Chemical heat pipe based on reversible chemical reaction and physicochemical heat effect and heat transfer method

A chemical reaction and thermal effect technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of small heat and limited heat transfer capacity, and achieve the goal of increasing unit heat capacity, enhancing heat transfer, and improving decomposition rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

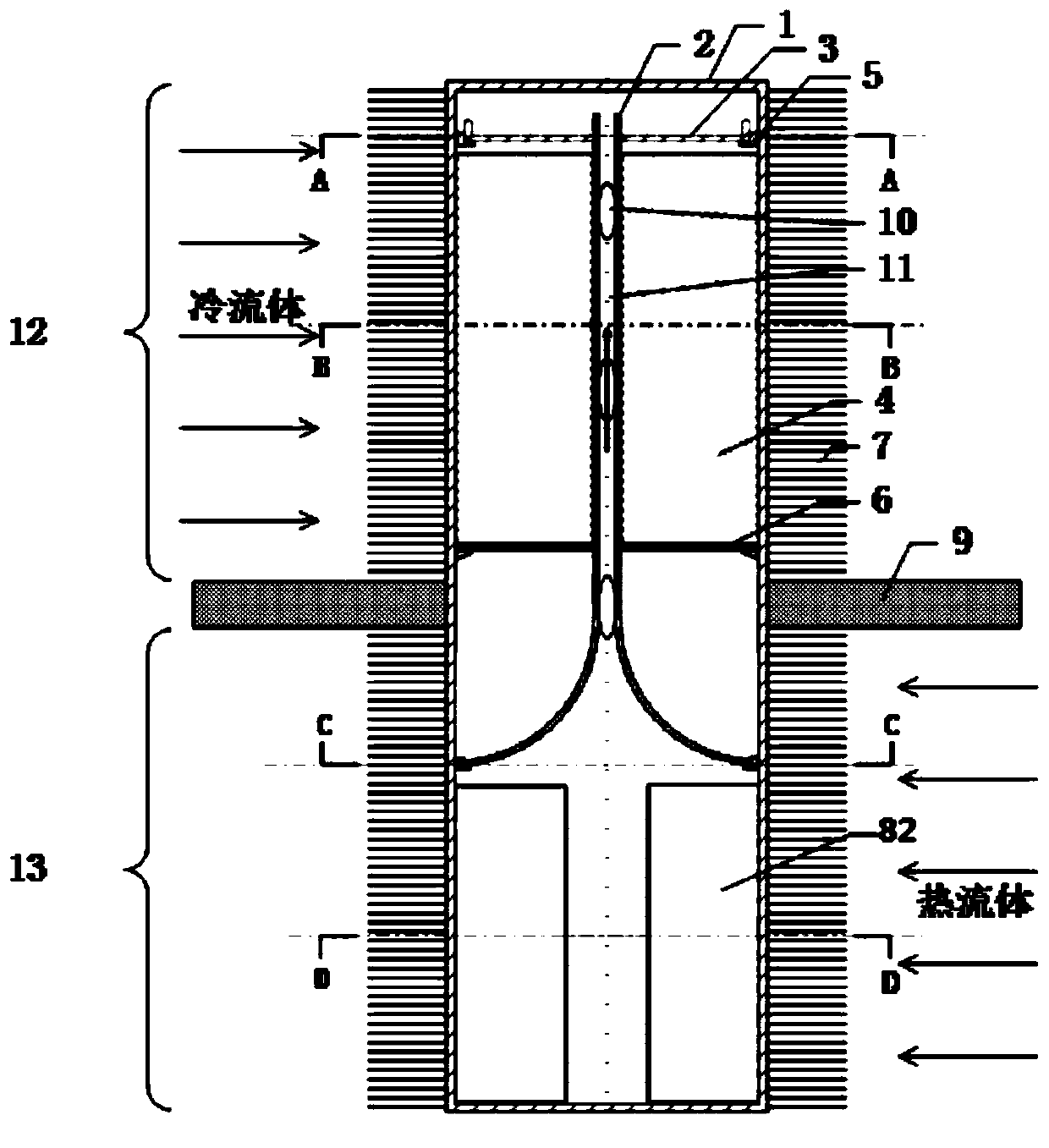

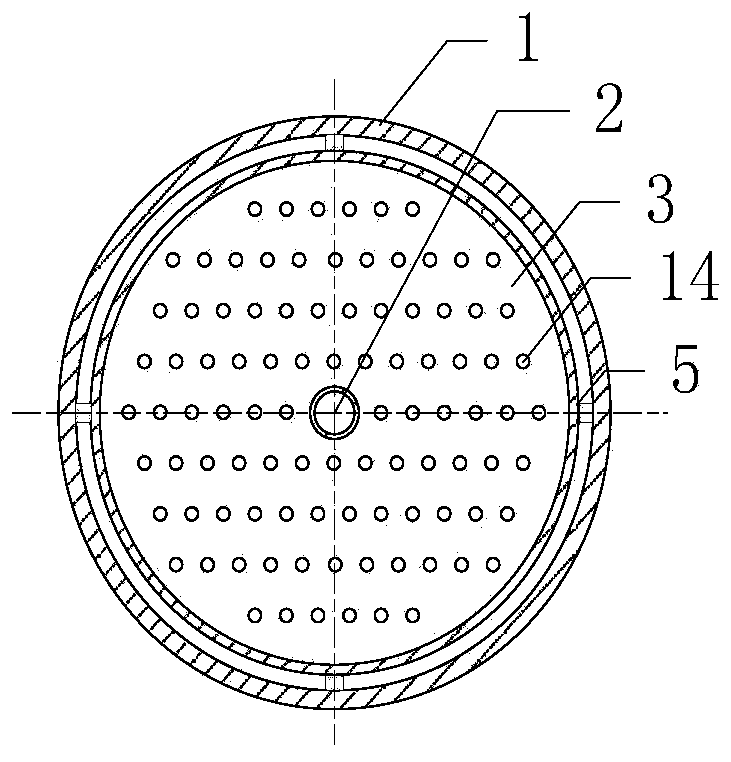

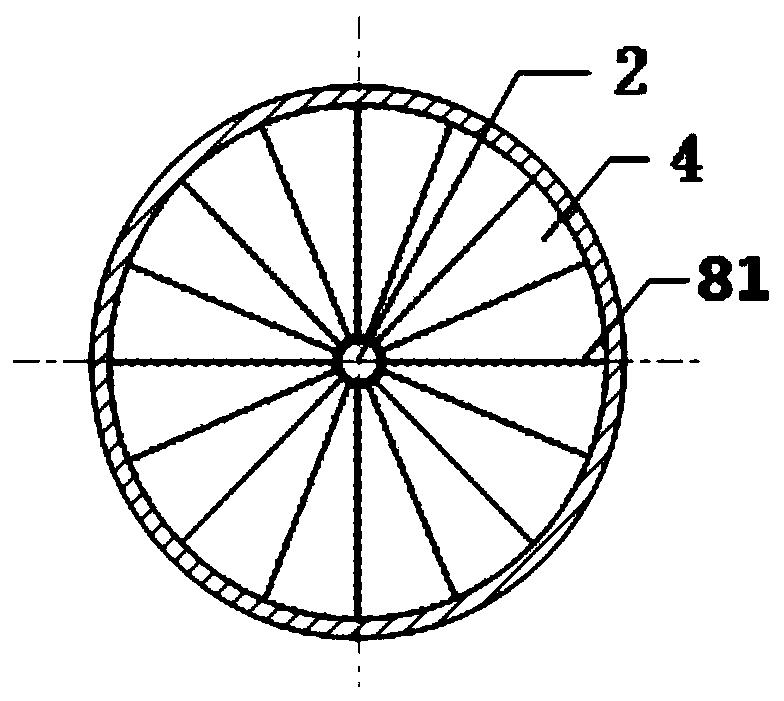

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as Figure 1-5 As shown, the chemical heat pipe based on the physicochemical heat effect of the reversible chemical reaction is divided into a synthetic reaction section 12 and a decomposition reaction section 13 of equal length along the axial direction. The internal structure of the synthetic reaction section 12 includes a liquid distributor 3, a packing chamber 4 and The packing support plate 5 and the vertical riser 2 are placed vertically inside the shell 1 and run through the liquid distributor 3 , the packing chamber 4 and the packing support plate 5 in the synthesis reaction section 12 . The upper opening of the vertical riser 2 is located in the gas phase area of the synthesis reaction section, and the edge of the upper end of the nozzle is higher than the edge of the liquid distributor 3 to prevent the liquid in the liquid distributor 3 from flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com