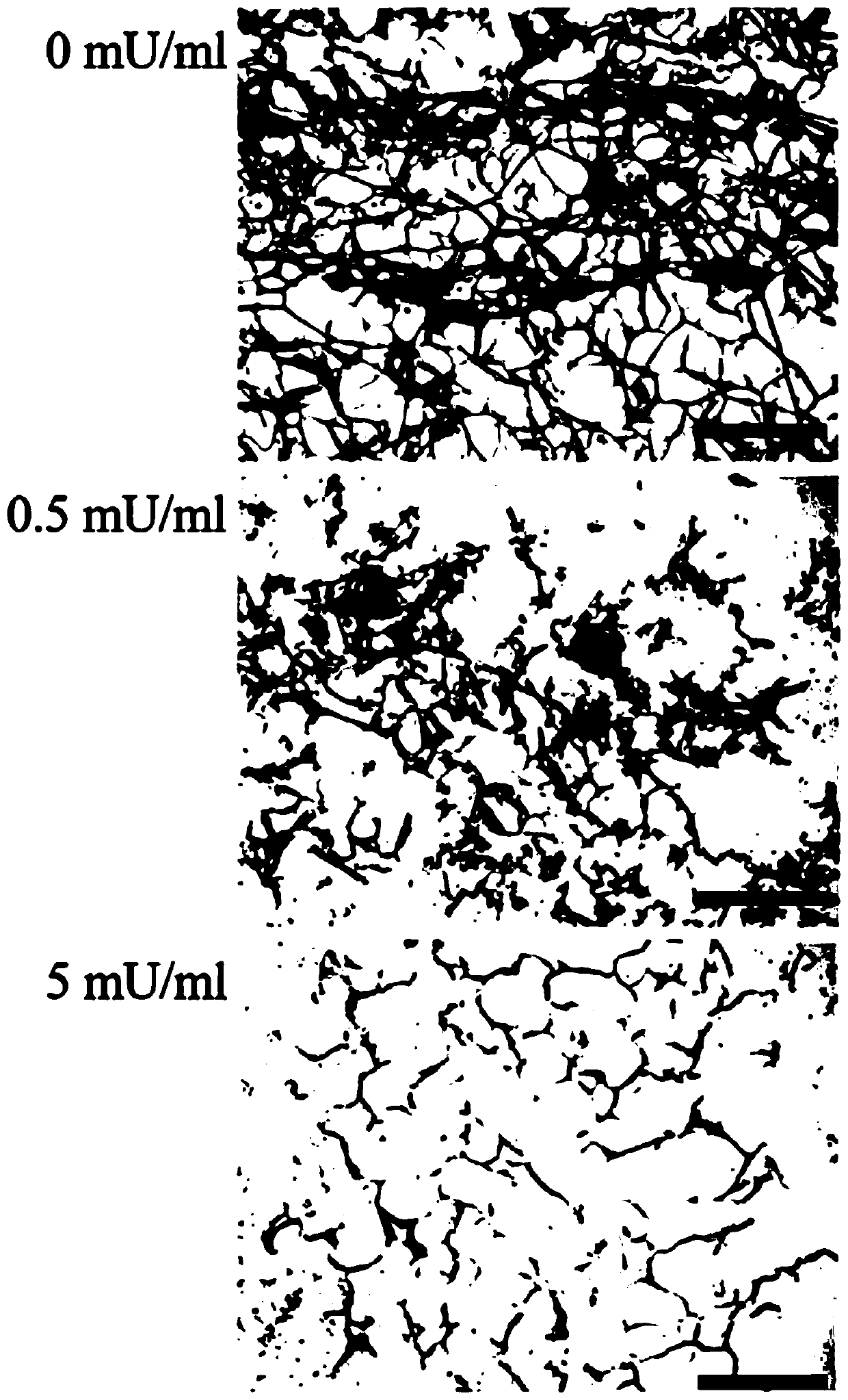

[0045] Alginate / gelatin-mixed bioink using alginate lyase, as shown in Figure 2 and Figure 3, Figure 2APrints cultured in vitro can be observed, and the degradation time is correlated with the alginate lyase concentration. Figure 2B Printed blocks with different concentrations of sodium alginate lyase, H&E staining results, the shaded part is alginate, and the fragmentation degree of alginate skeleton is significantly different with the change of enzyme concentration (scale bar: 200 μm). Such as Figure 3B As shown, the mouse dermal fibroblasts with DiI fluorescent signal were mixed into the bio-ink, and the printed block was implanted subcutaneously in nude mice, and traced detection was carried out using a living small animal instrument. Figure 3A Shown is the result of sampling tissue sections after the print blocks were implanted subcutane...

Embodiment 2

[0058] Example 2: Using alginate lyase to promote cell expansion and migration in alginate-based bio-3D printing blocks.

[0059] Under physiological conditions, cells are generally polygonal and have the characteristics of stretching and adhesion. Conventional alginate lacks cell attachment sites, and although it has good biocompatibility, cells stretch less in alginate print blocks. Using alginate lyase, as shown in Figure 4, can significantly increase cell stretching in the printed block. Such as Figure 4A As shown, in the print block without adding alginate lyase, most of the cells were oval, and in the print block added with alginate lyase, the formation of cell pseudopodia and cell extension could be observed (scale bar: 50 μm). Figure 4B This is the state of GFP fluorescent mouse dermal fibroblasts in alginate-based bioink. In the print block added with alginate lyase, the proportion of cell extension to the total cells was significantly increased, and the ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com