A plugging device and plugging method for oil and gas pipeline reverse well drilling deviated wells

A technology for plugging devices and oil and gas pipelines, applied in safety devices, sealing/isolation, wellbore/well components, etc., can solve the problems of plugging devices such as heavy, heavy, and poor economy, and improve the effectiveness of plugging , The effect of facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

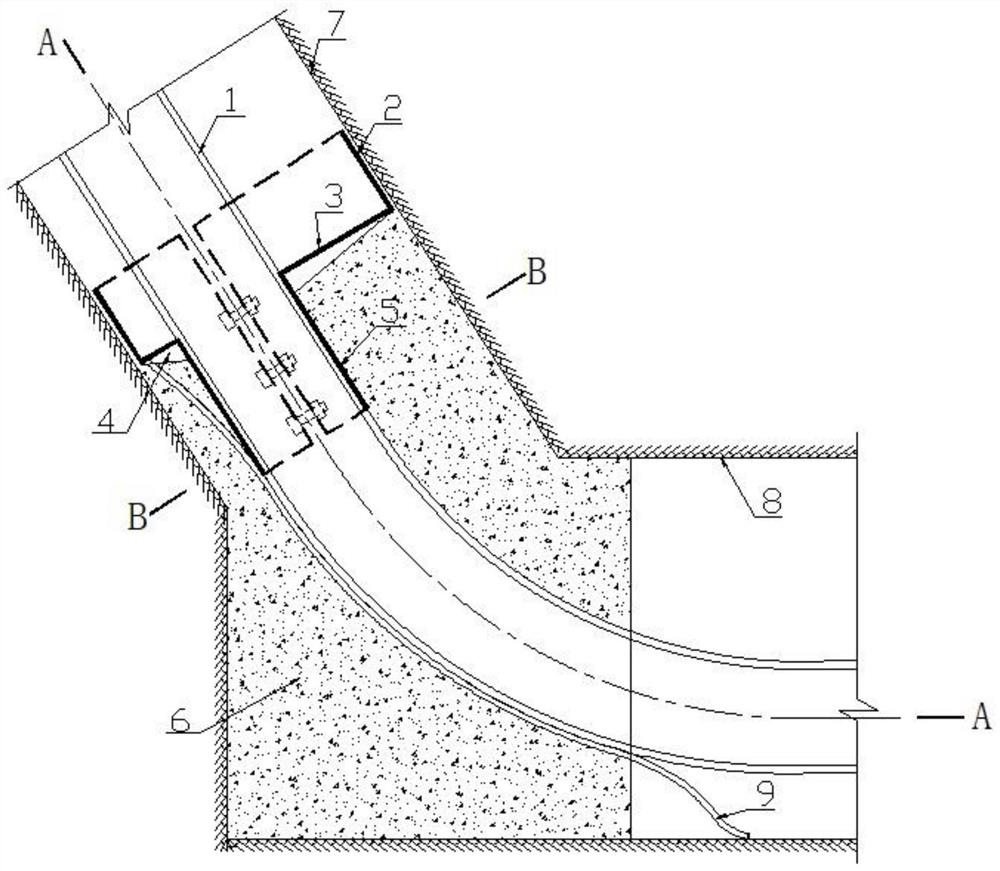

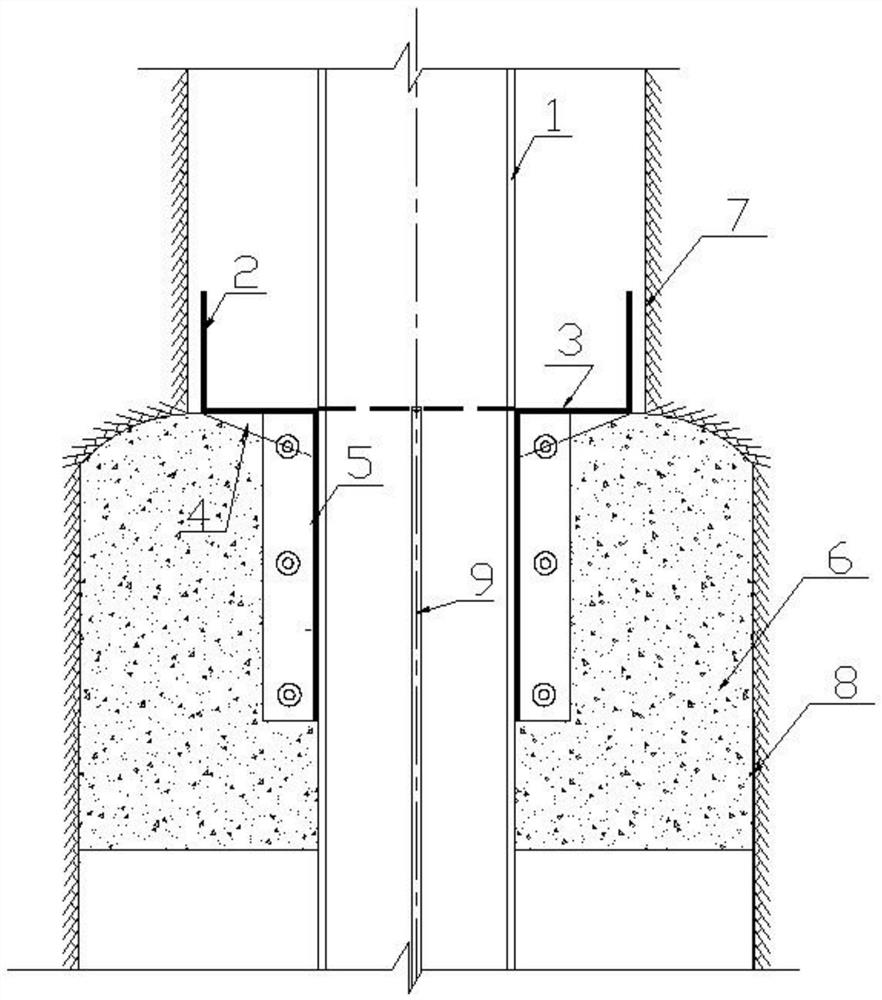

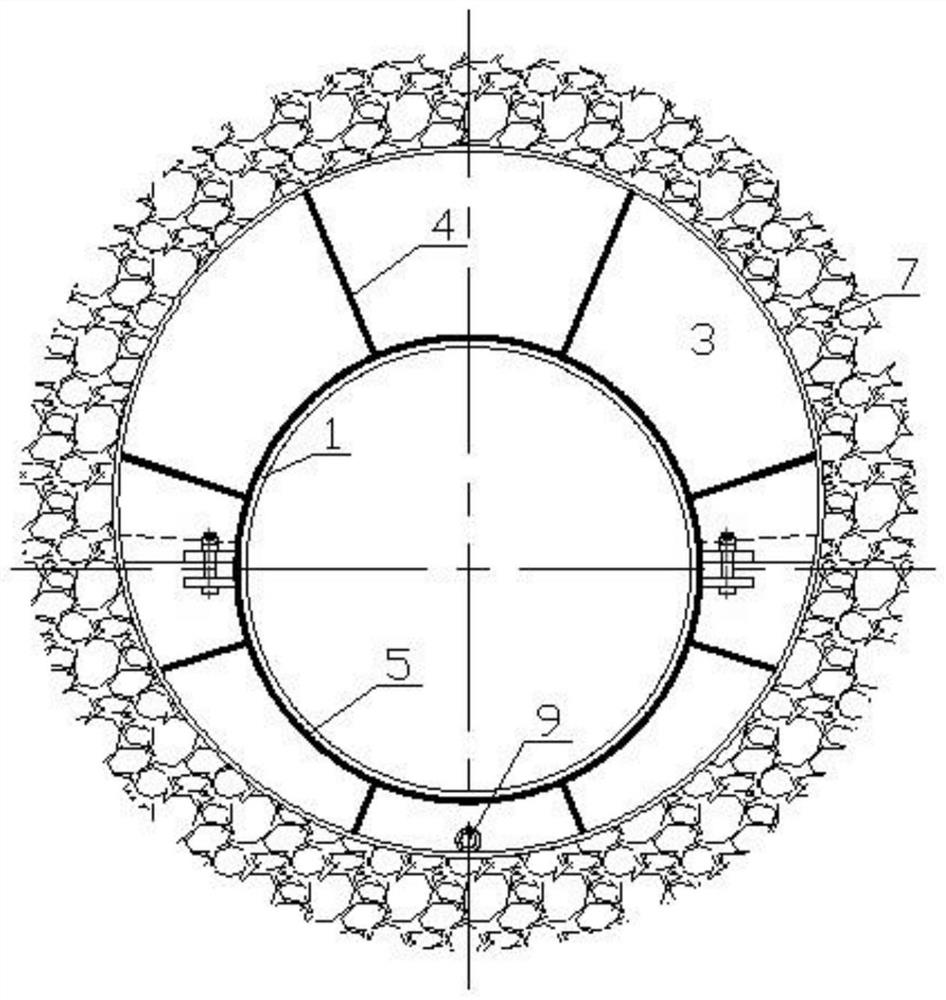

[0031] Such as Figure 1-3 As shown, what is described in Embodiment 1 of the present invention is a device for oil and gas pipeline back-drilling deviated well plugging, the device includes:

[0032] Tray 3, which is an inverted convex shape, includes a connected upper half cylinder 2 and a lower half cylinder 5, the tray 3 is two symmetrical pieces and is sleeved on the pipeline 1 through a detachable connector;

[0033] The stiffening plate 4 is arranged between the outer bottom end of the upper semi-cylinder 2 and the outer side of the lower semi-cylinder 5, and there are multiple stiffening plates 4;

[0034] A permanent support structure 6, which is arranged between the tray 3 and the tunnel rock wall 8, and the permanent support structure 6 is located below the upper half cylinder 2;

[0035] Drainage pipe 9, its inlet end is connected with the bottom of upper semi-cylinder 2, and the outlet end of drainpipe 9 is connected with drainage ditch in the tunnel.

[0036] T...

Embodiment 2

[0046] Embodiment 2 of the present invention describes a method for plugging deviated wells of oil and gas pipelines, the method comprising:

[0047] Step 1. Set the tray 3 on the outside of the pipeline 1 so that the tray 3 hugs the pipeline 1 tightly, and then fix the tray 3 with bolt connectors;

[0048] Step 2. Insert the drainage pipe 9 into the reserved hole at the bottom of the upper semi-cylinder 2 to transport the crack water in the inclined shaft to the drainage ditch in the tunnel;

[0049] Step 3, sealing the space between the outer side of the tray 3 and the raise drilling wall 7 tightly with a filler;

[0050]Step 4, pouring concrete between the tray 3 and the tunnel rock wall 8 to form a permanent support structure.

[0051] Further, in step 1, the tray 3 is fixed by bolts on the lower semi-cylinder 5 and reinforced by a plurality of stiffening plates 4 in the circumferential direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com