Method for operating spinning device of rotor spinning machine and spinning device of rotor spinning machine

The technology of rotor spinning machine and rotor cup is applied in one field of spinning device, which can solve the problems of inhaling impurities and the like, and achieve the effect of reducing dirt and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

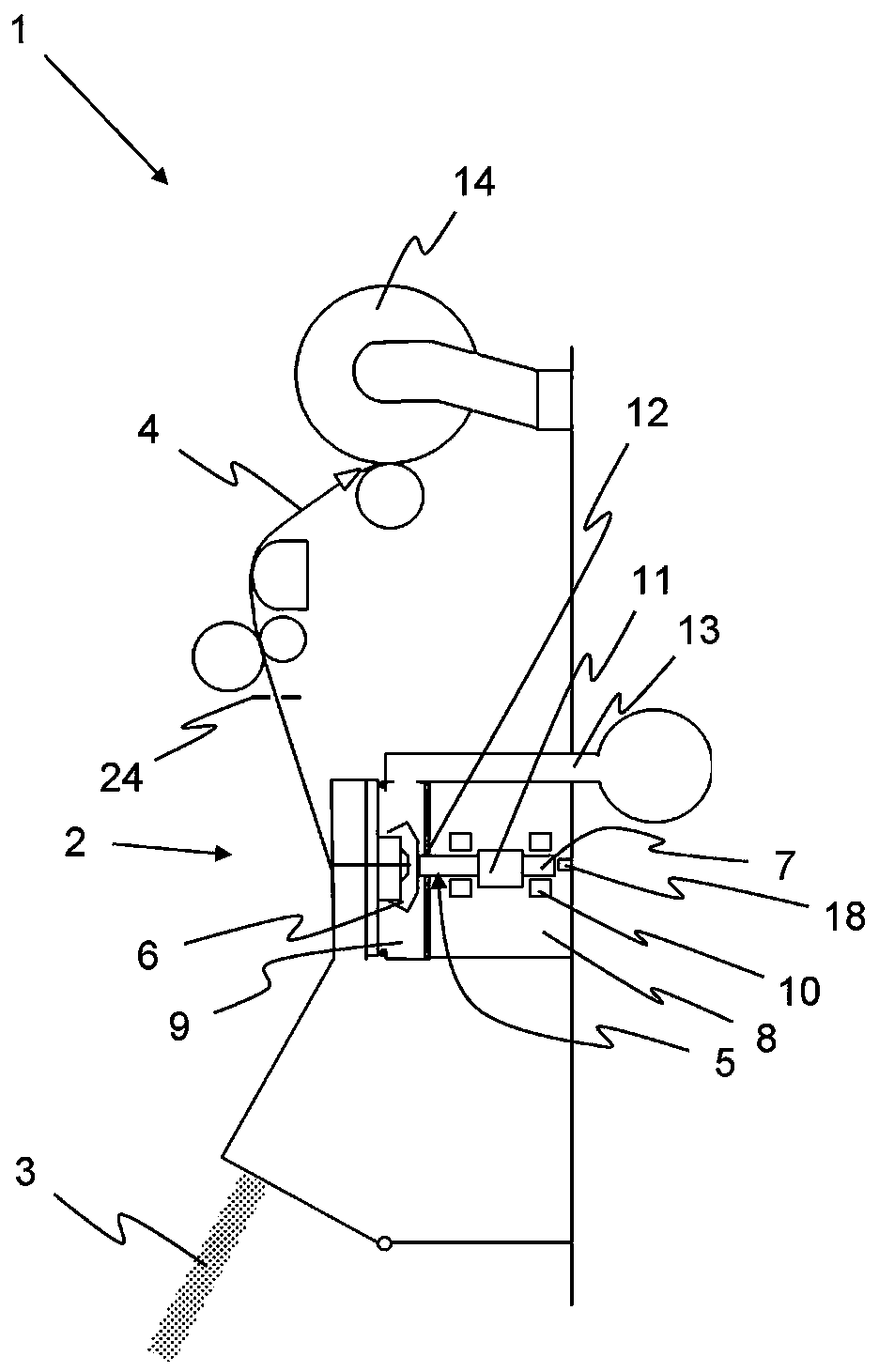

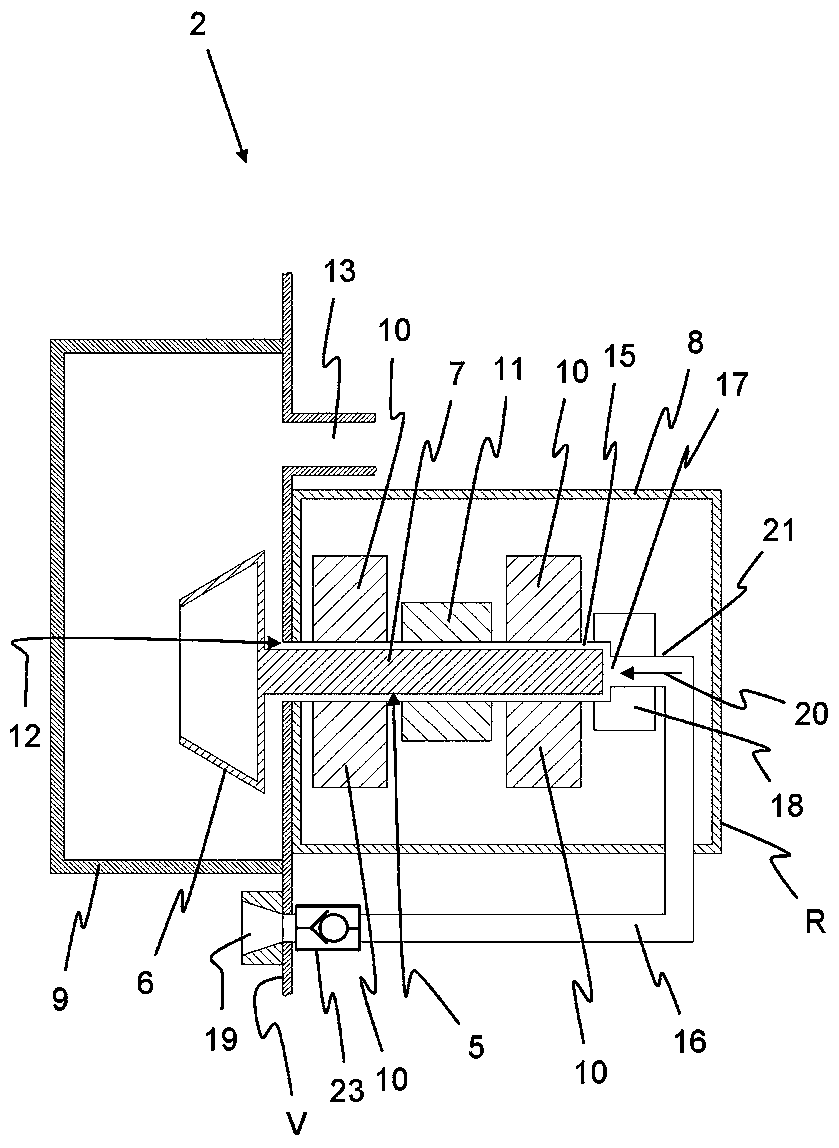

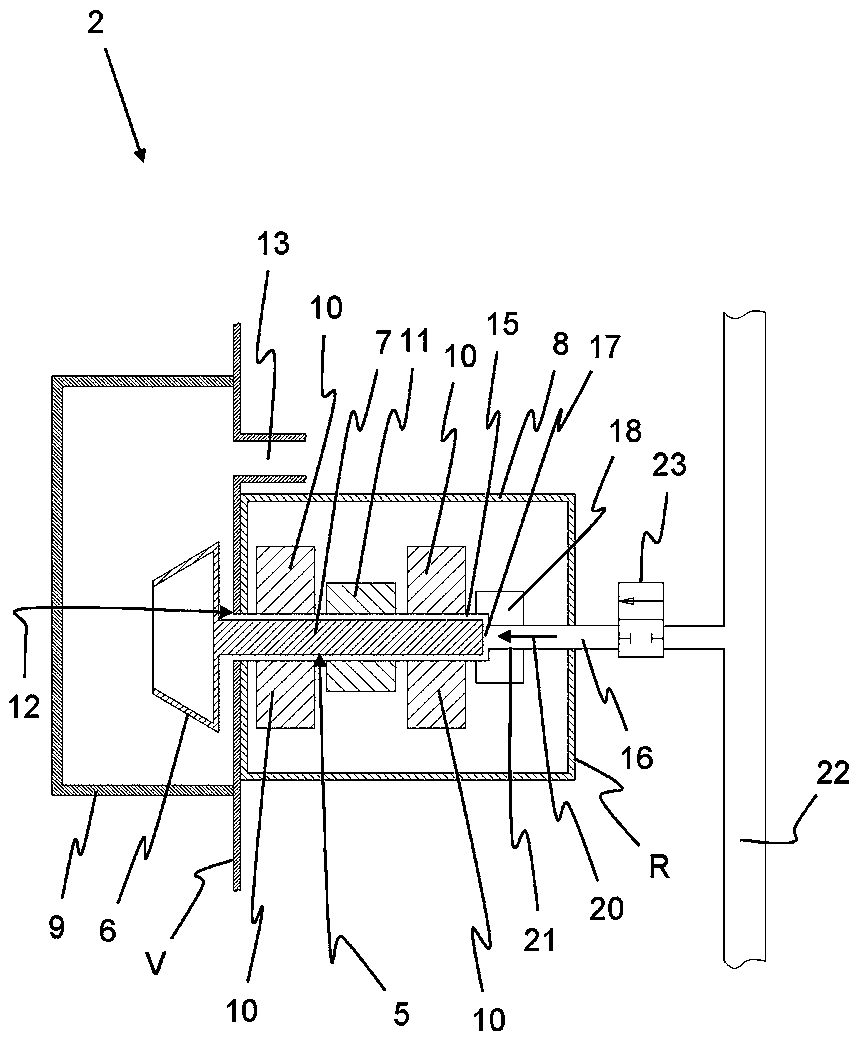

[0073] figure 1 A schematic side view of a rotor spinning machine 1 with a spinning device 2 is shown. With the aid of the spinning device 2 , a yarn 4 can be spun from the fiber material 3 , which yarn can be wound up on a drum 14 . The spinning device 2 has a spinning rotor 5 by means of which a yarn 4 is formed from a fiber material 3 during operation of the rotor spinning machine 1 .

[0074] The spinning rotor 5 has a rotor cup 6 and a rotor shaft 7 . In order to form the yarn 4 from the fiber material 3 , the fiber material is guided into the rotor cup 6 during the rotation of the spinning rotor 5 . By means of the rotation of the spinning rotor 5, the yarn 4 is formed. The spinning rotor 5 can be driven here by a drive 11 which is designed in particular as an electromechanical single drive. The rotational speed of the spinning rotor 5 can be counted here as 150,000 1 / min or higher, so that high demands are placed on the bearing 10 of the spinning rotor 5 . Bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com