Flow channel port surface structure of high flow coefficient valve body

A technology of flow channel opening and surface structure, which is applied in the direction of diaphragm valves, valve devices, engine components, etc., can solve the problems of short service life, low flow coefficient and large flow resistance of diaphragms, so as to prolong service life, increase sealing area, improve The effect of the work environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

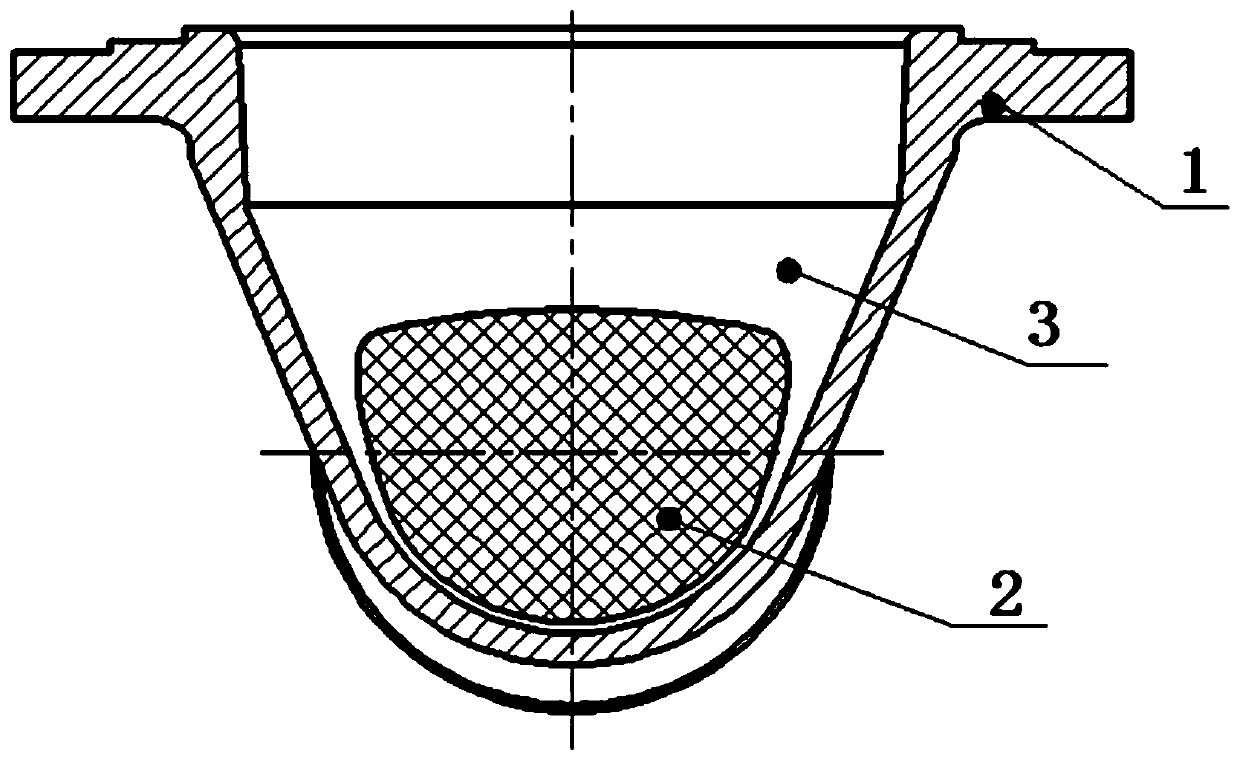

[0027] refer to figure 1 , a flow channel opening surface structure of a high flow coefficient valve body, which is the opening surface structure of the flow channel 2 opened on the valve body 1, the cross-sectional shape of the flow channel opening of the flow channel 2 is a left-right symmetrical structure, and the flow channel 2 The upper end of the cross section of the runner mouth is wide and the lower end is narrow, and the corners of the runner mouth cross section of the runner 2 are arc-shaped.

[0028] In this embodiment, the arc shape of the lowermost end of the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com