Brush synchronous belt, belt body drilling device and processing method of brush synchronous belt

A synchronous belt and brush technology, applied in the production and processing field of synchronous belts, can solve the problems of reduced transmission reliability, scratch marks on the surface, interruption of anti-friction material transmission, etc., and achieve the effect of neat and beautiful products, smooth bristles, and reliable fixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

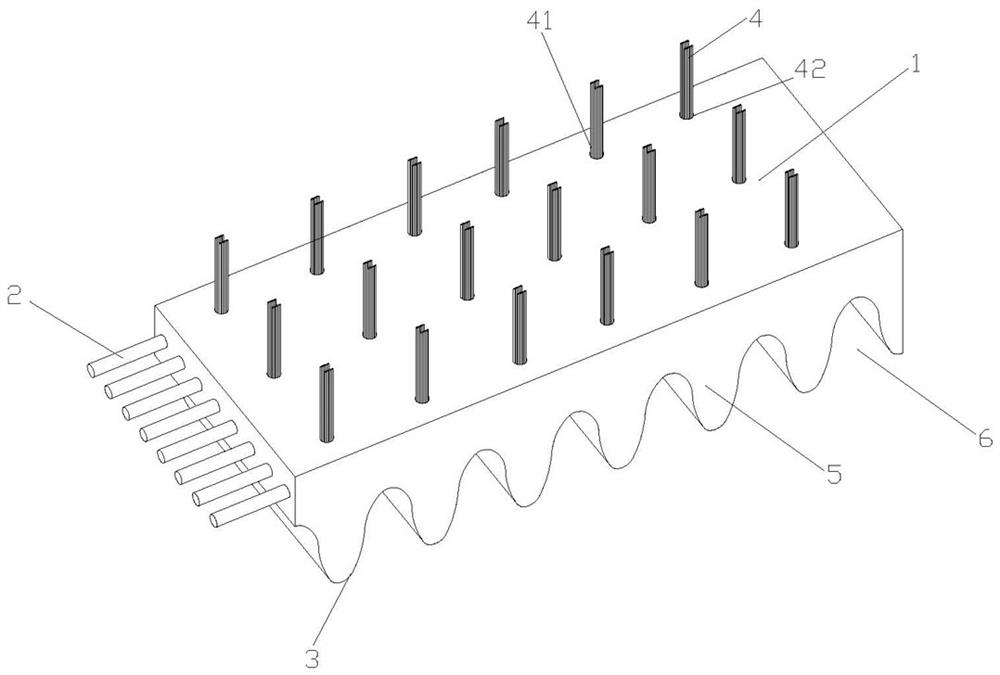

[0030] The brush synchronous belt of the present invention includes a synchronous belt body 1 , and is characterized in that: the synchronous belt body 1 is provided with a brush 4 .

[0031] As a preferred solution of the present invention, a skeleton rope 2 is arranged inside the belt body 1 , and a cloth belt 3 is arranged on the surface of the protruding teeth 5 and the concave teeth 6 of the belt body 1 . While improving the wear resistance of the synchronous belt teeth, the meshing noise of the synchronous belt and pulley transmission is reduced.

[0032] Further, the belt body 1 is made of antistatic polyurethane material, and the brush 4 is made of antistatic nylon brush wire 41 .

[0033] As another preferred solution of the present invention, the belt body 1 is an integral seamless endless belt, and the skeleton rope 2 in the belt body 1 is continuously and uniformly wound. The transmission reliability and service life of the polyurethane synchronous belt are greatl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com