Testing device of coagulated frost depth and deformation non-uniformity of surface of porous asphalt mixture and method thereof

A technology of asphalt mixture and testing method, which is applied in measuring device, electromagnetic measuring device, electric/magnetic depth measurement, etc., can solve the problems of uneven frost depth and deformation on the surface of porous asphalt mixture, lack of etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

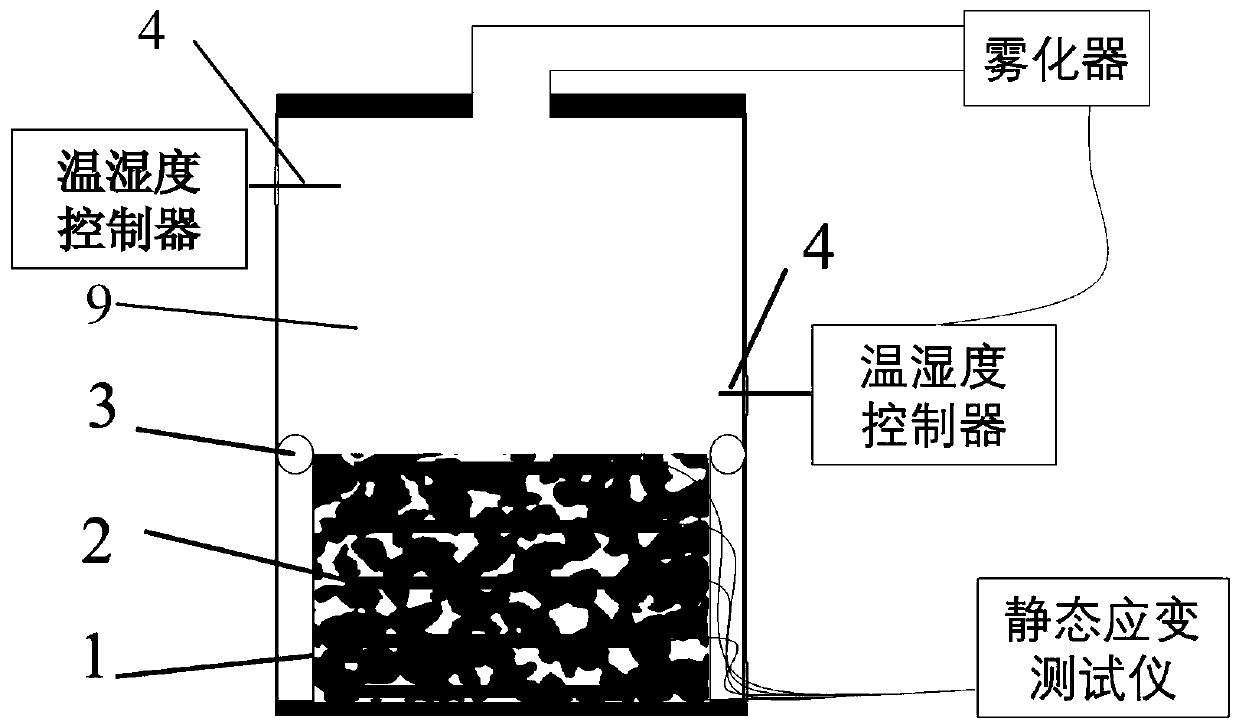

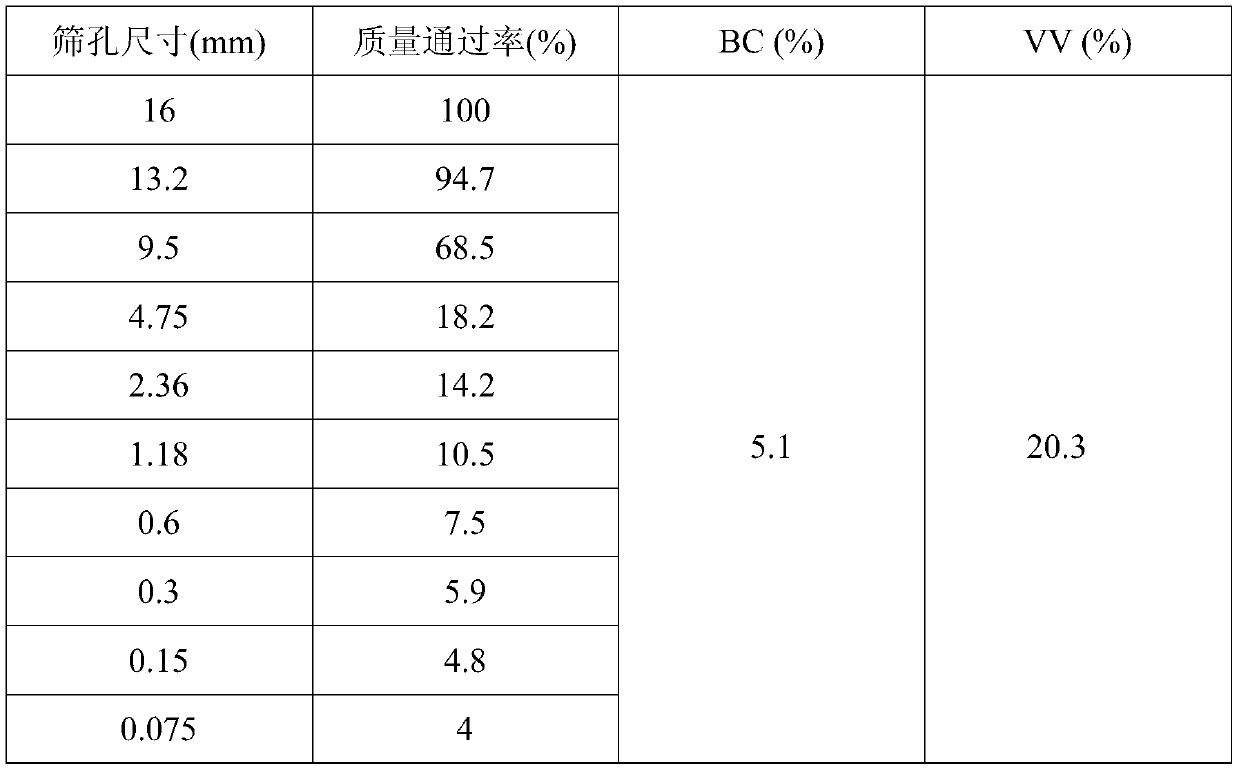

[0045] The following examples illustrate the frost deformation test method of porous asphalt mixture under different humidity. The porous asphalt mixture to be evaluated in the examples is OGFC-13, and its gradation, asphalt content BC, and void ratio VV are shown in Table 1.

[0046] The OGFC-13 that the embodiment of table 1 adopts

[0047]

[0048] (1) Specimen preparation and instrument arrangement

[0049] According to Table 1, the porous mixture Marshall specimen was molded, stored at room temperature for 24 hours, and then removed from the mold. The diameter of the porous mixture Marshall specimen was measured by a vernier caliper to be 101.6 mm, and the height was 63.5 mm. The specimen was scanned by the Discovery CT750HD medical CT instrument, and the scanned image was imported into the software Mimics to reconstruct the three-dimensional model of the specimen.

[0050] Then use 704 silicone rubber to paste five pieces of strain gauges 2 of model BX120-5AA equidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com